These valves, featuring in-line serviceability and exceptional total life cycle valve, are installed at critical industrial facilities around the world, from power plants to oil refineries, chemical plants, fertilizer plants, LNG compression stations, pulp and paper mills.

One of the value-added features of working with Conval is the company’s robust problem-solving R&D capability. For example, in the mid-1990s, an Australian power station with a 375MW brown coal-fired boiler was having trouble with another brand of angle type, flow-over feed pump recirculation valves. The control velocity trim was limiting mass flow and causing the feed pumps to overheat.

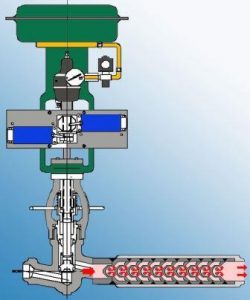

Studying what was a complicated application, the Conval R&D team came up with a flow of 45kg per second using Clampseal globe valves equipped with custom-engineered Whisperjets. Installation took about a week, because the installers had to do some clever re-piping of the pneumatic lines and solenoids to achieve the correct operation. Today, the combination Clampseal / Whisperjet valves are still operating after about 25 years of service. The valves are regarded as excellent, reliable products in what all agreed was a difficult installation.