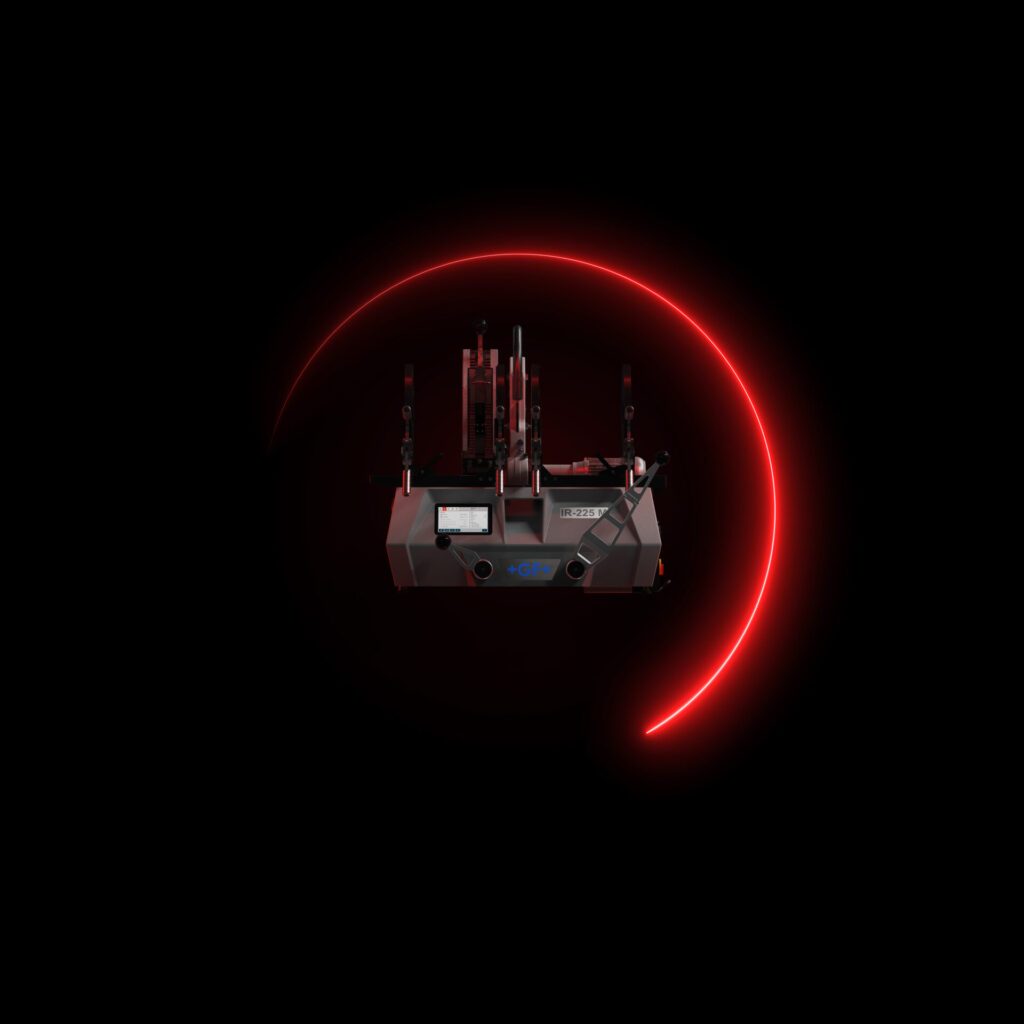

Building on the success of the IR-63 M, GF set out to further improve infrared pipe welds in industrial applications. Thanks to design improvements resulting from intensive research and in-depth material knowledge, the IR-225 M enables shorter cooling times. At the same time, it has extended the range of weldable materials in the same unique and application-oriented dimension range. Experts from the development team will unveil the compact, robust, and efficient fusion machine in a webinar on 4 June 2025.

Bastian Lübke, Head of Jointing Solutions at GF, is proud of the achievement: “For over 30 years, we have continuously improved infrared fusion with an ever-faster process and a growing range of dimensions. Last year, the IR-63 M already made a big leap forward with its usability, connectivity, and speed. As its big brother, the IR-225 M expands on these improvements with even more innovative features and increased efficiency. We look forward to presenting our next-generation fusion machine in detail next month.”

GF’s infrared fusion machines deliver contact-free, high-quality welding of materials such as PVDF, ECTFE, PP-H, PP-n, PE100, and PVC-U. IR fusion technology is especially valuable in industries like chemical processing, microelectronics, and water treatment, where long-lasting and reliable operation is essential. The machine-controlled process streamlines installation, minimizing steps and significantly reducing both preparation and cooling times. Since introducing contact-free IR fusion technology in 1992, GF has been at the forefront of its ongoing development and innovation.