The valve needed to be tested using helium and was required to provide a bubble tight seal. Since the high-pressure ball valve would be part of the testing system at Michoud, the valve had to meet NASA’s exacting cleaning specifications and pass testing requirements that went beyond the standard API 598 valve test procedure.

Engineers reached out Tom Gosling, CEO of Gosco Valves, who had experience providing valves for NASA and other aerospace companies.

“We recently supplied a 1” valve designed to control liquid oxygen to the rockets. Michoud also has a Gosco 8” ball valve designed for 15,000 psi nitrogen. We know aerospace,” he says.

“We are a company that specializes in ball valves for tough applications. We love a design challenge. I know that our valves can handle the high pressure. It is the helium that adds a layer of complexity. Luckily, we’ve built valves that seal on helium,” says Gosling.

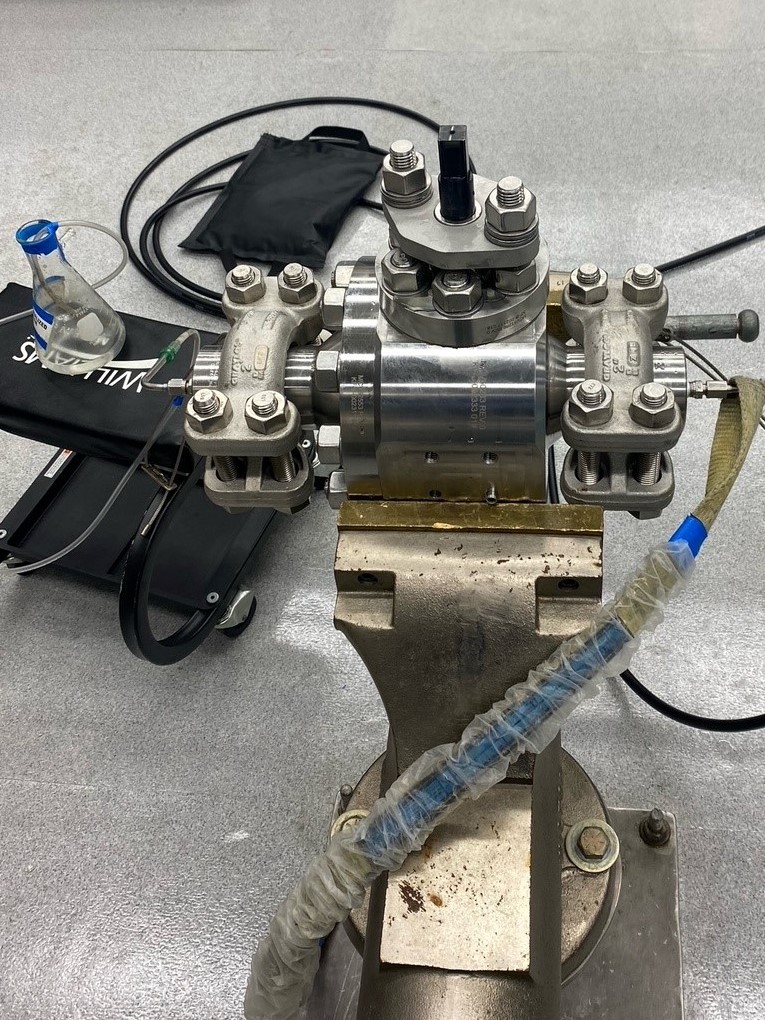

Gosco Valves custom-built a 2500# class fabricated ball valve mounted with a Kinetrol actuator. It easily passed NASA’s stringent cleaning and testing requirements, as witnessed by their inspector.

Tom Gosling, CEO of Gosco Valves, concludes, “The aerospace industry is constantly pushing the limits of what can be done. We’ll do our part by designing valves that help pioneering companies and research facilities achieve those major technological milestones.”