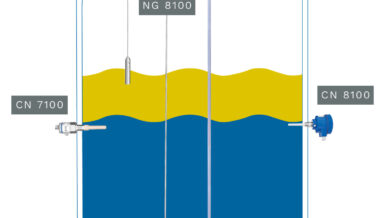

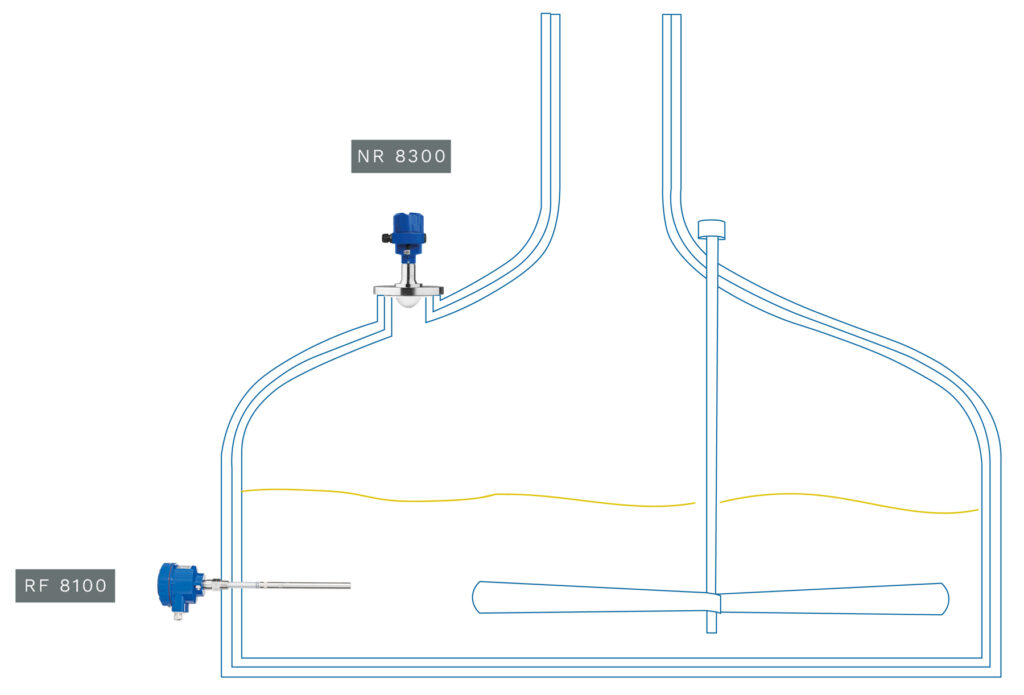

To address these challenges, UWT GmbH offers an optimized sensor system combining non-contact radar technology and capacitive level detection. The NivoRadar® NR 8300 and the RFnivo® RF 8100 ensure hygienic, low-maintenance, and highly accurate operation – even in dynamic process conditions and complex tank geometries.

Robust solution for demanding liquid applications

The 80 GHz radar sensors in the NivoRadar® 8000 series are designed for demanding liquid applications across various industries, including food and beverage, pharmaceuticals, chemicals, water and wastewater management, energy, steel, as well as environmental and recycling technology.

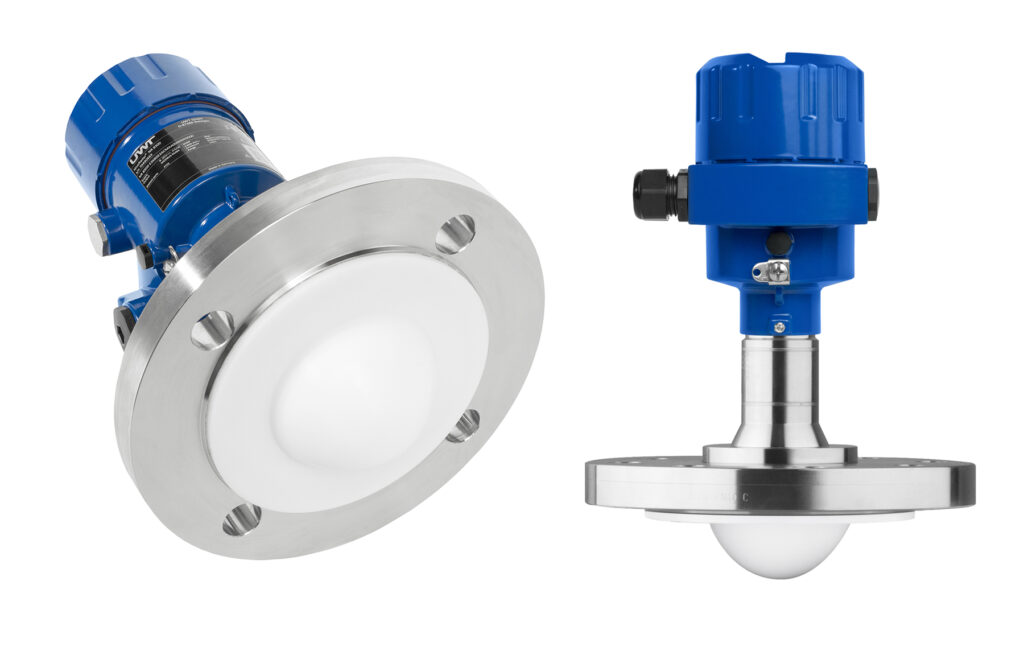

In this application, the NivoRadar® NR 8300 features a fully encapsulated PTFE antenna, chemically resistant wetted materials, and a narrow 3° beam angle ensuring reliable measurement despite steam, agitation, internal obstructions, or foam – all without contact. Commissioning is fast and straightforward using the UWT LevelApp, PACTware, or the optionally available display.

Key benefits at a glance:

- 80 GHz radar technology for precise measurement under real process conditions

- Foam, condensate, and agitator compensation for stable signals

- PTFE-encapsulated antenna and chemically resistant materials

- Focused beam angle (3°) for accurate results – even in narrow tanks

- Process temperatures up to +200 °C (392 °F), process pressure up to 25 bar (363 psi)

- Certified according to SIL 2/3, optionally available with intrinsically safe power supply

- Maintenance-free, durable, and suitable for hygienic processes

- Easy commissioning via UWT LevelApp, PACTware, or optional display

Point level detection with added safety: RFnivo® RF 8100

To ensure safe and proper level control, the capacitive point level sensor RFnivo® RF 8100 – rod version – is used to monitor the minimum fill level in the mash tun. Thanks to its side-mounted installation just above the agitator paddle, it guarantees that there is always enough medium in the tank to prevent the paddle from running dry.

The sensor is highly suitable for hygienically demanding liquid applications, pastes, foams, and sludges, providing reliable switching signals even with build-up or mechanical stress within the tank. The integrated Active Shield technology offers extra protection against false triggering caused by deposits on the probe.

Product-specific features:

• No calibration required and insensitive to build-up

• Robust design, suitable even for use with agitators inside the tank

• Media-contacting materials chemically resistant (PFA, PEEK, FFKM, 316L)

• Pressure-resistant housing, process-safe up to +200 °C / +392 °F and 35 bar / 507.6 psi

• Integrated display with operating menu, digitally programmable

• Various versions available (rod or rope), flexible installation (top, side, angled)

Combining the NR 8300 radar sensor with the RF 8100 capacitive level switch, UWT offers a reliable solution for continuous level and point level detection in the brewhouse. These sensors maximize plant availability, reduce maintenance, and ensure consistently high product quality – even under tough process conditions. Stable level monitoring in the mash tun is fundamental for smooth downstream processes, such as in the lauter tun or wort kettle.