A key area that Eni wanted to focus on was emissions from valves, and they had already made great strides in their effort to reduce fugitive emissions. In 2019 alone, they saw their upstream methane fugitive emissions reduced by 44% from the year before. Once they were able to identify that the emissions were coming from the valves installed at one of their largest facilities in Italy, they decided they needed to look into upgrading their valve technology. After careful research they selected the Dilating Disk™ technology to be installed in several control valve applications. These new valves replaced Fisher globe valves and Fisher V-ball valves, with the applications varying in size, fluid, temperature, and pressure.

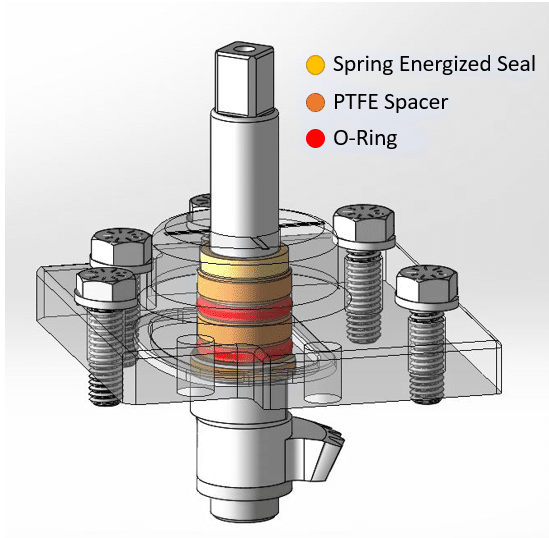

Created with aerospace design principles in mind, the Dilating Disk™ records a methane leakage rate of only 2 parts-per-million (PPM), compared to around 500ppm in conventional globe valves. This makes the Dilating Disk™ the ideal solution to dramatically reduce fugitive emissions through a simple plug and play control valve upgrade. To fix Eni’s fugitive emissions problem, the team at Clarke Valve installed lighter, smaller Dilating Disks to replace the globe valves that were causing leaks. In addition to virtually eliminating fugitive emissions, the Dilating Disk™ requires less torque to open and close, making it more energy efficient when running.

The installation of the valves occurred over a period of 3 days. Once installed, the valves were immediately tested by the control room to ensure that the valves were calibrated correctly.

All of the valves were able to be dropped into place with no modifications made to the pipe. The majority of the valves being replaced followed the ISA standard face to face dimensions, which Clarke Valve designs to as a standard. The remaining valves required a custom configuration, which Clarke designed in order for the valve to fit into the existing pipe.

All of these valves have been installed since February of 2020, and have been operating smoothly without any issues.

Currently, performance data is being analyzed and the valves are all running within their operating range with no concerns.

“The advantages provided by Clarke Valves are indisputable”

Facilities and Production R&D Project Manager at Eni

Clarke Valve is the creator of the proprietary control valve technology used in their revolutionary Dilating Disk™. The Dilating Disk™ design allows it to seamlessly replace globe valves, with no disruption or switching costs. The unique design has been proven to reduce cost, maintenance, and fugitive emissions in the Oil & Gas industry.

For more information on Clarke Valve and their mission to eliminate fugitive emissions from control valves, click here.