Product: SupaPore XPG

Application: Syrup Filtration

Opportunity: Lower Production Costs

Client: Contract Bottler

Location: Eastern Europe

Sector: Soft Drinks

More Than Just a Filter: Application Knowledge Is Key

Margins can be tight in Soft Drinks production with manufacturers always looking to improve process economics. From the aspect of filtration, these improvements can typically be made through one or more of the following: 1. Reduction in the unit cost of the consumable filters themselves. 2. Introduction of better performing filters that extend capacity. 3. Better equipment utilisation by improving flowrates thereby increasing the number of batches processed per shift. 4. Improvement to the process itself in terms of flowrate optimisation, cartridge regeneration, etc. Often the first port of call for saving money is to try and get a price reduction on individual filters. This is a short-term view that can prevent focus being placed on longer term process improvement and imbed poor process design. In this case study we show how application knowledge has helped to double the lifetime of a syrup filtration system for a contract soft drink manufacturer.

Original Process & Performance

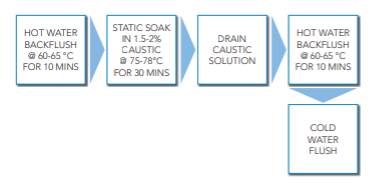

Refined sugar was mixed with hot water at 85°C to approximately 520Bx and then filtered through 3 x 30” competitor 20µm cartridges in batches of 5m3 at a flowrate of approximately 8-10m3 /hr. During production, cold water backflushing was conducted after each 5m3 batch filtered. The filters were regenerated when blockage occurred which was after approximately 30m3 , using the procedure below:

The volume throughput of the filters gradually decreased after each regeneration procedure with a maximum of lifetime of 36 batches being achieved.

New Process & Performance

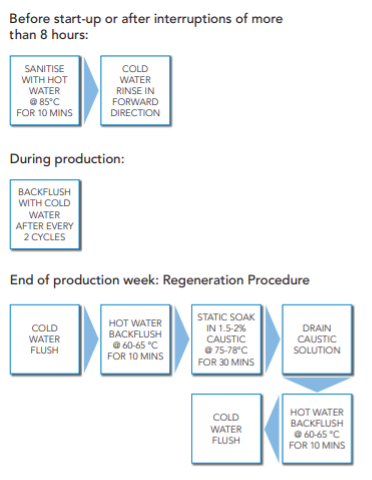

To try and improve overall lifetime of the filtration system, the complete management of the filtration from start-up and (including production breaks) was investigated. At the same time in addition to a change to Amazon SupaPore XPG high dirt holding capacity filters using the same 3 round 30” housing. The modified operating procedures are outlined below:

Conclusion

After implementing the revised procedure along with installation of the Amazon SupaPore XPG filters, the customer realised a doubling in filter lifetime from 36 batches to 72 with a corresponding halving of consumable costs. This highlights the importance of analysing the complete filtration process rather than just focusing on obtaining major improvements by retrofitting different filter types or specifications. The performance of the filter is of course extremely important and can result in process improvements but taking a holistic approach and including operational procedures can bring the greatest rewards.