Part of the ClydeUnion Pumps (CUP) Glides range, Uniglide-e split pumps have a capacity of up to 4,000 m3/hr (17,600 USgpm), a delivery head of up to 200 m (670 feet), and operate at speeds of up to 1,800 rpm. Their innovative hydraulic design and the application of a special internal coating provides low NPSH, stable characteristics, and high efficiency – contributing to low running and whole life costs. Typical applications include water treatment, processing, and building services sectors, or any task requiring a highly energy-efficient and economical pump.

Designed for reliability

Uniglide-e pumps feature a keyless drive design that eliminates the impeller key, which is a common cause of shaft failure due to fretting and fatigue failures. While the keyless drive isn’t a new technology, it is more usually found on high-end, high-speed turbine applications and is seen as a highly effective method of guaranteeing maximum power transmission without the risk of fatigue failure.

These pumps are also equipped with a high tensile shaft designed to minimize dynamic shaft deflection and provide an ample safety factor in rotation speed, ensuring extended shaft life. Radial thrust is reduced by utilizing a double volute casing design on all but the smallest frames; offering improved efficiency, minimized vibration, and extended bearing and seal life.

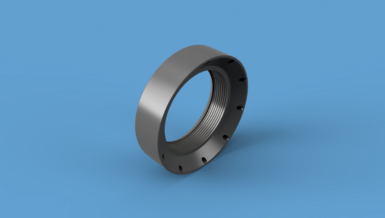

Seal integrity is assured thanks to a unique adaptor design, which allows the fitment of all major supplier’s cartridge seal assemblies. Cartridge seals and bearings can also be changed in a fraction of the time taken on a conventional unit. The Uniglide-e’s split casing design further simplifies maintenance by allowing access to the pump rotor without disturbing the pipework or the driver.

Customer choice

With the potential to bring benefits to many industries, Uniglide-e pumps come in a wide range of configurations. Material specifications are available for non-corrosive and corrosive applications, including seawater, with WRAS and NSF coatings available for potable water projects.

Horizontal and vertical configurations, radial and thrust bearings, and clockwise or anti-clockwise rotation are also available. Uniglide-e pumps are designed for both 50Hz and 60Hz markets.

The Uniglide-e is part of the innovative CUP Glide range. The complete Glide range allows customers to choose from more than 170 frame sizes with coverage that extends up to 20,000 m³/hr (88,000 USgpm) and heads up to 350m (1,100 ft).