Challenge:

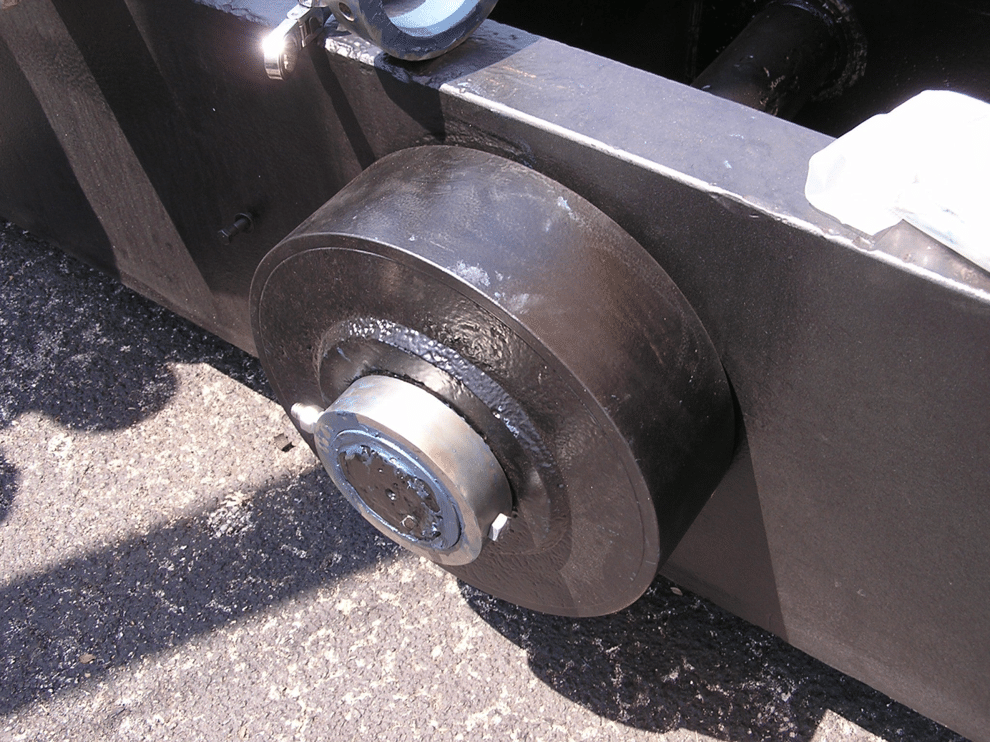

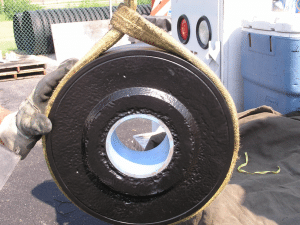

The end-user was having issues in the flood control gates in their district because the flood control gate rollers were seizing. When inspected, the bearings had seized causing irregular wear leading to flattened areas of the roller.

This meant the rollers needed to be resurfaced during maintenance cycles.

The end-user had tried greased bronze, graphite plugged bronze, and phenolic laminate bearings and none of them were suitable in this application. Many of the gate stations operate in remote and often unmanned locations where regular greasing is difficult so the end-user needed a bearing material that was more reliable, required less maintenance, and was able to operate grease-free.

Solution:

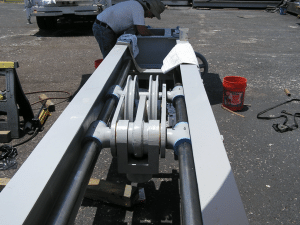

The first visit to the end-user was in March 2004 by Thordon’s authorized distributor in Florida, Coppedge Marine & Industrial. In their initial investigation, the end-user expressed concern over the load and compression on the bearing material as it would be operating under pressures of 31 MPa (4500 psi) in dynamic situations and 41 MPa (6000 psi) in static situations. With this in mind, the distributor proposed ThorPlas-Blue bearings, as 41 MPa (6000 psi) is within Thordon’s properties for the material and could stand up to the design pressures for this application. ThorPlas-Blue’s self-lubricating properties meant that the existing greasing system could be eliminated. An additional benefit to the end-user was the ease with which ThorPlas-Blue can be machined and installed.

Result:

ThorPlas-Blue bearings were first installed in this critical flood control gate application in 2006. The regular maintenance and repair cycle for these gates is ten years and every gate that has been brought in for maintenance since the first installation had new ThorPlas-Blue bearings installed replacing the original ones. When the gates that were running with ThorPlas-Blue for over ten years were brought in for inspection during their regular maintenance cycle, they showed that the bearing material had little to no wear, and as such the replacement was precautionary, not necessary. The wheel housings also did not need to be resurfaced because the bearings were running smoothly and the gates did not seize. Based on the success of this application, other water districts within the state of Florida, as well as water districts in other states, are now specifying ThorPlas-Blue bearings for flood gates in their jurisdiction.

The end-user has experienced the following benefits by using ThorPlas-Blue bearings in this application:

- Cost Savings Immediate capital costs were saved by eliminating the grease delivery system. The end-user experiences additional operational savings as they no longer have to purchase grease (food grade or otherwise).

- Long-Wear Life 10+ years of bushing life expectancy means reduced maintenance time and costs. No seized gate rollers during critical gate operation.

- Environmentally Safe There is zero pollution into Florida’s rivers and streams as no grease is used to lubricate the bearings, as the bearings are self-lubricated.