A wholesale company for chemicals and fuels, based at a port storage facility in the Dominican Republic, was seeking a reliable solution for level detection in lorry tanks. The primary focus was the monitoring of sulphuric acid, a highly corrosive medium that places special demands on the durability of the equipment used.

The aim was to avoid manual inspections and to protect personnel from direct contact with the aggressive chemical. Additionally, the filling process needed to be automated and reliable – even under the challenging environmental influences caused by the tropical climate.

Reliable sensor technology: resistant to chemicals, climate, and corrosion

In addition to resistance against aggressive media, the climatic conditions at the installation site were a crucial factor: The year-round tropical and humid climate, with temperatures around 30 °C and consistently high humidity of approximately 80%, places considerable strain on the deployed equipment.

Combined with the use of sulphuric acid, this led to particularly high corrosion stress – one of the greatest challenges for the sensor technology.

The capacitive level sensor RFnivo® 8200 from UWT was chosen for this demanding application. Its robust rod design, equipped with a 250 mm long probe made of stainless steel 1.4404 (316L) and a high-quality PFA coating, offers maximum resistance against aggressive and corrosive media such as sulphuric acid. In addition, the integrated active build-up compensation ensures reliable measurement results – even with adhesive or viscous liquids.

The RFnivo® 8200 is designed for process temperatures up to 400 °C, features a pressure-resistant IP68 aluminium housing, and is suitable for ambient temperatures up to 85 °C – making it ideal for these challenging operating conditions.

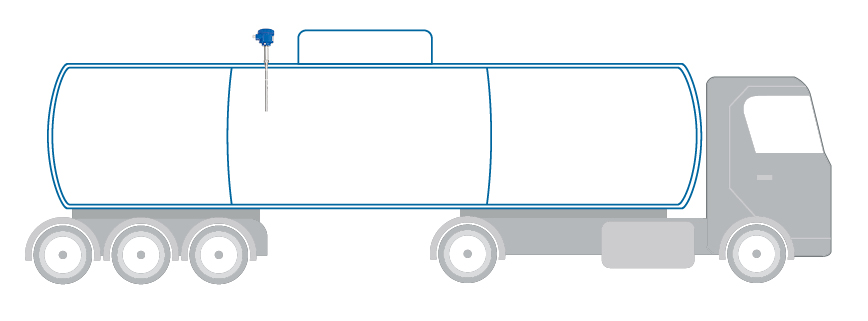

To ensure safe level detection, the wholesale company installed the sensor at the top of the lorry tanks to precisely and maintenance-free detect the maximum fill level.

One sensor – many advantages

The RFnivo® 8200 also stands out with the following features:

- Adjustable sensitivity from DK ≥ 1.5

- Flexible connection and installation options

- Wide supply voltage range (12–250V AC/DC)

- Various signal outputs (relay, transistor, Profibus PA)

- Simple configuration via display, DIP switch or PACTware

- Ex certifications such as ATEX, FM, CSA and INMETRO for use in potentially explosive atmospheres

With the RFnivo® 8200, UWT offers a robust, safe and climate-resistant solution for reliable level detection in the chemical industry, as well as in industries such as petrochemicals and oil & gas. In the tropical climate of the Dominican Republic, the sensor ensures a reliable and safe filling process for lorry tanks – resistant to aggressive chemicals such as sulphuric acid, high humidity, heat, and particularly to strong corrosion.