Martin Stümpfle, Product Management Wangen Pumps, explained: “We are constantly seeking ways to improve pump performance and benefit our customers’ operations. The technical improvements we have made to our popular Twin NG pump deliver advantages ranging from contamination risk reduction to longer service life.”

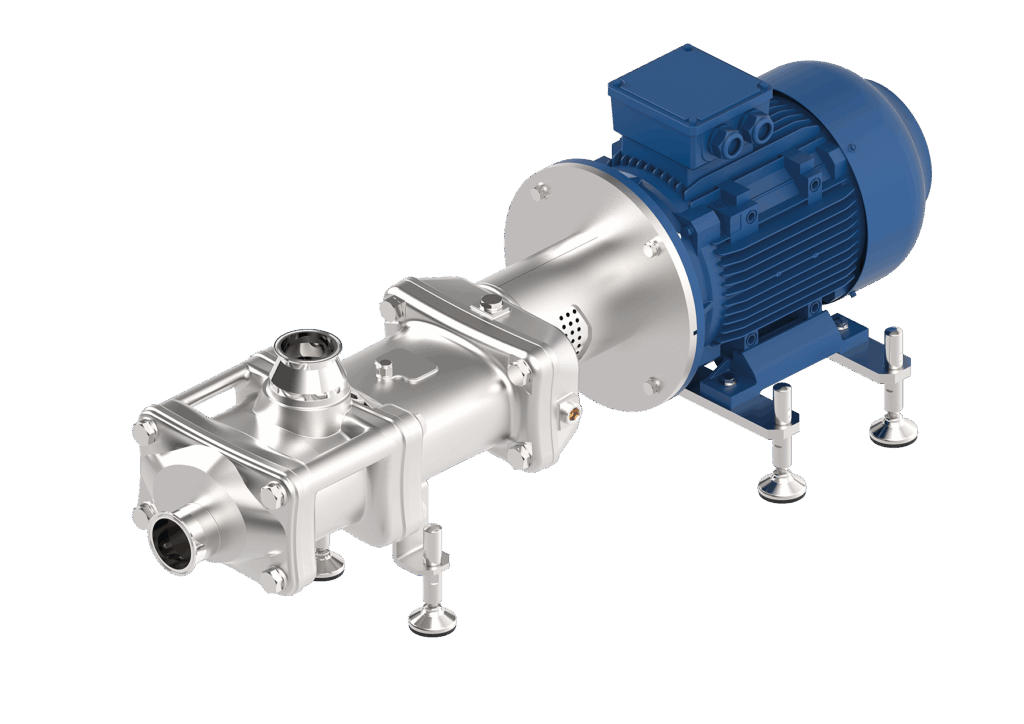

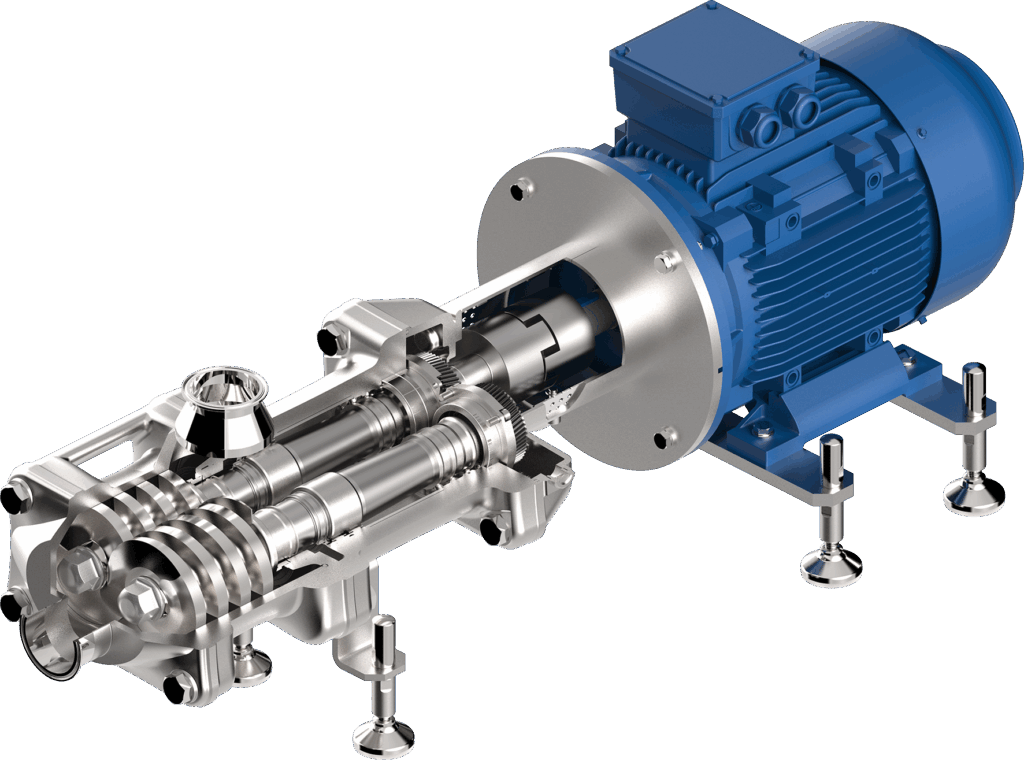

Twin NG screw pumps are designed to reliably handle low to highly viscous, volatile, or gaseous products in applications that demand maximum hygiene and efficiency. Available in several sizes, the TWIN pumps offer a maximum flow rate of 200 m³/h and a maximum differential pressure of 25 bar.

Improved TCO

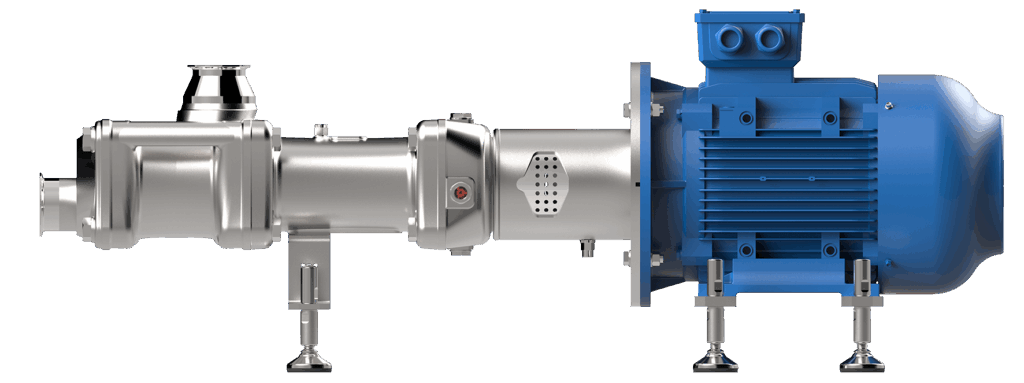

The first design enhancement involves replacing the Twin NG’s motor coupling with a lantern coupling. This innovative feature prevents pump shaft misalignment, which reduces stress and vibration, thereby enhancing the lifespan of the pump and motor. With less wear on pump shafts and bearings, maintenance requirements are minimised, and service intervals are extended. When maintenance is necessary, it is easier to perform since no shaft alignment is required. This lantern design thus lowers the total cost of ownership (TCO) and optimises uptime.

Another benefit of the new lantern design is smoother operation in demanding conditions, particularly where the Twin NG is used to pump viscous and abrasive fluids under high pressure. The lantern coupling also enables better sealing arrangements, minimizing leaks and the risk of product contamination.

Better hygiene

The second design improvement to the Twin NG pump is the option to install the pump using hygienic machine feet instead of a base plate. These feet are much easier to clean than traditional base plates because they minimise surfaces where dirt and bacteria can accumulate, greatly reducing the risk of hidden contamination associated with solid base plates. The individual feet also facilitate more effective wash-down and drainage, without the need for elaborate drainage slopes and holes.

Like the pump’s lantern coupling, the machine feet help to dampen noise and vibration, reducing wear on the pump and associated equipment. Individually adjustable, machine feet enable precise levelling, making it easier to align the pump with existing piping and reducing the risk of errors during installation. The feet also provide better access to the pump during routine maintenance, whereas base plates may require disassembly before vital components can be reached. Machine feet therefore improve pump availability by reducing servicing time.

Additional benefits of machine feet include a better ability to compensate for thermal expansion, preventing damage to the pump and piping, as well as better stability during maintenance at the pump’s fluid end. Furthermore, machine feet generally require less room than a base plate, which is important in confined spaces. Eliminating the base plate also reduces material and fabrication costs, making pump transportation and handling easier.

“The improved Twin NG exemplifies our commitment to listening to our customers, understanding their business needs, and refining our pump designs to deliver improvements in performance, cost and serviceability that contribute to greater overall efficiency and productivity,” concludes Martin Stümpfle.