Doing things differently, better, and more cost-effectively for our customers, has been our design philosophy since Titan Enterprises launched its first flowmeter sensor in 1981. With market-leading innovation, Titan’s liquid flow measuring products and technology are industry proven on a global scale for use within a wide range of process and industrial applications.

With both standard flow measurement devices and OEM modifications or unique designs to accommodate customer specific applications, Titan’s flexibility and close, long-term customer partnerships have resulted in many OEM manufacturers specifying our products in equipment that will remain in production for many years.

To facilitate a customer’s decision-making process to determine the most suitable flowmeter for their application, the following comparison table highlights the key features of Titan Enterprises’ Turbine, Oval Gear and Ultrasonic flow meters. The more detailed technical specifications of these flow measuring devices can be found on Titan’s website, where a comparison chart of each flowmeter type can also be viewed.

| Flow Meter Type | Mini Turbine Flowmeters “Best value” | Oval Gear Flowmeters “Most durable” |

| Technology | Titan’s small turbine flowmeter range use a radial flow principle based on the Pelton wheel technique. The geometry of the turbine and the fluid chamber ensures that the rotational speed of the rotor is proportional to the flow rate through the device. The low friction obtained with sapphire bearings gives these turbines an excellent dynamic flow range and low flow capability, ideal for low viscosity liquids. | Oval Gears work on the principle of near to true positive displacement. They have a low flow capability and controlled rubbing surfaces to reduce friction. Perfect for more viscous fluids, Titan’s oval gear meters have a greater flow range and improved linearity, with higher viscosity liquids. Specially profiled gears are used for viscosities above 1000cSt. |

| Construction | Metallic and non-metallic options for the meter body, including materials that meet NSF-Approval for use in medical, laboratory, food and drink industries. The combination of materials used to construct the turbine flowmeters ensures chemical compatibility and long-term reliability and stability. | Machined in durable materials with options for non-metallic PEEK, stainless steel or aluminium materials. Sensors suitable for hazardous areas are also available. A pair of PEEK toothed oval gears sit at the heart of the meter, one of which contains chemically resistant magnets. The choice of materials permit Titan’s Oval Gear (OG) devices to be used on water-based liquids as well as lubricating fluids that have a higher viscosity. |

| Product Life | Standing Titan apart from our competitors is our 3 or 5-piece bearing assembly. Titan use robust low friction sapphire bearings that give prolonged reliability and long life to the turbine meter itself. In addition, the bearing contact area of Titan’s mini turbines is relatively large, hence bearing loads are much less than other mini turbine bearing systems. | Titan’s oval gears are carbon filled PEEK as this material is mouldable and has excellent low friction properties, very similar to the old industry standard phosphor-bronze bearings. It also has good temperature capabilities and excellent chemical resistance. All of Titan’s gears are precision moulded and then lightly machined to ensure consistency of the bearing surfaces and long-term performance. |

| Performance | The flow chamber of Titan’s turbine flowmeters is specially shaped to induce peripheral vortices around the chamber, reducing fluidic drag at lower flows. Accuracy is at ±1.0 / ±2.0% FSD (for the 800 series mini turbines). Even for larger flows where some of the liquid can bypass the turbine chamber, accuracy is still maintained and the output remains linear. | Because the high ratio between the driving force versus the resistance of the gears to rotate, these OG flowmeters are capable of very low flows and require minimal differential pressure to begin rotating. They are also capable of high flows with excellent accuracy, even with low viscosity liquids. Titan’s OGs give an accuracy from ±0.5% for oil and water flow. By nature, these devices perform better at higher viscosities as the increasing fluid thickness reduces the leakage rate around the gears even further and extends the useful operating range to lower flow rates. |

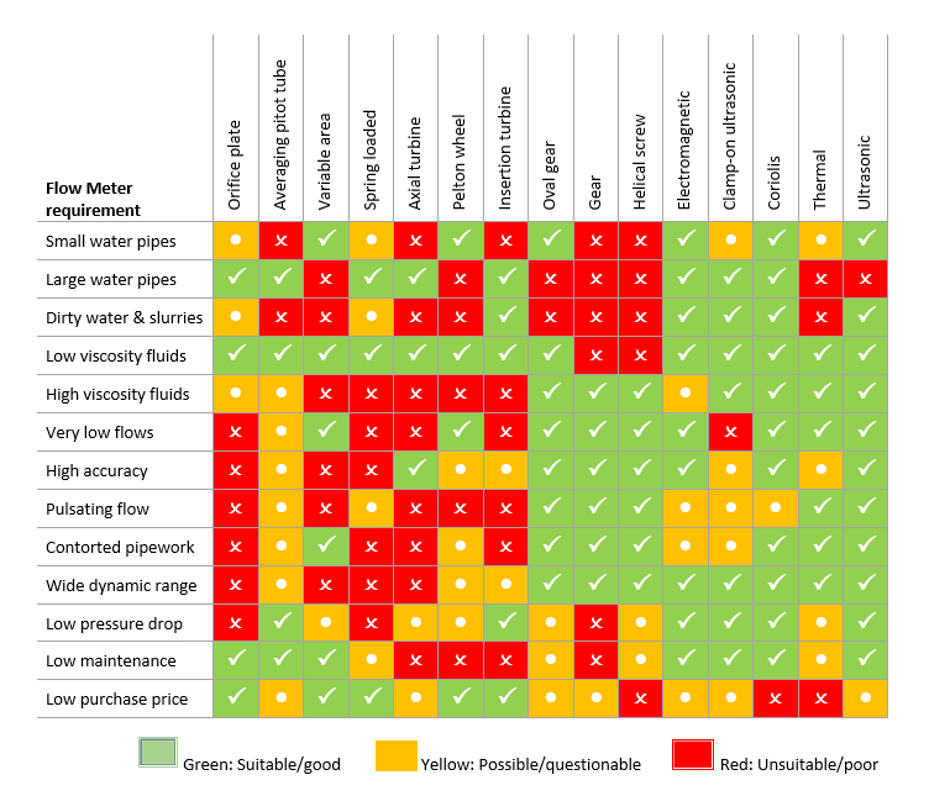

The basic physical techniques that flowmeters work to are well established; it’s the latest technology and materials that are applied which give the wide variety of choices in the market. Titan Enterprises are specialist design and manufacturers of turbine, oval gear and ultrasonic flow measuring devices. However, additional broad groups of flowmeters can be explored further in our technical paper. The following table indicates the suitability of a broader range of flow sensors for a variety of applications.