In chocolate production, Chocolats Halba uses only fair-trade cocoa beans. These are refined in the inhouse roasting plant and then processed into chocolate at the new production site in Pratteln together with other ingredients.

Measurement Requirements

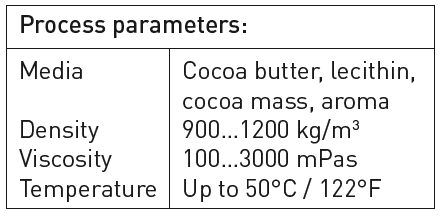

During production the cocoa mass obtained from the cocoa beans is mixed with other ingredients such as milk powder, cocoa butter, sugar, lecithin and flavourings to form a creamy mass. Rolling mills then crush the solids in the coarse chocolate mass to a grain size of 0.018 mm. In order to further refine the chocolate and to remove aroma substances from the fat, the now almost finished product is finally “conched” for several hours at temperatures of up to 90°C / 122°F. Only then do the well-known taste nuances unfold.

These are essentially determined by the use of the ingredients. In order to ensure the high quality of the chocolate, the chocolate manufacturer must add all liquid ingredients such as cocoa butter, lecithin and flavourings in the correct proportion to the cocoa mass.

In particular, cocoa mass and lecithin are sometimes very viscous and are therefore, run at higher temperatures. Chocolats Halba was looking for appropriate process instrumentation for high accuracy dosing and mixing of the individual media.

KROHNE Solution

KROHNE supplied a total of 11 Coriolis mass flowmeters for various dosing tasks:

- 4 OPTIMASS 1400 C with twin bent tube made from stainless steel (size DN25)

- 4 OPTIMASS 7400 C with single straight tube made from stainless steel (size DN25) connected to a heating jacket

- 3 OPTIMASS 7400 C with single straight tube made from titanium (size DN15) connected to a heating jacket

The mass flowmeters in straight tube design are ideally suited for hygienic applications. They are self-draining and cause minimal pressure loss. Due to the low flow velocities of the media to be measured, most measuring instruments are smaller in diameter than the process line.

While the OPTIMASS 1400 C measures non-critical dosing applications with lower viscosity such as cocoa butter, the OPTIMASS 7400 is used for flow measurements of highly viscous media such as cocoa mass due to its single straight tube. In addition, the version with titanium measuring tube offers improved zero-point stability in particularly critical dosing applications and thus even higher accuracy (up to a deviation of ±0.05% of measured value).

Customer benefits

KROHNE’s mass flowmeters enable chocolate ingredients to be measured accurately and with long-term stability. This enables the customer to produce the chocolate specialties in consistently high quality according to their recipe. Due to the low-pressure loss of the straight tube devices, the flowmeters do not cause an increase in pump capacity, which saves costs. For temperature-critical measuring tasks, the company benefits from the integrated heat tracing of the OPTIMASS 7400, available ex works from KROHNE. This prevents changes in the viscosity of the media and loss of efficiency.

Products Used

- Coriolis mass flowmeter with twin straight tube design for universal hygienic applications

- Mass, density and volume flow of gases and liquids; maintains operation even with entrained gas of up to 100%

- Many hygienic connections (DIN, SMS, Clamps etc.

- Coriolis mass flowmeter with single straight tube design for advanced food applications with viscous media

- Mass, density and volume flow of gases and liquids; maintains operation even with entrained gas of up to 100%