Thanks to its capacity for innovation and extensive portfolio of premier valve solutions, Trillium Flow Technologies™ (Trillium) can follow its customers on this journey and help improve their operations in terms of efficiency, reliability, and sustainability. Through its legacy brands, Trillium offers solutions that maximize operations and reduce fugitive gas emissions.

Pressure Relief Valves

Through its Sarasin-RSBD® brand, Trillium offers premium pressure relief valves that can be adapted to suit customers’ process conditions. Product offerings include a spring-loaded pressure relief valve, renowned for its reliable and robust design, which can be customized at will, for example, by opting for a soft seat that remains tight up to 93% of the setpoint.

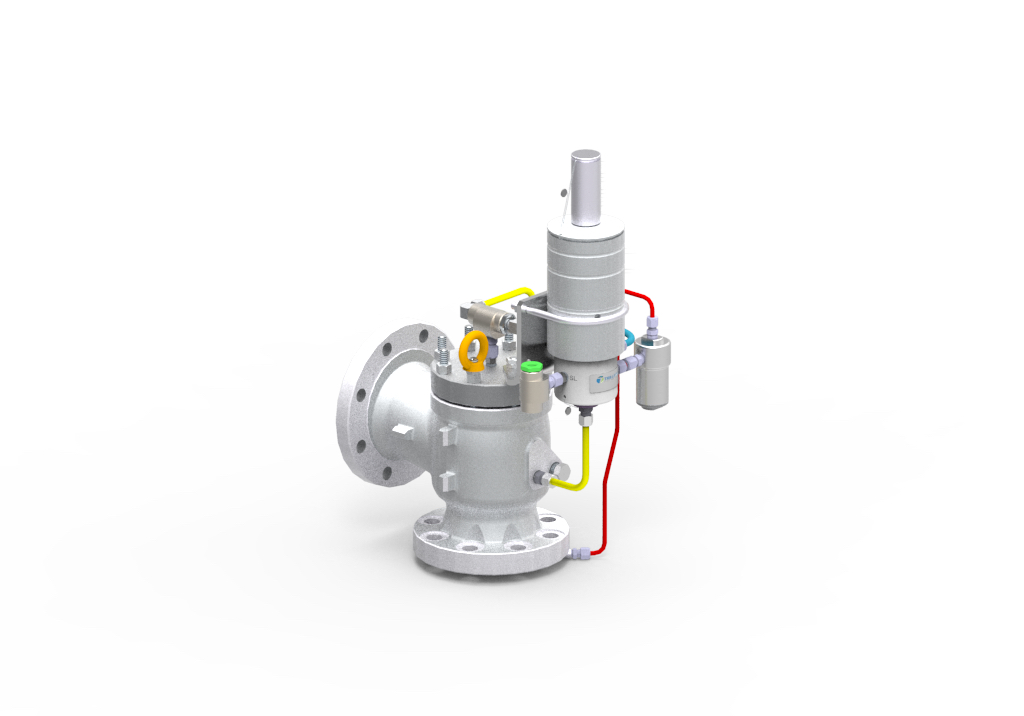

A more advanced solution is the pilot-operated design. With its 30% larger dome seal area compared to the inlet seat, the pilot-operated pressure relief valve remains perfectly tight up to 98% of the setpoint and maintains its no-leakage advantages in any operating conditions.

Sarasin RSBD® POPRV pipeless special design- API 6A 15K

The Trillium Flow Technologies™ Sarasin-RSBD® brand offers a comprehensive range of safety valves for use in the oil & gas, petrochemical, fossil, and nuclear power industries.

Pilot-operated valves offer multiple benefits. Their capability to handle higher pressures and capacities at equivalent sizes compared with the spring-loaded type allows the use of fewer valves for the same application, thus reducing the overall risk of leaks. Moreover, their modulating action pilots make it possible to reduce the total quantity of fluid discharged in an overpressure scenario. As the discharge capacity of the valve is reduced proportionally by the continuous adjustment of the piston lift, this helps to reduce fugitive emissions. Since leak-free operation is a market priority, Trillium also offers a pipeless pilot-operated design to better control fugitive emissions from the valve itself.

Process and qualifications play an important role, too, of course. Pure helium tests can be carried out to measure the internal seat and external tightness, in accordance with ISO 15848-2, to guarantee product performance. The technicians who perform those tests are qualified for Level II in accordance with ASNT-SNT-TC-1A or equivalent. For example, Sarasin-RSBD® supports Shell projects performing fugitive emission production testing as per MESC SPE 77/312 specification.

Isolation & Control Valves

Trillium also offers a comprehensive portfolio of customized isolation (gate, globe, check, and ball) and control/choke valve solutions that assist customers in achieving their fugitive emission reduction goals. Our Red Point®, Batley®, Blakeborough®, and Hopkinsons® valves are designed to comply with ISO 15848-1, which specifies testing procedures for the evaluation of external leakage of valve stem seals and body joints of isolating and control valves intended for use in volatile air pollutants and hazardous fluids. High-quality packing systems are used, certified to API 622, TA-luft / VDI 2440, SPE 77/312 class A & B, depending on the product.

Sometimes, a stem packing alone is not enough protection. In those cases, bellows sealed valves can be provided. This creates a metal hermetical seal, preventing the medium from reaching the stem packing. Trillium supplies a wide range of bellows in stainless steel and nickel alloy in stock for fast-track delivery.

Last year, for example, Trillium was able to support a polyethylene project requiring polyethylene-cleaned isolation valves, including SPE 77/312 class A valves. The project procurement team could not source these high-end (low) carbon- and stainless-steel valves from stock, so they turned to our Red Point® brand, which specializes in non-commodity valves and fast-track delivery. We managed to deliver the valves within the required 12-week lead times.

Trillium also offers service solutions for valves that result in fugitive emissions reduction. Such solutions include the upgrading of flare valves on separation systems for end-users in the oil and gas market. In the past, these valves were commonly specified with a standard Class IV allowable seat leakage rate, with any leakage passing into the flare system. Trillium provides various upgrade solutions, significantly reducing seat leakage and, consequently, the related hydrocarbon gas emissions.

With a product portfolio of world-class brands and thousands of valves installed worldwide, Trillium Flow Technologies has the experience and technological know-how to provide solutions for our customer’s project challenges.