Silverson Laboratory mixers have been sold all over the world to everyone from small start-up companies to larger international brands. These laboratory scale mixers are ideal for routine laboratory work, research and development, QA analysis and small scale production.

Silverson Laboratory mixers are used for a variety of mixing processes from simple liquid/liquid blending, forming emulsions and reducing particle size to more complex mixing applications in emerging industries such as electrically charged film for window tinting and exfoliation of graphite for isolation of graphene.

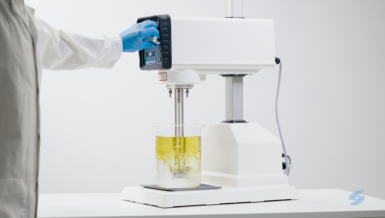

The ‘standard’ L5M-A model is a multipurpose high shear laboratory mixer, which is now available with the body finished in white engineered polymer for increased durability and ease of maintenance. With its integral tachometer, ammeter and programmable timer, the L5M-A offers a level of instrumentation invaluable in applications where process validation and repeatability are required.

The advantages high shear mixers offer over simple agitators and stirrers stem from the specially designed rotor/stator workhead. It is the high speed rotation of the centrifugal type rotor which draws materials into the workhead. Once the materials enter the workhead they are subjected to intense mechanical and hydraulic shear in the precision engineered gap between the rotor and stator screen. Centrifugal force drives the material out through the holes in the stator and back into the mix, while the rotation of the rotor continues to draw fresh material into the workhead, setting up a circulatory pattern of mixing.

As such, Silverson High Shear mixers can be used for many mixing tasks with their versatility increased further by the range of easily interchangeable workheads and screens available for each machine. In a video recently released on their YouTube channel, Silverson explains and demonstrates the uses and results of the most common workheads and screens in their range. A Silverson mixer can be used in place of several pieces of mixing equipment, with changing from one head or screen to another a quick and simple process.

The Emulsor screens main use and function is the preparation of all emulsions. The perforations in the stator help to achieve a uniform globule size and a fine, stable emulsion. The Emulsor Screens are available in either fine or medium which is the standard. These screens are ideal for liquid/liquid preparations and can be used where there is a different in viscosity between liquids.

These interchangeable workheads are available across the entire Silverson product range. Where some mixer manufacturers specialise in production scale models but have no laboratory scale mixers; others offer high speed laboratory mixers that have no production equivalent. This can make it difficult if not impossible to scale up successfully from the lab to full production. One of the main advantages when choosing a Silverson Laboratory mixer for R&D or pilot scale production is the ability to scale up from the laboratory to full scale production models with ease.

Silverson offers the largest range of capacities from a single manufacturer – from 1ml laboratory units up to some of the largest disintegrator systems on the market – and because all Silverson mixers are manufactured to the same precision engineered tolerances anything you produce in the laboratory can be replicated in production and scalable results are achievable across batch sizes.

Another advantage of choosing a Silverson Laboratory mixer is it can also be used for applications where an In-Line mixer is required. Silverson offers an In-Line mixing assembly for the L5 Series. This assembly converts the L5 mixer to an In-Line mixer/homogeniser with a throughput of approximately 20 litres/minute, increasing the mixer’s versatility further still.

Where higher throughput or a designated In-Line laboratory unit is required, Silverson has designed the Verso, a bench top In-Line mixer which can be supplied with a vessel package to replicate a recirculation process at pilot scale. Some new variants of the Verso were launched last year. One of these is the Verso HV which is designed for processing higher viscosity mixers than the standard Verso model. This variant incorporates the same innovative ‘pumping rotor’ design as the production scale HV In-Line mixers which substantially increases its self-pumping capacity and facilitates easy scale up.

The Verso UHS is an Ultra-Hygienic version of the standard Verso machine, allowing it to be used for stringent applications in the Pharmaceutical and Biotechnology industries as well as Food, Cosmetics and other clean industries.