Anderson-Negele now offers a solution: thanks to a strategic partnership with its distribution network, the hygienic sensor specialist enables same-day delivery of magnetic-inductive flowmeters throughout Europe for orders placed before noon.

An extensive range of flanges means that even devices from other manufacturers can be replaced quickly and with minimal effort. This new service ensures that your operations stay up and running, minimizing costly interruptions and keeping your processes efficient

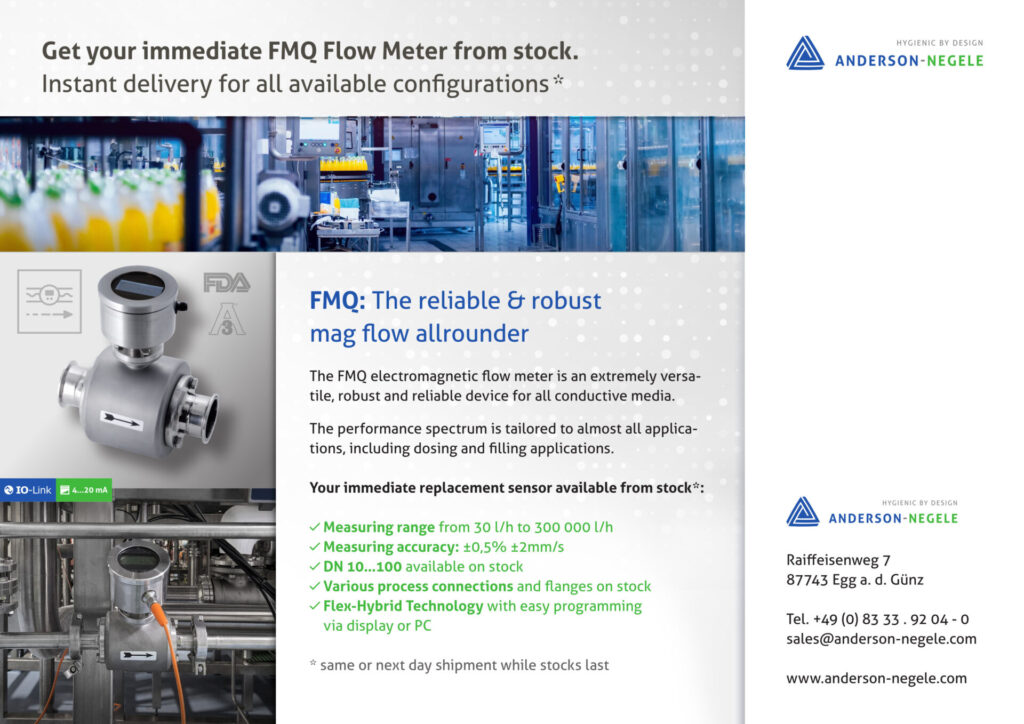

It has proven itself thousands of times over in a variety of applications in the food, beverage, and pharmaceutical industry as an extremely robust and compact all-rounder: the magnetic-inductive flow meter FMQ offers a measuring range of 30 to 280,000 l/h for nine pipe diameters from DN10 to DN100. This makes it ideal for dosing and filling applications involving liquids, slurries and pastes with a minimum conductivity of > 5 μS/cm. These include milk, beer, cream, yoghurt, but also CIP media.

The FMQ is also the device of choice for highly viscous products such as chocolate sauce, honey or jam, as well as products with particles such as berries, nuts or other ingredients. With a measuring accuracy of up to ±0.5 % ±2 mm/s and a process temperature of 0 to 165 °C, the performance spectrum is tailored to meet the needs of almost all applications.

It has everything you really need

With a very competitive list price, the FMQ is economically very attractive and achieves a very favorable lifetime cost balance due to its long service life. However, the device is not stingy when it comes to performance:

- Extremely compact: the minimal size of the measuring body and electronics enables simple, vibration-resistant integration into almost all applications

- Extremely robust: all components are made entirely of stainless steel, and the magnetic field coils of the measuring system are encapsulated. This guarantees permanently reliable, precise measurement results even in very harsh environments with strong vibrations or pressure surges

- Extremely reliable: Completely protected against moisture, corrosion and vibrations; vacuum-proof measuring tube lining made of high-quality PFA; process temperature of up to 165°C for the remote version, CIP-capable, piggable

- Always correct: Automatic signal processing ensures correct measurement values even when changing media (e.g. milk/CIP cleaner)

- Very easy to start up and use: User-friendly, rotatable display with optical buttons, no need to open the housing, no mechanical buttons, for quick and easy programming

- Manufacturer-independent process connection: standard aseptic flange according to DIN 11864, O-ring, without hygiene-sensitive surface seal, pipe standard DN10…DN100

- Standing out: Optionally as a remote version with separate electronics up to 10 m

- Versatile: IO-Link and 4…20 mA communication in one unit simplifies commissioning and operation

The all-rounder now ships on the day of order

In cooperation with a distribution partner, Anderson-Negele now offers same-day shipping within Europe for its FMQ in many available configurations. In addition, a wide variety of flanges and process connections can be obtained from stock, enabling quick and easy installation of the device in a variety of measuring points, even if devices from other manufacturers were previously installed.

This service is designed to support food and beverage producers that cannot afford to keep a reserve stock of all the sensors they install, to improve their response time in an emergency.