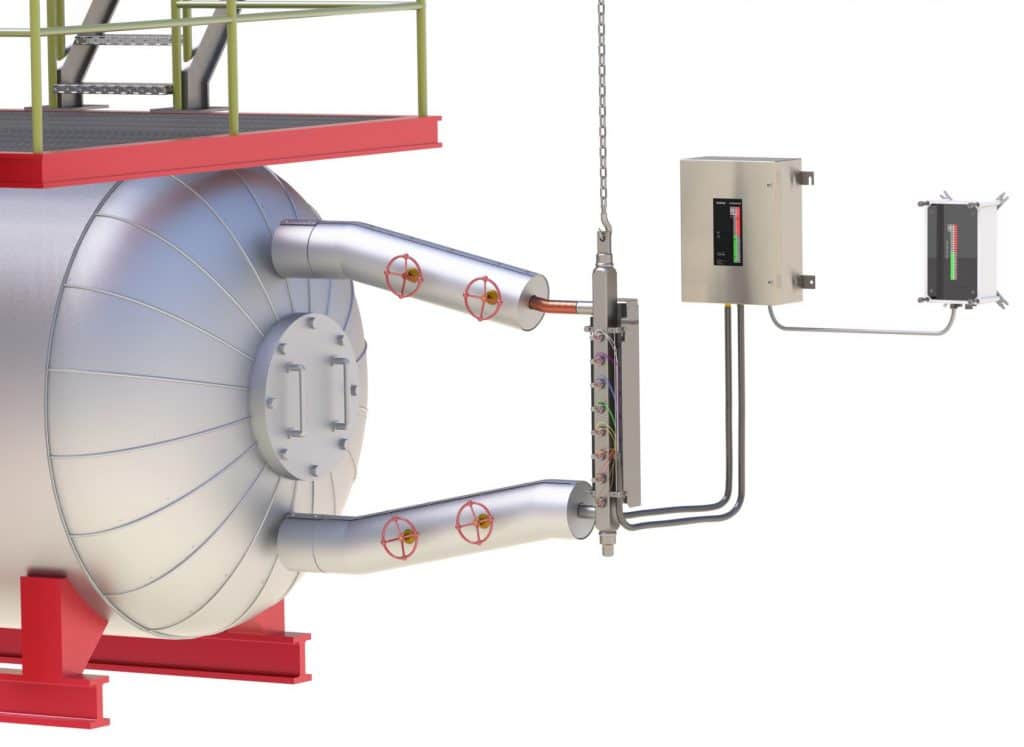

Conductivity probe instruments such as Hydrastep were originally developed as an alternative to sight glasses for steam drums, also referred to as boiler drums or feed drums. Sight glasses, vertical columns attached to the drum with a glass window for level indication, can be difficult to read and originally had no means of monitoring from a remotely positioned control room. Conductivity probe instrumentation provided an alternative to this.

Later improvements to sight glasses included using refraction of a backlight, and then CCTV for remote viewing. Even so, steam water gauging systems based on conductivity probe technology give a clear visual display both locally and remotely and have become the preferred solution for steam drum level indication.

Hydrastep 7

Hydrastep was developed in conjunction with the CEGB, the UK’s Central Electricity Generating Board in the mid-1960s. Referred to as the Hydrastep 7, the system comprised of a vertical water column mounted to the steam drum with a series of probes spaced along the column. These were linked to the electronics mounted within a large floor standing cabinet with a visual display. This replaced an even earlier version, though there is little known detail of this.

Performance trials of the Hydrastep 7 were carried out in the period 1968 to 1972 in several UK power stations. Manufacturing commenced in 1972 with the first installations in 1973. Marketing of Hydrastep into the United States began in 1983 with the first installation in 1984.

Hydrastep 2457

The large cabinet mounted system was superseded by the Hydrastep 2457. This is the earliest model with any known documentation and was manufactured by Schlumberger in Farnborough. This was launched in 1975 as a lower cost and smaller version of the Hydrastep 7. The Hydrastep 2457 had local and remote displays, and relay outputs for level and alarms, but no other output to integrate to a customer’s control or monitoring system.

Hydrastep 2457 features

- 12 electrodes

- Dual redundant drive circuitry (one circuit for odd, and one circuit for even electrodes)

- Red/Green LED local level display

- Red/Green LED remote level display, each LED controlled by an individual signal from the controller

- Relay outputs for trips or alarms

- Fault indication

A later model, the 2457N, had hazardous area certification.

Hydrastep 2467

An output was needed to interface with control systems and so a 4-20mA current output was added to indicate level. This was launched as the Hydrastep 2467 around 1985.

Hydrastep 2467 features

- As per the Hydrastep 2457, with additional 4-20mA output

Both the Hydrastep 2457 and 2467 assumed the lower half of electrodes were in water and the upper half in steam, and could only detect contamination of electrodes in steam. They therefore only needed a single wire connection to the lower electrodes, but a two-wire connection to the upper electrodes. The remote level display LEDs were individually lit by drive signals from the controller, so requiring cables with numerous cores.

Hydrastep 2468

The Hydrastep 2468 was introduced in 1993. This had a number of improvements, one of which was being able to detect contamination of any electrode and so it now required a two-wire connection to all the electrodes. It offers a flexible number of electrodes with several remote display options which are now driven by digital communications, so reducing the cabling requirements.

The Hydrastep 2468 was submitted to Factory Mutual Research (an independent research body) for evaluation. In 1994 Factory Mutual Research produced a report “Reliability Analysis of the Hydrastep Model 2468”. This concluded that the probability of missing a trip situation was 3.2 x 10-9 (for mission time of 1 year, repair time of 24 hours).

- From 8 to 32 electrodes

- Dual redundant drive circuitry (for odd and for even electrodes) with dual power supplies

- Red/Green LED local display

- Red/Green LED remote display

- Digital communications to numerous remote displays

- Up to sixteen relay outputs for trips or alarms

- Fault detection and indication

- Contamination detection for ALL electrodes

During the lifecycle of the Hydrastep the water column design also changed. Original high pressure water column ports took a flanged electrode secured in place by four bolts. This method was superseded in the 1990s and all high pressure and super critical water columns then had inserts welded into the water column body with threaded Swagelok style connections. Low pressure water columns still use the original female threaded connections whereby the electrode is simply screwed into the column.

The electrodes are key to Hydrastep’s proven reliability in the field. The 1990s saw considerable research and development in the electrode. Various materials and bonding methods were trialed. The result is a range of electrodes comprised of exotic metals and ceramics. The key to their success is a highly guarded proprietary brazing method of controlled temperatures and pressure cycles.

Summary

Hydrastep’s history spans almost five decades. Its reliability is second to none, and it is well known and respected, not least within the power industry. While other technologies such as differential pressure or radar are also used for steam drum level measurement, Hydrastep has become the preferred choice for level indication as the display is separate from any monitors and gives an immediate and clear level indication within the control room. Outputs are often used for alarms and trips for emergency shutdown.

The Hydrastep name has been synonymous with conductivity probe level measurement to the extent that even competitor’s equivalent products are often referred to as Hydrastep. It is expected that future developments will mean the Hydrastep name will continue well into the future.