Background

In the oil and gas industry, removing impurities from petroleum fuels leads to cleaner emissions and improved downstream processing.

For example, hydrodesulfurization (HDS) and hydrodenitrogenation (HDN) are chemical processes that use catalysts to remove sulfur and nitrogen impurities. New legislation such as IMO 2020 for marine fuels and Tier 3 for automotive fuels requires substantial reductions of sulfur and nitrogen to reduce their environmental impact.

ILS-Integrated Lab Solutions, GmbH, is a world leader in providing medium and high-throughput refinery testing units. They have extensive experience with HDS and HDN applications where exceptionally low flow rates and high pressures are needed to provide true trickle- and plug-flow to reactors to reach high sulfur conversion levels.

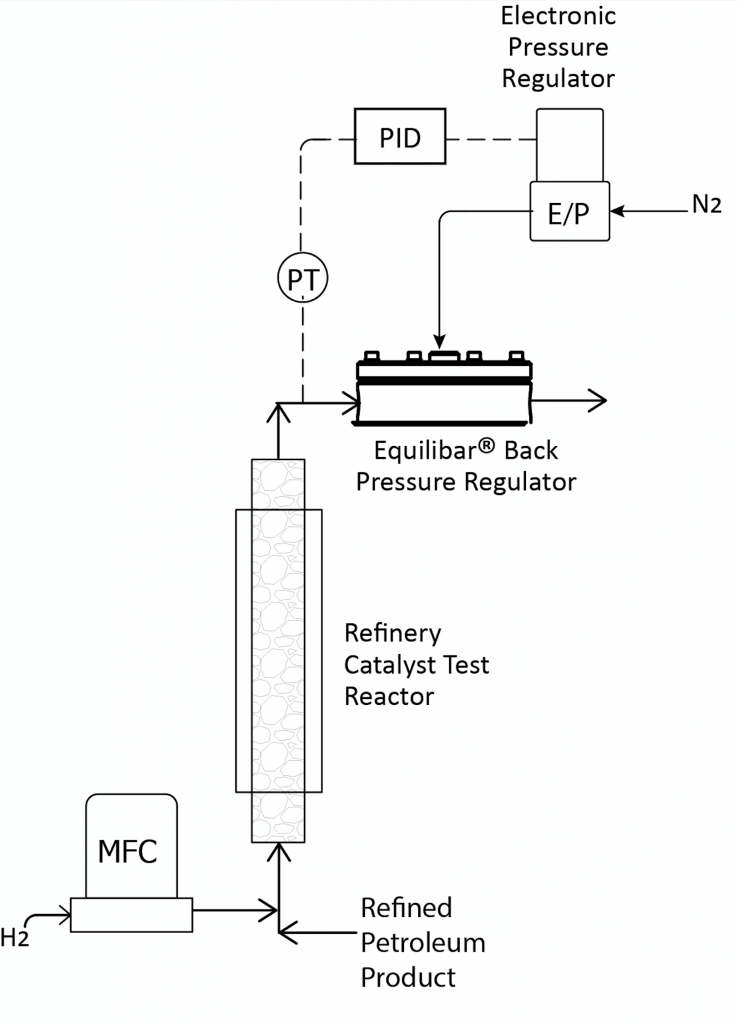

For their recent HDS and HDN applications, ILS worked with Equilibar, an engineering and manufacturing company that specializes in challenging fluid control applications. To provide superior control for this complex situation, Equilibar engineers recommended a radically different type of dome-loaded back pressure regulator that uses a diaphragm covering a field of parallel orifices. As fluids flow through the unit, the diaphragm lifts off the orifices to release pressure.

Benefits of direct-sealing diaphragm valves

Dome-loaded diaphragm technology is uniquely well suited for applications involving two-phase flow because it uses a direct sealing diaphragm over multiple orifices to control the pressure drop. The valve action is not provided by the movement of a tapered stem, but by the close proximity of the diaphragm and the orifice plate. The supple diaphragm can vary its proximity to the orifice nearly instantaneously to adjust to the varying valve coefficient requirements of the various phases.

A further benefit is provided by the unique multiple orifice design. Even if one orifice is totally flooded by the denser liquid, volumetric flow control can still be maintained so long as some of the orifices are still predominantly in the gas phase.

In the ILS system, the ability to manage two-phase backpressure control means that high pressure gas-liquid separators are no longer necessary. This is particularly helpful in units handling heavy feedstocks such as Vacuum Gas Oil (VGO) or Bitumen where the process has to be heated to temperatures above 150°C. ILS engineers find the Equilibar controller to be insensitive to blockage by particles and useful in preventing the formation of aerosols, which are hard to crash out.

Additional benefits are the compact size and gas dome-loading of the controllers. These qualities allow them to be easily placed into ovens and then operated remotely through pilot lines run to the dome reference port. This setup is an improvement over that which is required for traditional style valves where the control valve is closely tied to the needle actuator. When using traditional valves, engineers must often install separate trace heating to avoid significant heat-loss because those valves cannot be placed into ovens. Finally, the superior turndown of the Equilibar BPC provides researchers with a much broader pressure-flow testing envelope over which they can test catalysts.

“The design of these devices is unique,” said Dr. Anton Nagy, founder of ILS. “They have a definite advantage for two-phase flow and catalysis.”

About ILS

ILS-Integrated Lab Solutions, GmbH, is a world leader in providing medium and high-throughput refinery testing units as well as other chemical R&D services in Berlin, Germany. Contact them at info@integratedlabsolutions.com / https://www.integratedlabsolutions.com/