To avoid the risk of microbial contamination, environmental monitoring in pharmaceutical manufacturing facilities is controlled through aseptic processing, comprising microbiological test methods. In order to guarantee proper functioning of these air sample devices, regular verification is necessary.

Application

The control of microbial contamination in clean rooms and other controlled environments is critical for all contamination-sensitive production facilities (e.g. in terms of patient risk in pharmaceutical production).

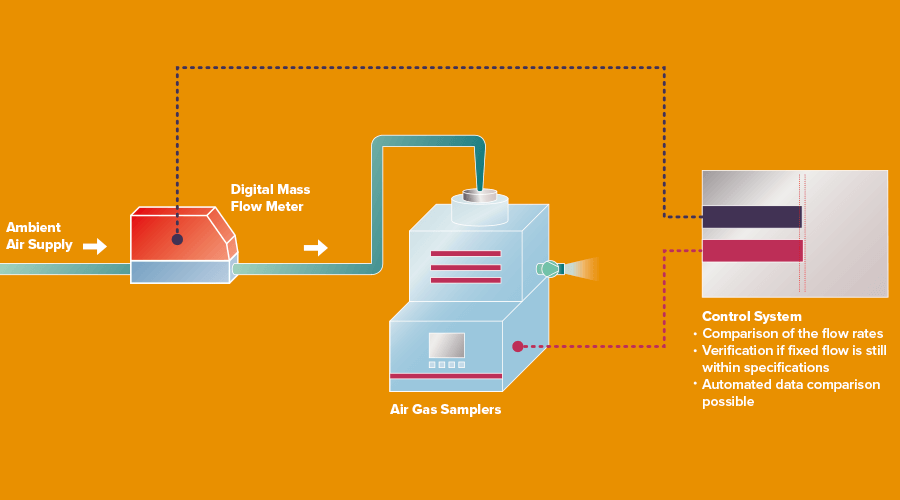

Air samplers are used to monitor the quality of the environmental air. The devices operate with agar plates which are sprayed with a constant flow of ambient air. These plates are later analyzed with regard to microbial contamination in the production area.

In order to guarantee monitoring at a constant flow rate, the environmental air sample devices must be checked at regular intervals. In this context, reliability, repeatability and traceability of the testing instruments are key parameters for a valid measurement.

Challenge

For a reliable inspection of the microbial environmental air gas samplers, the testing instruments must guarantee an accurate and reproducible measurement over a long period of time. Measurements must be traceable at all times.

Solution

The MEMS technology of the mass flow meters from Vögtlin provides high accuracy and repeatability. Plugand- play functionality and no warm-up periods improve user productivity.

Vögtlin mass flow meters and controllers have a unique way of compensating for changes in ambient and gas temperature, which strongly improves the repeatability. This ensures a long-term stability without any drift.

The devices also allow to record all measurements with the use of digital control systems for later traceability. Gas flow readings are taken 12 times per second and can be stored using data logger software.

Spray dryers come in all sizes from small test units in Pharma development laboratory, to large production systems.

Vögtlin can control flow from 0-10 mln/min (smart series) up to 1400 ln/min (d·flux series) and offer solutions for most sizes and models.

Key Features

★ High repeatability & reliability

★ Long-term stability

★ Plug-and-play functionality

★ Data logging of measurements

★ Compact unit with high-quality components

Interfaces

★ Analog

★ Modbus RTU

★ Profibus DP-V0/DP-V1

★ Profinet RT

★ EtherCAT