Production of pharmaceutical drugs presents difficult challenges for process instrumentation used to monitor and optimize the process. Typically drug production processes require devices able to cope with low flow rates and constructed from ultra-pure materials so as to maintain hygienic, sterile, and sanitary conditions.

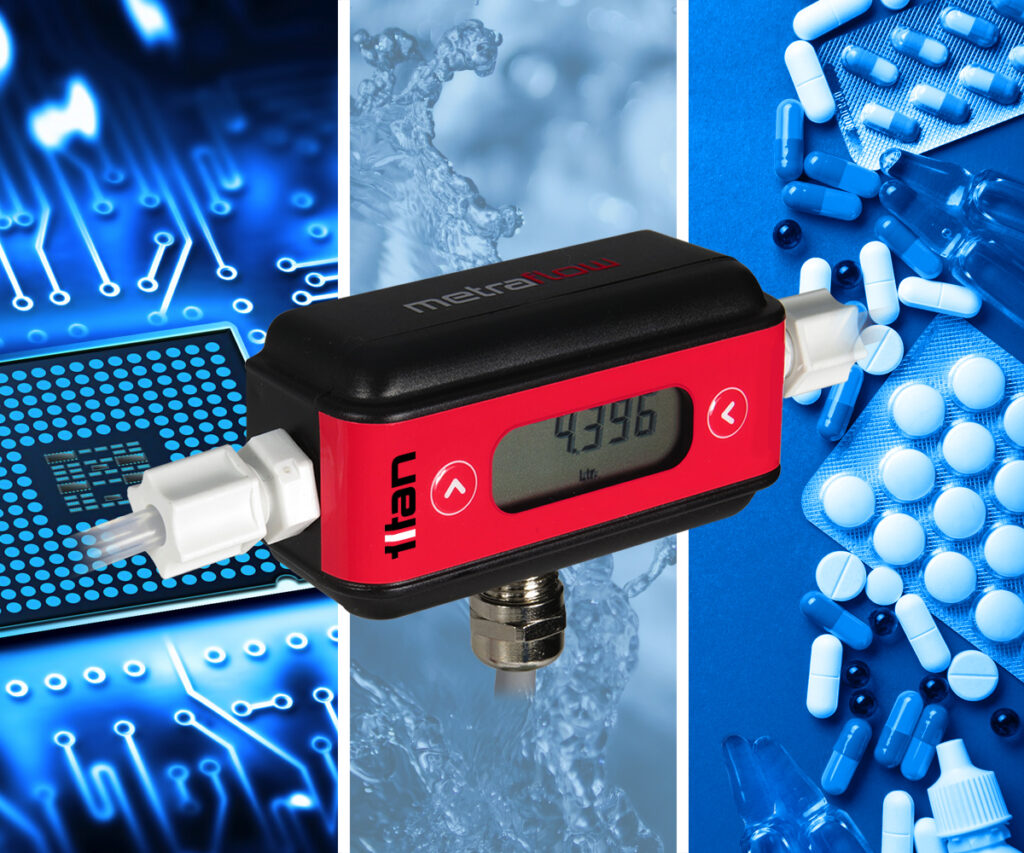

Clean bore flow measurement devices such as Titan Enterprises’ Metraflow® ultrasonic flowmeter, designed primarily for ultra-pure water dispensing applications requiring a high degree of cleanliness, offer the ideal solution for the pharmaceutical industry.

Ultra-pure water – water that has been purified to very strict specifications – is an important component for industries across specialist markets where impurities can cause product contamination or impact process efficiency.

Ultra-pure water (UPW) systems, typically used in production and cleaning processes within the pharmaceutical industry, require a selection of technologies and equipment that preserve the purity of materials. It is crucial that any flow measurement device used in UPW systems can cope with low flow rates and are constructed from ultra-pure materials that cannot contaminate the liquids being measured. Maintaining hygienic, sterile, and sanitary conditions within these processes are critical.

Pharmaceutical and biotechnology facilities use UPW as a cleaning agent and a diluent for multiple-dose injections as well as an ingredient in products. Water-free of endotoxins, microbes, and viruses is essential in these applications and others such as inhalation therapy products, internal irrigation therapy products, and bulk preparation of medicines.

The Metraflow® uses Titan’s patented ultrasonic time of flight technology to accurately measure liquid traveling through the clear, single, clean bore measurement flow tube constructed from high-performance Perfluoroalkoxy Alkane (PFA) polymer.

Neil Hannay, Senior R&D Engineer with Titan Enterprises, says: “Ultra-pure water can become easily contaminated by atmosphere passing through tiny leaks or diffusing through thin wall polymer tubing used for flow measurement. PFA polymer was chosen specifically as an advanced tubing option for the Metraflow® as it offers excellent chemical inertness, is able to withstand damage by dangerous contaminants, prevents accumulation of particles, and has an ultra-high grade of purity.”

Titan’s Metraflow® is non-intrusive with no internal moving parts, designed to precisely monitor process flows at temperatures from 10ºC to 60ºC (140ºF) and pressures up to 27 bar. In addition, this non-invasive single tube ultrasonic flow meter gives a wide operating flow range with an accuracy of +/-0.5% FSD and repeatability across flow ranges from 20 to 5000 ml/min.

In addition, Titan Enterprises has released a new software interface for its Atrato and MetraFlow ultrasonic flowmeters to give customers improved functionality, increased versatility, and advanced operational features.