Challenge

An international chemical company needed a valve solution to meet these extreme conditions. It realized the tough technical requirements being imposed on the valve design was probably going to be outside the scope of the present valve being used, as well as designs from any other severe service valve supplier.

This particular application required isolating the flow of ethylene gas from a discharge cooler. Previously, the chemical company had been using their own design, based on old plug valve features, which made it difficult to seal and isolate in gas applications. Additionally, there was serious concern about the issue of packing leakage.

The life of their valves had been only around 3 months before requiring repair or replacement. The new test valve needed to perform with reliable stroke and dependable shutoff while reducing downtime.

Solution

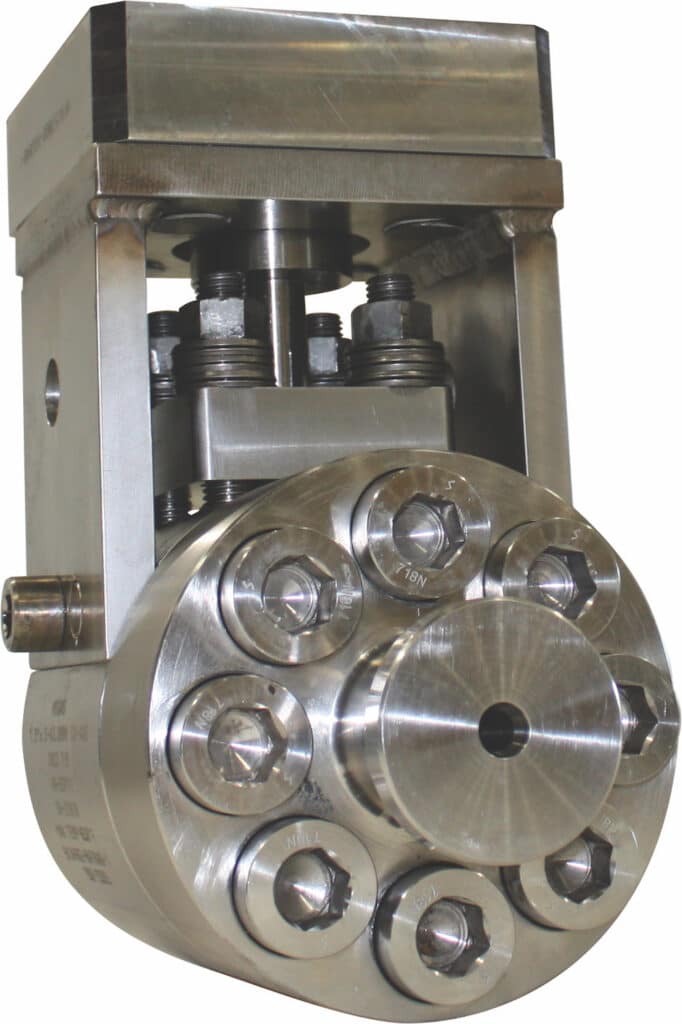

MOGAS provided the expertise, backed with a proven history of valve experience, to become their technical “design partner” in developing and testing an ultrahigh-pressure valve. MOGAS partnered with the customer

for a decade establishing and revising testing practices, improving packing integrity, and making design modifications to reduce cycle torque and to ensure bidirectional ultrahigh-pressure sealing.

Results

MOGAS stayed committed to designing a custom valve model to meet the exact demands of their customer. This new valve passed hydrostatic body testing to 60,000psi, and nitrogen gas and differential pressure hydrostatic seat leakage tests up to 34,000psi.

A year after installation, a new engineer at the plant described the performance of the custom valve as “doing great”, and the company would soon order four more 1-inch valves with electric actuators. Further inquiries have been received for an additional nine (9) 1/2-inch valves, which are in the custom design phase in early 2021.