As the United States and many other countries fight to crack down on their environmental footprints to reach Net Zero 2050, many new regulations could be put into place. True climate progress will require all sectors to play a role, and although industries worldwide will be impacted while navigating these new policies, the Oil & Gas industry is one of the major sectors that could be very heavily obstructed by future regulations and rules.

During CERAWEEK in March of 2021, philanthropist and investor Bill Gates spoke about energy transition and the cost of switching to cleaner technologies that emit fewer greenhouse gases. Though there are several clean technologies available for implementation, they are not always easily accessible or affordable, and many facilities cannot afford the downtime of this transition on top of the technology costs. This “Green Premium”, or additional cost that is found on clean technology, is one of the major bottlenecks in the Oil and Gas industry’s path to climate change.

According to research by DNV GL, this sector is expected to boost future energy system investments this year, as many of the key players seek to make a sustainable transformation for the coming years. While Oil and Gas is largely criticized for greenhouse gas emissions, many of the current technology options to lower the economic impact of the industry are very costly. To lower these premiums and make clean technology available across the Oil and Gas sector by 2050, current technology is in need of innovation.

Innovation often comes with an added risk or cost, but these costs are often short-term, especially when long-term benefits are generated. Companies and investors who take these risks are fulfilling their duties in the effort to make climate progress, because eliminating the Green Premium is essential to the adoption of environmentally friendly technology.

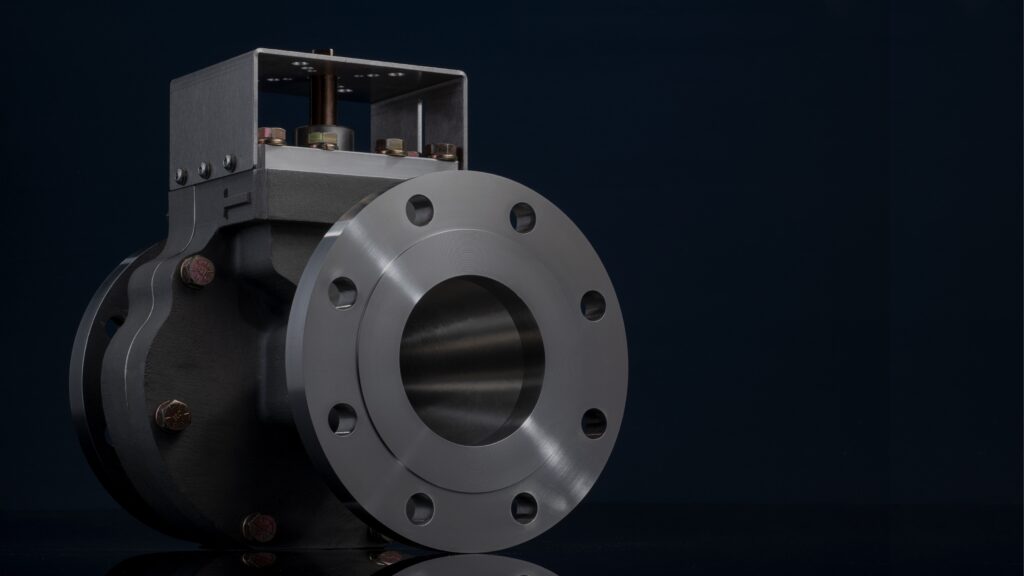

The U.S. Environmental Protection Agency states that 60% of all industry-based fugitive emissions derive from valves, and that up to 80% of this leakage is found in the stem-seal interface alone. To better serve partners and customers in the Oil and Gas industry while fulfilling the company’s goals to play a role in climate progress, Clarke Valve engineered the Dilating Disk™ to reduce emissions in the stem-seal interface with a patented series of stem seals. The unique, near-zero leakage technology of Clarke Valve control valves is available for as low as 50% of the price of competitors’ “low-emissions” control valves. Clarke Valves are API 641 and ISO 15848 certified to reduce emissions up to 98% and have been tested in the field to prove that emissions are typically eliminated entirely to 0ppm.

In addition to these benefits, the Dilating Disk™ also conforms to the face-to-face dimensions for globe valves defined by the ISA 75.08 and ASME B16.10 standards. This allows the valve to seamlessly fit into existing lines with no modifications needed, eliminating downtime and loss of productivity. With this additional benefit, Oil and Gas refineries, as well as any other facility installing the product, are able to lower their environmental footprint without hefty switching costs or production delays. Though Clarke Valve may not be able to eliminate the Green Premium across all sectors, providing green, cost-effective technology to the Oil and Gas sector is a key step on the journey to a more sustainable and clean industry.