The product starts with about 2 meter long glass tubes that are fed into a machine that heats, deformes and cuts these tubes into induvidual bottles.

The flames that heat the glass are created by mixing a fuel with oxygen. Fuels can be hydrogen, propane, natural gas, etc. Sometimes air is added to lower the temperature.

The goal in this process is uniform and consistent flames, which require extremely accurate and precise gas metering independent from changes in temperature and supply line pressures.

Challenge

A flame is a chemical reaction, and it is the number of molecules that determines the process. So the number of molecules or the mass of the gases must be controlled. In this way, the flame is no longer affected by pressure and temperature variations.

Since the quality of the glass tubes can fluctuate, the flame must be adjusted to the quality of the incoming glass. Some companies even use visual regonition system to measure small changes in the glass tubes and adjust the flames to get the best results

Solution

The MEMS technology used in modern mass flow controllers offers fast response times. Plug & play functionality without warm-up phases improves user productivity.

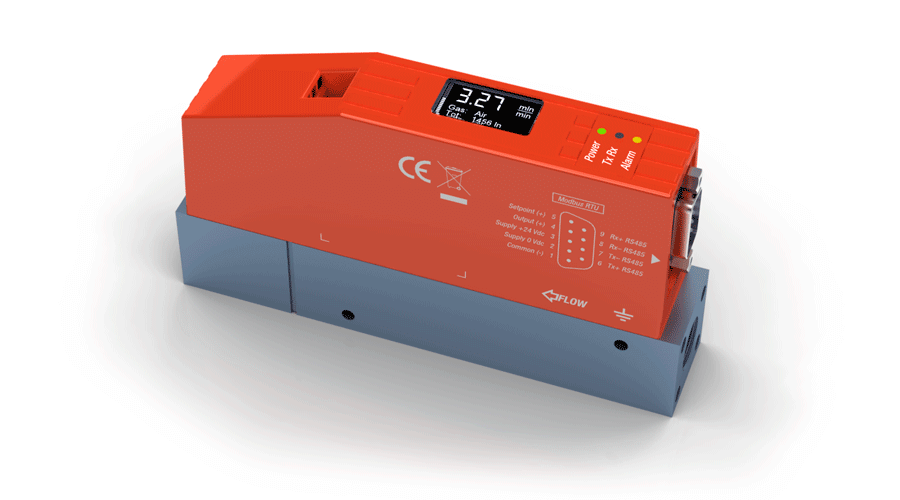

Vögtlin mass flow controllers compensate for changes in ambient or gas temperature through automatic temperature compensation. As a result, changing environmental factors such as air pressure and temperature no longer affect critical flames. This greatly improves repeatability. The MEMS technology ensures long-term stability without deviations under the condition of a clean and dry gas supply. No need to re-certify the units evey year and you get the same repeatable result run after run.

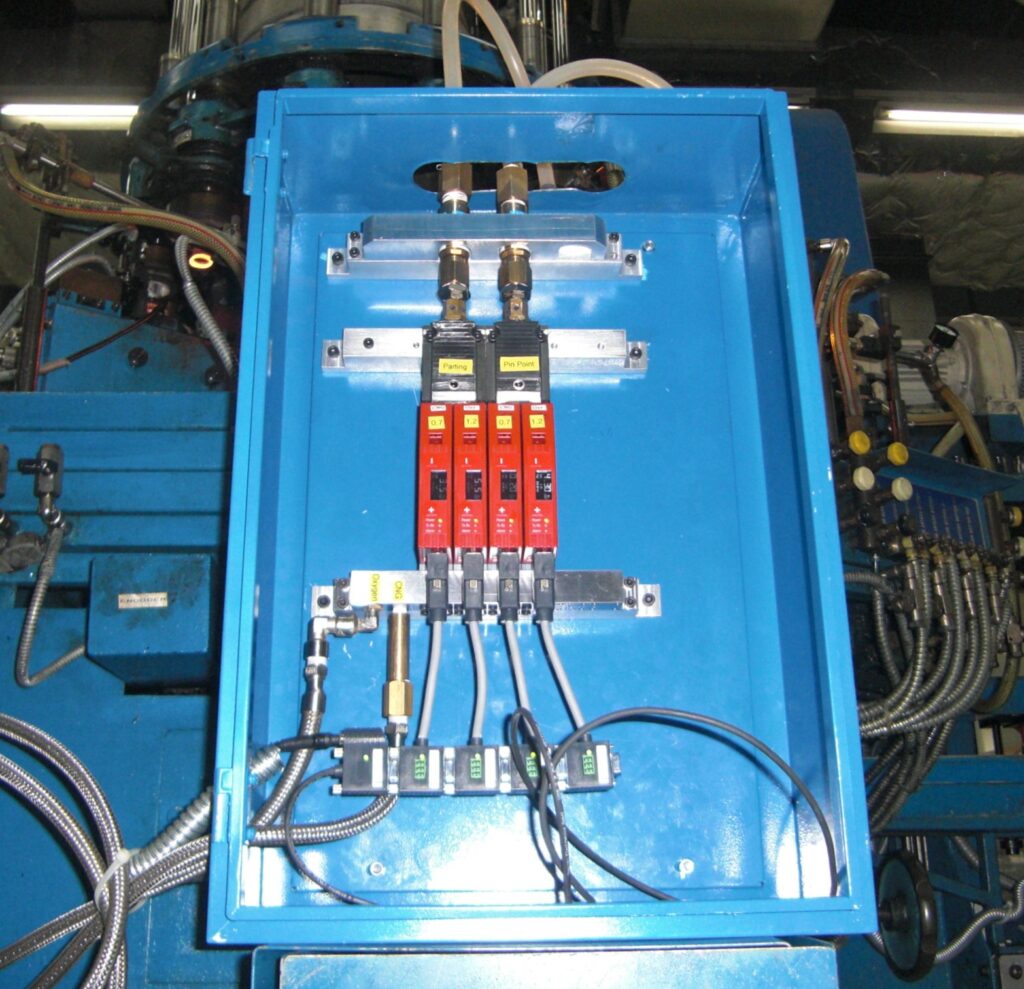

Simple assemblies where a number of Mass flow controllers are built as one block, with O2 and one fuel inlet make it simple and cost effective to install the system with a minimum number of leak points.

Other benefits of these complete gas supply modules include savings in sourcing loose gas fitting components, less time required for field installation, and easy and precise implementation of complicated gas mixing and distribution processes. The devices can be calibrated for different gases in one unit so that you can switch fuels.

However the main feedback we receive is that the users who implement these flame control systems see a huge yield improvement, consistance in calcium contains, no delamination issues, quick start-up of the machine and repeatability. The mass flow controllers earn themselves back in a very short period of time.

High-precision Thermal Mass Flow Meters & Mass Flow Controllers for Gases

Reliable technology and industry-standard interfaces make the red-y smart series thermal mass flow meters (MFM) and mass flow controllers (MFC) particularly suitable for measurement and control in gas delivery systems and plant engineering applications.