The pharmaceutical industry is a sector of extremes: new drugs increase the life expectancy of patients, prices for groundbreaking therapies regularly break records, and the consumption of resources also exceeds that of other industries manifold. The pressure on pharmaceutical manufacturing companies is all the greater: life-saving drugs must be brought to market in high quality and within the shortest possible time, while the underlying processes should be significantly more efficient.

At the same time, energy prices are rising, many countries are increasing their CO2 taxes, and companies want to meet their own sustainability targets by self-defined deadlines. Technology providers can play a key role here by proactively advising their customers and showing them ways to make their processes more resource efficient. As practical experience shows, small upgrades are often enough to significantly reduce energy and media consumption and to gradually approach the goal of more sustainable pharmaceutical production.

Increasing efficiency with analyses

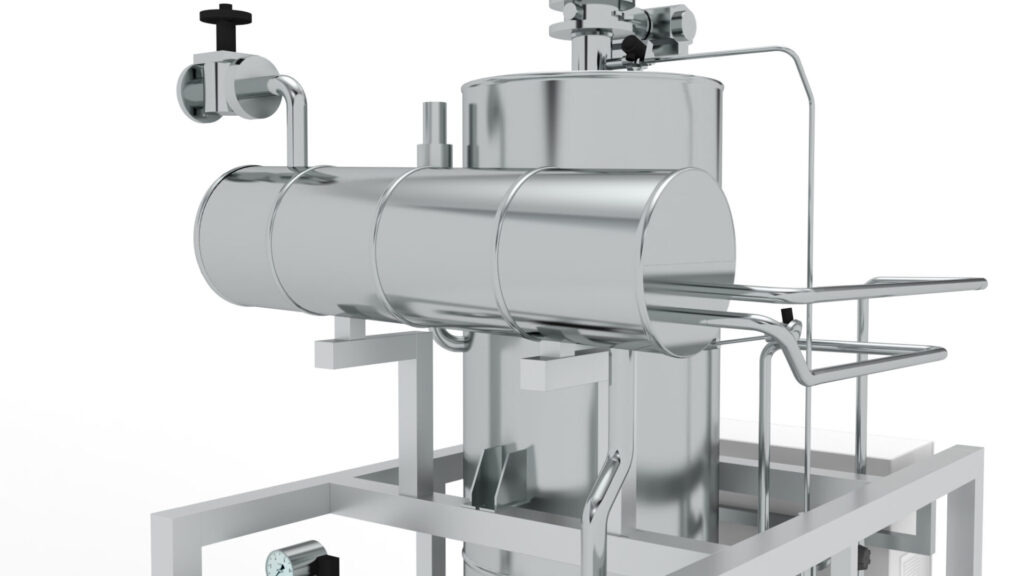

A good example is the generation of pure steam, which is used to sterilize pharmaceutical products and surfaces. The single-column PSG from the Syntegon subsidiary Pharmatec is a compact and robust system with a stainless-steel construction, low mechanical stress on the heat exchanger, a low tendency to form deposits, and a bell-shaped separation system. The standard configurations cover the entire capacity range of up to 5,000 kilograms per hour. Although the system is so compact, it still offers optimization potential at various points.

Depending on the operating conditions, pharmaceutical manufacturers can save up to 39 percent water, up to 30 percent cooling water, and up to 13 percent steam. The wastewater can even be reduced by up to 68 percent. The key to these successful savings is a preliminary analysis in which the Pharmatec service team carefully examines the individual process parameters together with the customer. This allows the team to calculate the customer-specific greenhouse gas emission savings in accordance with the relevant standards. Pharmaceutical manufacturers can see at a glance how much water and energy they are currently using, where they have opportunities for savings, and what specific measures they can take to minimize costs and emissions.

Savings during blow-down and sampling

How exactly can the desired increase in efficiency be achieved? Let’s take, for example, the reduction of the blow-down quantity, i.e. the discharge of residual materials by discarding boiling water. Introducing a timer is an effective measure to control the blow-down quantity individually. This requires the installation of an automated shut-off valve and the associated adjustment of the software parameters and the process, as well as a new visualization of the timer. As a result, manufacturers can reduce their media losses through blow-down by up to 96 percent – which, regardless of the size of the machine and the type of operation, can lead to savings in the five-digit euro range.

Financial savings are even greater when the pure steam is sampled physically. The samples are often used for continuous conductivity measurement and are extremely critical from an energy standpoint. Automated, periodic closure of the system results in significant energy savings. Adjustments to the sampling configuration can reduce the loss of incoming water, heating steam, cooling water, and wastewater by up to 75 percent. Even when quality assurance requirements are particularly stringent, individualized solutions can be found.

New preheater and setback principle

Another way to achieve substantial savings is to install a preheater. It preheats the feed water, enabling pharmaceutical manufacturers to reduce the heating steam input for the entire process. Alternatively, and depending on the operating conditions, between ten and 15 percent more pure steam output can be generated with the same heating steam input. The lower thermal stress also extends the service life of the column.

As with many heating systems, a night setback for production-free periods notably reduces energy consumption in pure steam generators. The pure steam pressure is decreased either automatically or at the push of a button, while the loop remains hot and can be quickly returned to operating conditions. A program change with a new parameter set is required to utilize this potential; the exact circuit is adapted to the pharmaceutical manufacturers’ individual needs. Mechanical changes are not necessary.

Focus on proactive consulting

To show which options are available in each individual case, Syntegon takes a proactive consulting approach. Its experts approach customers directly and analyze the optimization potential of their pure steam generators. It is important to consider different perspectives, because energy officers have a different view of the analysis results than plant engineers or the purchasing department. Ideally, all objectives and wishes should be fulfilled – from cost reductions and CO2 savings to compliance with standards.

If the customer is interested, a detailed analysis follows. It includes suggestions for improvement in the form of upgrades and determines the amortization period. For the changes described above, this period is generally between one and two years maximum. For the modernization project itself, Pharmatec offers the following advantages: the system runs at the same or improved performance after the modification, as the previous operating mode is checked and optimized as part of the adaptation. In the unlikely event that this does not occur, Syntegon will dismantle the modification on its own responsibility, thus preventing risks such as machine downtime right from the start. In addition, modification documents are provided as standard, which considerably speeds up the system’s requalification. In addition, the experts provide their customers with a detailed analysis that is well suited as evidence for regulatory authorities.

Working together for more sustainability

The positive customer feedback shows that pharmaceutical manufacturers are increasingly relying on technology partners to help them save resources and increase efficiency by providing proactive advice. The more seemingly small steps technology providers and manufacturing companies take together, the faster they can achieve their sustainability goals. Companies like Syntegon that invested in their own sustainability strategy early on have a clear advantage. They are increasingly offering energy-saving options for their equipment and developing compelling upgrades and innovations.