Flashing is a well-known problem in industries that use steam boilers or steam processes. It occurs when the pressure of a fluid passing through a valve is lower than the same substance’s vapour pressure. This causes the fluid to boil – otherwise known as ‘flashing’. It can cause severe erosion and reduce both the operational performance and lifespan of the valve that manages the flow of liquids through the steam process.

While solutions have previously tended to rely on costly extra maintenance and replacing worn-out parts, IMI Critical Engineering has designed a breakthrough engineering solution that prevents the damage in the first place: EroSolve Flashing. This patented solution gives better control over steam processes, making them safer, more efficient, and more reliable.

Customer-centric solution

A dedicated team of engineers at IMI Critical Engineering, led by Project Leader, Jacopo Deglinnocenti, developed the new solution. The solution originated from a problem a manufacturer in the chemical industry was experiencing, where a recurring issue on blow-down valves couldn’t be fixed.

IMI Critical Engineering’s engineers carried out root cause analysis of the problem, which identified flashing issues. Having identified the problem, the team went a step further and decided to apply IMI Critical Engineering’s problem-solving experts to develop a solution. This involved a multi-disciplinary team, working at speed in four separate sprints, allowing them to test assumptions and find the optimal solution.

“Having identified the source of the problem, our engineers were able to use our extensive engineering knowledge and agile methodologies to develop a best-in-class solution,” said Jacopo.

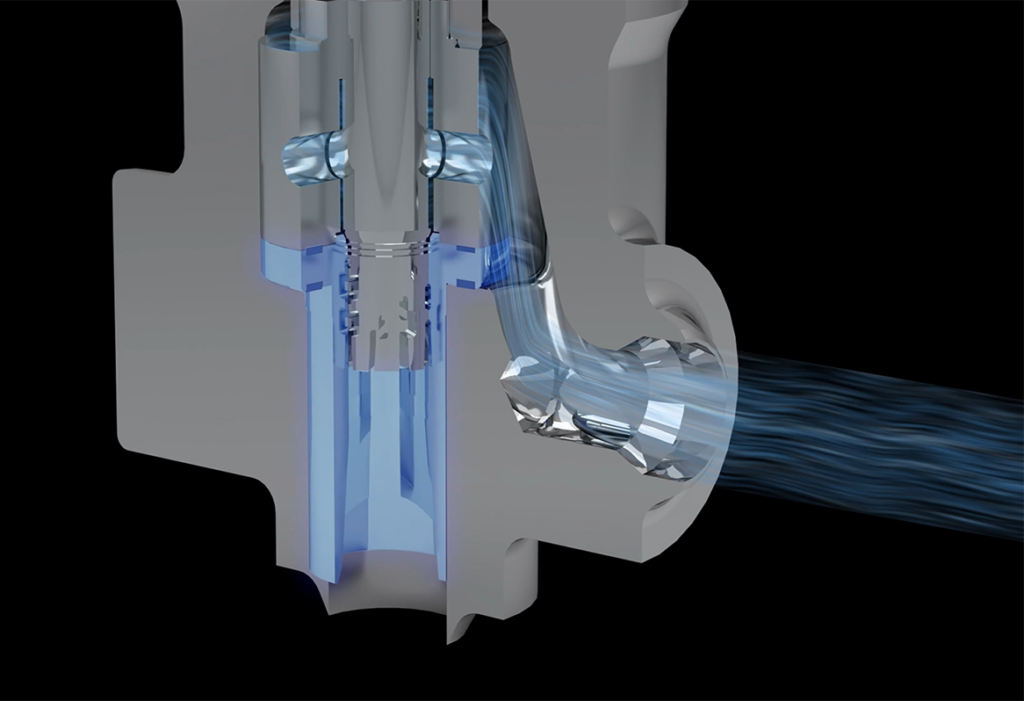

After much design and testing, the EroSolve Flashing solution utilised Angle Valves, as an angle body configuration is the most effective for controlling flashing, as well as these unique features:

- Hardened trim materials are used to increase resistance to erosion

- A new seat design that maintains tightness and prevents leaks

- A multi-part, multi-turn plug design which moves the flashing point away from the most vulnerable parts of the valve trim.

IMI Critical’s EroSolve Flashing is a game-changing solution for flashing problems

Once the team had tested and finalised the design, it was time for testing in the field. “The customer tested several valves in the field,” explains Jacopo, “and after 6 and 12 months, when the valves were checked, no erosion had occurred.”

Once the EroSolve Flashing solution had been successfully proven in operation, the team decided to expand the portfolio. As globe valves are one of the most common valve configurations, a Globe Valve Flashing solution was developed. This drastically improves performance and safety, while allowing the pipe layout to remain the same. This solution involves using a seat basket, which can be in one of three configurations to match operating conditions, to divert the erosion to the seat basket from the valve body.

A simpler design, for less severe operating conditions, was also developed in both angle and globe configurations, providing an alternative for less critical processes.

The EroSolve Flashing solution was designed to solve a problem in the chemical industry, but it has much wider applications and is now being used in the power, oil & gas, and petrochemical sectors. “EroSolve Flashing is just one example of how we are applying breakthrough engineering,” says David Powell-Wiffen, IMI Critical Engineering Growth Hub Director, “to support our customers and develop solutions to resolve their fluid handling problems.”

For more information, please visit our EroSolve Flashing solutions webpage.