The valves are designed for marine and industrial applications such as engines (LT/HT), compressors (gas and air), boilers, heat systems, generator sets and can be used to divert or mix liquids.

By using the latest technologies and durable materials BROEN Clorius Controls have managed to develop a revolutionary valve with significant benefits compared to similar products in the market.

Main benefits:

- Increased system and energy efficiency

- Low maintenance costs

- Low cost of installation

Increased system and energy efficiency

The design of the valve provides best in class accuracy of temperature control and fastest reaction time securing better system efficiency. The right oil temperature secures the perfect oil separation and most optimized running conditions.

Low maintenance costs

Constant ideal working conditions in the system reduces maintenance costs. Furthermore the design only allows a minimum of wear and tear inside the valve which provides for a long product lifetime.

Low cost of installation

Requires only a minimum of supporting equipment which makes installation easy. The valve is self-acting so no need for wiring, power supply etc.

Also used in the automotive industry

The internal thermostat insert is also used in the automotive industry for new engines, where the requirements for correct temperature regulation are very high due to the strict environmental considerations that the industry must comply with as well as a desire to reduce fuel consumption.

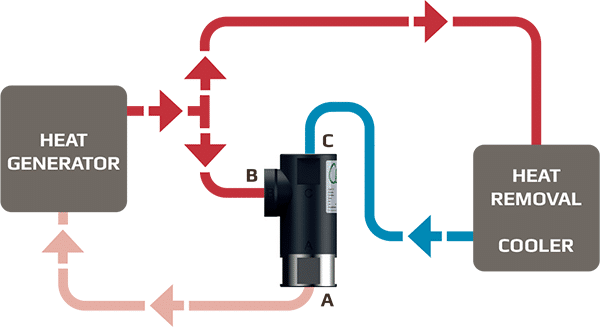

Typical setup

Mixing setup

The hot media enters port B and port C is closed. If the temperature rises, port B begins to close and port C begins to open, forcing the water through the cooler. Port A allows the mixed media to return to the heat generator at the controlled temperature.

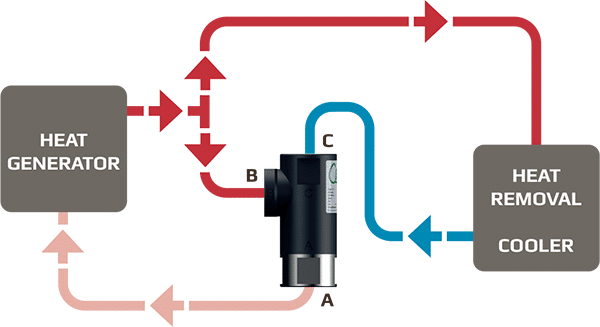

Diverting setup

The hot media enters in port A and depending on the temperature, it is led to the cooler via port C or returns to the heat generator via port B.