The ingredients should be processed with maximum accuracy, efficiency and resource utilization to consistently offer high quality and safe food, ensuring the greatest possible convenience for customers and consumers.

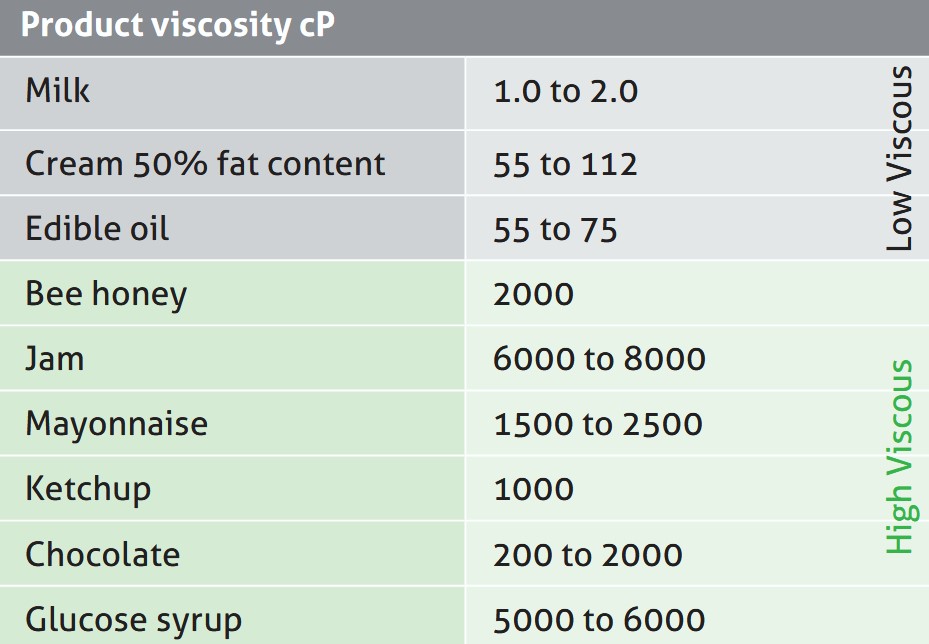

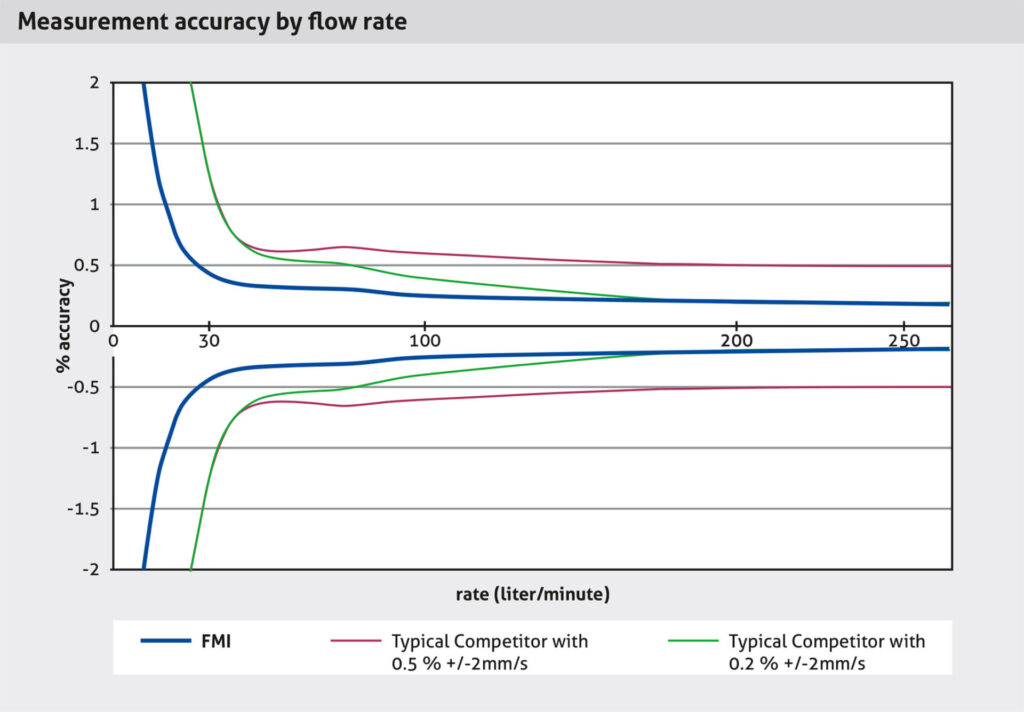

Flowmeters and Level Sensors are important measuring instruments in process control. Due to the special conditions of viscous foods, conventional measuring devices are often not suitable. Such conditions are a low flow rate due to the larger nominal pipe diameters and often a varying viscosity when the process temperature changes. For level control the sticky, adhering consistency of the liquid may cause wrong readings.

This can lead to fluctuations in taste, consistency, product quality or other properties. Eventually product losses due to unprecise control or even plant downtimes due to system errors may occur.

Anderson-Negele as a global specialist for hygienic process instrumentation offers a wide range of sensors which are designed to meet the specific needs of highly viscous products.

Problem Solution for Flow Control

While other flow monitoring technologies like turbines or mass flow meters are less suitable due to mechanical parts in the measuring tube, reduced diameters or substantially higher cost, electromagnetic flow meters offer a precise and cost-effective solution for flow monitoring in the production of viscous food ingredients.

Electromagnetic Flow Sensors

With its measuring accuracy of ±0.2 % ±1 mm/s, Anderson-Negele’s FMI is more precise than other commercially available sensors. A seemingly small difference has a major impact, especially at low flow rates, as is common with highly viscous products. The graph shows the comparison of FMI with competitor products. At a flow rate of 100 l/min, the FMI achieves an accuracy of 0.25%, the comparison products only approx. 0.6% or 0.4%, which is nearly double / tribble. Even at the minimum flow rate of 30 l/min, the FMI still delivers an accuracy of approx. 0.4%, while the reference sensors are about three times worse. This makes the FMI predestined for applications such as food blending, even with high viscosity and low flow rates, as it enables the best possible recipe control.

For monitoring other process steps such as intermediate storage or filling, a slightly lower measuring accuracy is often sufficient. In such applications, the FMQ Flow Meter offers the best price-performance ratio, as the acquisition costs are lower.

Both sensors feature hygienic, FDA, 3A and EHEDG-compliant materials and construction, robust and compact design, process temperatures of up to 165 °C (266 °F) for the remote version, flow ranges of 30…280,000 l/h with nominal diameter from DN10 to DN100 (1/2” to 4”) and an operating pressure of 0.1…17 bar / 1.5…246 psi absolute.

Problem Solution for Level Control

For Continuous Level Control the most used sensors work with hydrostatic or with potentiometric measurement. The potentiometric technology is usually more precise and faster in case of smaller balance tanks, process feeding vessels, or pressurized tanks. However, many devices tend to incorrect readings when adhesions of the product stick to the sensor rod.

The NSL-F Potentiometric Continuous Level Sensor is specifically designed to overcome such errors. Using a second, Anderson-Negele specific measuring procedure, the sensor also provides information on the submersion state of the electrode rod. This system analyzes electrical resonance properties to detect adhesions or foam and suppress in the results, and to reliably prevent erroneous measurements.

Correct Point Level Control for viscous media can be crucial to avoid pumps running dry which would cause operations downtimes. Here the NCS Point Level Sensor supplies accurate data so that the vessels can be completely emptied, and then an alarm signal is emitted.

Examples for real case applications with Anderson-Negele solutions

For its Blendtopia brand, Peak Foods develops and produces ingredient concentrates that allow consumers to easily and quickly prepare themselves healthy smoothies. These concentrates are primarily fruit slurries, such as banana or strawberry purees, with a very low water content but a high percentage of fruit chunk. The very high viscosity of up to about 4000 Cp, the very low flow rate of about 5.7 l/min and the low production temperature of 5 – 8 °C were a challenge especially for the flow measurement. However, for evidence of pasteurization, flow control needs to be highly accurate and reliable. Click on the link to discover how the FMI solved their issue.

Friesland Campina produces rice pudding in a continuous process with a defined production volume per hour. Rice is prepared in a dosing tank and, together with pre-heated milk, is fed through a system of heaters and coolers. The production process is precisely adjusted in its duration so that when the rice pudding is ready for filling on end, a precisely specified consistency is achieved.

In the past, the formerly used level sensor often put out the signal “full”, although there was only foam in the container and therefore no more milk was added. The lack of supply led to blockage and repeatedly caused a production standstill. As a result, the entire production volume could no longer be used, and in addition the cleaning and restarting caused the loss of several hours of production time. A test with the Potentiometric level sensor NSL-F proved that it was completely unaffected by the foam and adhesions and always indicates the correct level of the rice milk mixture. Since switching over to the NSL-F, the process has been running smoothly and fully automatic, there was not a single plant downtime in the entire time.

In the production plant of French Cosmetic Specialist Yves Rocher the filling systems for cosmetic creams were previously controlled manually. In order to prevent the filling pump from running dry, the process was stopped for safety reasons at an early stage, leaving important quantities of cream in the tank. This residual product was then disposed of, resulting in a significant loss of value.

With the NCS-L level sensor, the filling process could be automated. Due to its special sensor shape with 18 mm length and its measuring method with an extended measuring range, the NCS-L-12/18 is particularly suitable for low-water, viscous media such as oils, syrups or, in this case, even cosmetic creams. Thanks to its inline integration in the outlet pipe of the filling system, the sensor signals safely and reliably as soon as no more cream comes out of the buffer tank, thus stopping the filling process automatically.