Due to the constant low viscosity of the media, pump capacities can be reduced and damage caused by solidifying solids to the pipeline or the valves can be avoided.

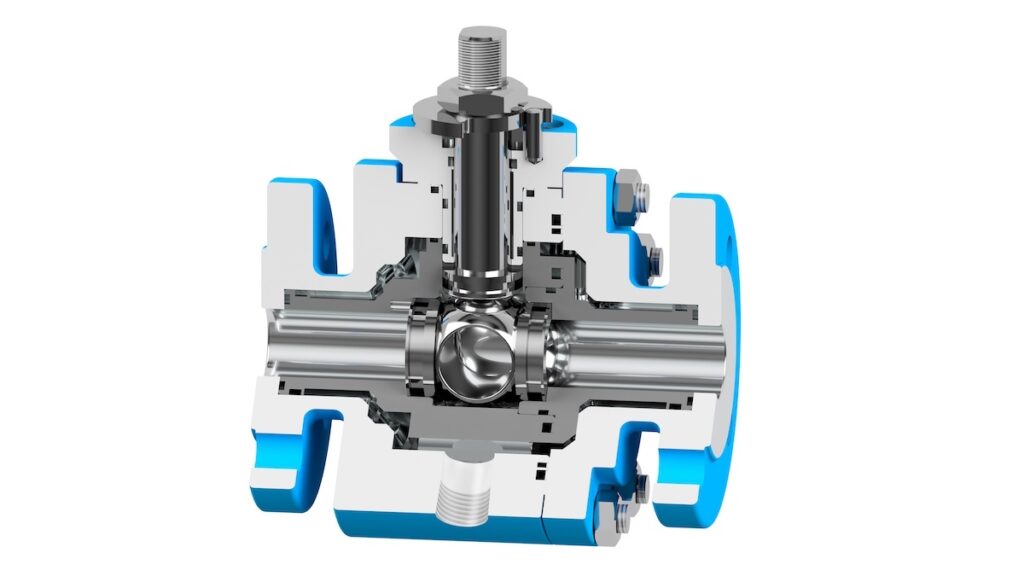

Traditionally, double jackets are welded to the outside of the valve body to heat the media. The new ball valve design from Hartmann Valves integrates the heating jacket into the ball valve body and eliminating the need for welding double jackets. The integrated heating jacket reduces the distance between the heating medium and the process medium, which significantly improves heat transfer.

The purely metallic sealing ensures that even if solids are contained in the medium (such as sulfur cement in the case of liquid sulfur), the essential seals are not damaged or destroyed. The new design provides a space-saving and easy-to-install alternative to the traditional heating jacket system.