Instead of capacity decreasing because of rags, grit and debris steadily accumulating at the bottom of two digesters (334,000 gallons (1,264m3) and 183,000 gallons (693m3) respectively), the tanks’ contents at the city of Sparta (situated between Milwaukee and Minneapolis) are now comprehensively mixed by Landia’s GasMix system.

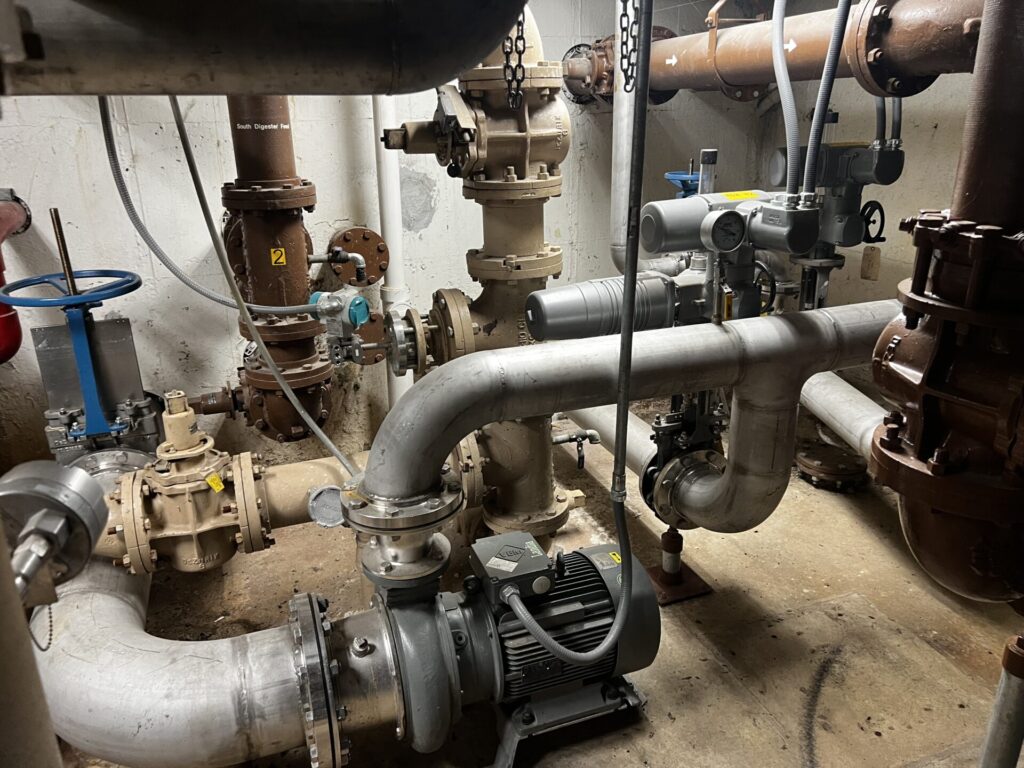

A simple, yet highly effective design, comprising the proven Landia Chopper Pump (invented by Landia in 1950), and strategically-angled venturi nozzles, all mechanical equipment can be accessed on the outside of the digesters for easy maintenance.

Sparta’s Wastewater Treatment Plant Manager, Ed Hanson, commented:

“Our old, basic mixing system just blew air upwards in the digesters, which wasn’t very efficient. Also, we couldn’t get to it to carry out maintenance or make repairs without draining the tanks down. This can take you offline for a long time, which nobody wants when trying to produce biogas.

“Eventually, the old mixing system was failing; just providing some minor recirculation, with very little actual mixing taking place. When it became time to drain down the first digester and install the Landia GasMix, we found a huge amount of debris inside.”

Built in the 1950s, Sparta’s wastewater treatment plant serves 10,000 people in what is known as the ‘Bicycling Capital of America’. In addition to domestic wastewater, the WWTP also receives effluent from a large food processing plant, a major dairy, plus leachate from the county’s landfill, and septage brought in from hauliers. Although the WWTP has some screening, there is very little pre-treatment in place before it reaches the inlet.

“The Landia GasMix installation went very well,” continued Sparta’s Ed Hanson. “Landia were here to help every step of the way, especially as this was a tight and tricky challenge with very limited space for the new mixing set-up. We had to move some of our recirculation pumps.

‘Grabbing the Gas’

“At the start-up of the new system, we could see immediately that the Landia GasMix created plenty of turbulence and did a great job grabbing the gas from the top of the digester. Everything went smoothly, so six months later, we went ahead with installing another Landia GasMix for our second digester. Although it was a challenge with the space restrictions we have on this part of the plant; everything slotted into place, and the new mixing system has been working just fine, with no issues at all.”

Heat produced from the AD process is now utilized for heating the digesters to their optimum temperatures, with the Landia GasMix ensuring that sludge is mixed comprehensively to significantly enhance the destruction of volatile solids and boost biogas yields.

‘Far More Methane is Being Produced’

“We’ve certainly seen that our gas bills are not as much as they were the year before, and we’re much more eco-friendly now,” added Ed Hanson. “We have long cold winters here, so with the old mixing system, you could see everything drop back down to nothing as temperatures dropped, but since our upgrade, the gas holds much, much longer. We can see that far more methane is being produced, and faster.”

Unlike the previous mixing system where all mixing components were trapped inside the digesters, Ed and his team of four colleagues can now carry out visual and audio checks on the externally-mounted pumps, making any adjustments as necessary.

‘Good Digestate Product’

“Maintenance is easy, and we also have a good digestate product at the end of the process,” continued Ed.

“This provides very useful nitrogen for farms in the county as a fertilizer, and saves them money, which is always a positive thing. We’re now looking at how we can improve consistency, so that there’s less water and more product. We’re working on getting the compaction levels just right so that it is easier for farmers to apply to land.

“The new mixing system was a long time coming, but it has been well worth the wait. We’re now producing biogas as we should be, because the digester sludge is being mixed comprehensively by the Landia GasMix.”