Global lockdowns decreasing demand caused a steep decline in oil prices by 75% in the first quarter of 2020. This caused a logistical storage crisis for hazardous liquid storage terminal operations worldwide as rising stockpiles of crude threatened to overwhelm storage facilities.

Fast forward to today, while markets are stabilizing, the global liquid storage terminal market is still growing and is projected to reach around $37 billion by 2027. Storage capacity is expected to grow by 8% from 8,310 million barrels (MMbl) in 2020 to 8,971 MMbbl by 2024.

With the increased size and complexity of today’s storage terminals, mitigating risks for employees, assets and facilities is quickly becoming a major focus among terminal operators as incidents can affect the overall supply chain. Terminals are already beset by extensive safety regulatory requirements by the American Petroleum Institute and Occupational Safety and Health Administration worldwide as well as the Pipeline and Hazardous Materials Safety Administration in North America to name a few. The handling and storage of hazardous liquids has always been inherently risky, but the rapid industry growth has forced operators to try to meet increased health, safety, and environmental regulatory compliance without increasing personnel, making it even more important today to ensure terminals are safe as well as operationally efficient.

Of course, this requires a reversal of the traditional industry mindset of maintaining the status quo, which has fostered a skeptical approach to automation and digitalization where risk-averse companies sometimes believe it is too difficult to adopt or are not practical for their day-to-day operations.

This leaves many terminal operations stuck in a cycle of using outdated, unreliable, and inefficient systems to perform some of their most common and critical work — thereby costing millions in unrealized revenue as well as millions in regulatory compliance fines — putting them further behind their peers in terms of profit margin, operational efficiency and workplace safety. But in this age of digitalizing liquid storage equipment, operations and facilities, many of these operators still struggle to meet performance goals because they lack the strategic roadmap to turn these new investments into business success. This points to an industry-wide desire to understand how terminals can achieve operational excellence. Fortunately, there is an answer to this demand.

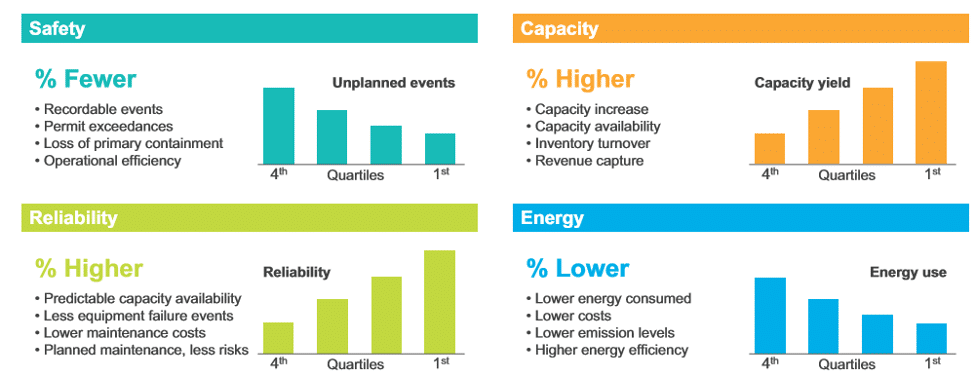

There are 4 main areas where digital technologies can help terminal operators to achieve operational excellence. They are:

- Safety — Remove workers from high-risk activities like climbing tanks for manual readings, avoid product contamination, loss of primary containment, and reducing the number of recordable incidents.

- Capacity — Eliminate time-consuming manual processes that harm asset capacity, inventory turnover, custody losses, terminal throughput, and revenue capture.

- Reliability — Employ technology to gain predictable capacity availability, lower maintenance cost, reduce risk due to equipment failure events.

- Energy — Use technology to become more sustainable by lowering energy usage, reducing emission levels, and reducing overall energy cost.

Sources: Emerson commissioned independent benchmarking data sources to analyze and determine Top Quartile metrics.

There are best practices that terminal operators should follow when implementing a digital strategy in order to maximize their return on investment. Top performing terminals are those with a cross-functional integration of digital technologies, software, services, and expertise that optimize their asset utilization while maximizing revenue.

A successful path to digital transformation starts with a clear business case in an area with potential for improvement. Then, leverage industry and technology experts to identify proven methodologies of improvement. Finally, ensuring the investment considers organizational readiness and connectivity to company culture. In response to industry demand for clear guidance on facilitating digital transformation, Emerson developed a “Digital Transformation Roadmap” to help companies develop and execute a tailored digital transformation plan to ultimately achieve top-quartile performance driven by operational excellence.

The roadmap consists of two primary focus areas: impact domains and enabling domains. Impact domains cover capabilities and performance relative to industry benchmarks. Enabling domains to focus on capabilities in organizational effectiveness, systems, and data integration. Following this proven approach allows terminal operators to have a clear starting point to realize quick wins and maximize their ROI.

As mentioned earlier, many companies are risk-averse and skeptical of the cost and complexity to implement an automation and digitalization strategy. Cost and complexity are always a concern, even in traditional projects. Emerson understands that so we engage with customers in the early stages to help them understand the pros and cons of using digital technologies, but more importantly, the cost of not using digital technologies. We also help them to identify how to start the journey to avoid complexity and cost over-runs using our Project Certainty methodology. This methodology helps customers to ensure success in project implementation and management by eliminating cost, reducing complexity, and accommodating late changes.

A successful digitalization project is more than just technology implementation. It also includes a change in mindsets, as well as a workforce that is well trained to operate in a highly digitalized environment. To be successful, customers must commit to preparing their people and fostering behaviors to fundamentally change their business process. Emerson supports this process by providing the evaluation and the required training to the current and next-generation workforce to become familiar and confident with new technology and processes.

Additionally, Emerson believes in human-centered design in our products and software and, is committed to developing technology that is easier to implement, operate, and maintain.

Learn more about the specific technologies and solutions for achieving terminal operational excellence with these additional technical resources:

- Download Emerson’s Terminal Operations white paper

- Listen to Emerson’s podcast series that highlights some of the technologies that can help terminal operations improve safety, environmental compliance, overall operational efficiencies.