The range of 3D printing technologies and materials is continuously expanding. Thermoplastics are among the most commonly used materials – easy to handle, they can be fed into machines as filament, melted, and formed layer by layer. However, in demanding industrial applications, metal remains the material of choice for additively manufactured parts.

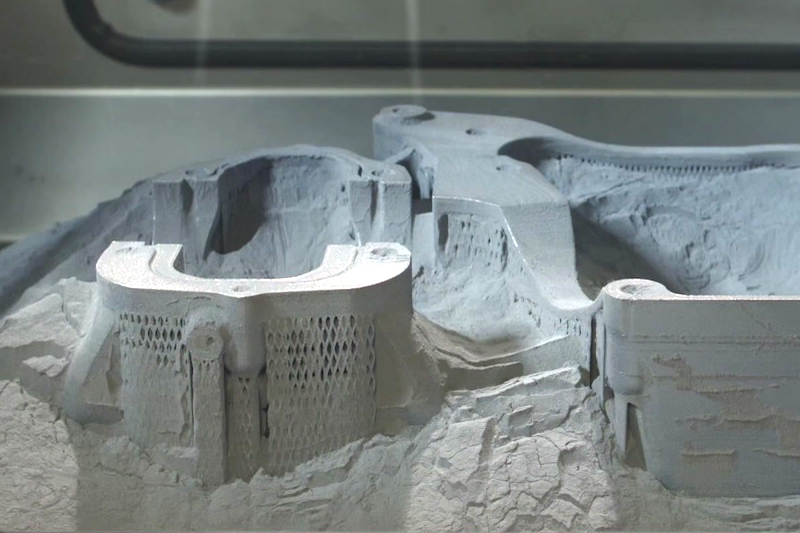

Metal 3D printing involves complex melting processes. Materials such as stainless steel, cobalt-chrome, or titanium are supplied in powder form and melted layer by layer using high-power lasers to form the final part – a process known as Selective Laser Melting (SLM).

SLM Solutions Group AG, based in Lübeck, Germany, is a specialist in Selective Laser Melting and one of the world’s leading manufacturers of metal 3D printers. In their systems, the entire printing process takes place under a protective gas atmosphere inside sealed process chambers. The powder management system – including supply, removal, and reconditioning of the metal powder – also operates within this controlled environment.

At the start of the printing process, the chamber is purged with argon gas. However, as the lasers operate, the atmosphere changes: smoke and fumes are generated, which can interfere with optimal conditions at the build surface. To maintain a stable melting process, the gas atmosphere is constantly circulated and replenished. This can result in a pressure build-up inside the chamber – a critical factor, as excessive pressure can damage the sensitive glass optics of the lasers.

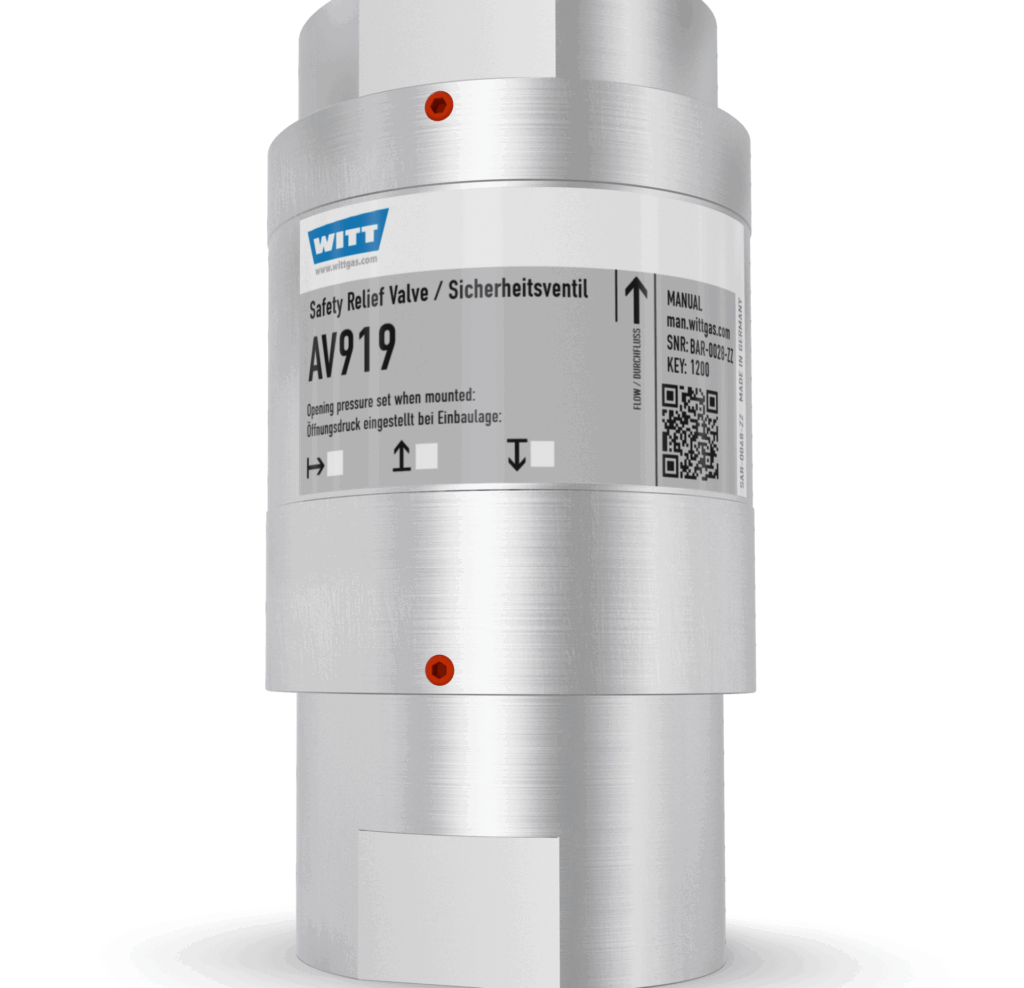

To prevent this, SLM Solutions relies on highly responsive AV 919 safety relief valves from WITT. These valves open precisely at the set pressure and close immediately once the target pressure is restored. This ensures a constant, optimal atmosphere inside the chamber.

“The WITT AV 919 safety relief valve is certainly just a small component in our machines. But without a blow-off valve that is custom-built to meet our specific requirements in terms of material and low opening pressure, we wouldn’t be able to control the chamber pressure with the precision we need,” says Andreas Wiesner, Head of Process and Material Development at SLM Solutions Group AG.

For Andrew Smart, Head of Sales for Gas Safety Devices at WITT, this highlights the core strength of his team: “We design and manufacture small components with a big impact. Complex applications and new technologies demand precision and reliability – and that’s exactly what we deliver.”