Continuous Level Measurement and Point Level Detection – Even with Sticky Liquids and Agitated Tanks

A crucial element in this production process is glue. It guarantees the permanent bonding of the paper layers and must be available in consistent quality and quantity. Therefore, proper storage and precise monitoring of the adhesive are vital for maintaining an uninterrupted production process.

Glue Storage Application – Requirements for Level Measurement Technology

In a modern corrugated board factory, glue is stored in a dedicated tank. The substance is highly viscous and tends to stick and harden, especially during downtime. To prevent this, the glue is kept in constant motion by an agitator and is regularly replenished in measured doses. For safe and continuous level monitoring as well as precise limit level detection, the company relies on sensor solutions from UWT.

Challenges in Glue Storage

Storing glue in corrugated board production presents several process-critical challenges for level measurement technology:

- Highly viscous, sticky substance prone to hardening

- Material build-up on sensors or tank walls

- Motion from the agitator that can interfere with conventional measuring methods

- Risk of overfilling if limit levels are not reliably detected

- High demands on maintenance-free operation and user-friendly handling in daily industrial use

The Solution: Robust and Tolerant Sensor Technology from UWT

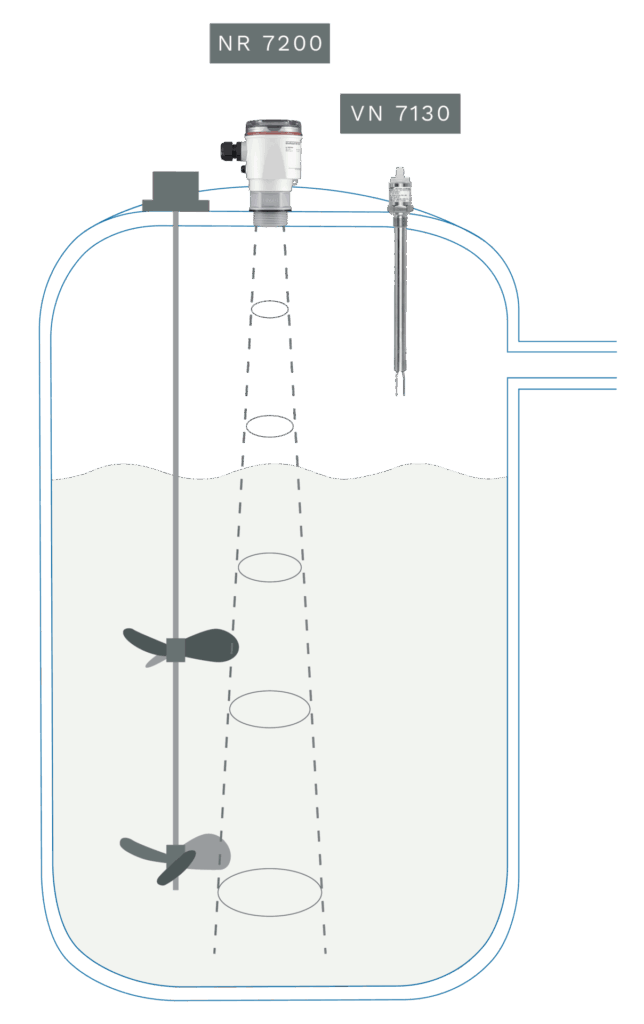

Continuous Level Measurement with the NivoRadar® NR 7200

The free-radiating 80 GHz FMCW radar sensor NivoRadar® NR 7200 enables contactless level detection. With its narrow beam angle of only 8°, the sensor is ideal for narrow tanks – even in applications with integrated agitators. The compact, WHG-certified NR 7200 can be intuitively configured via the UWT LevelApp. The app also allows for fine adjustment to compensate for agitator movement. With its fast response time, the NR 7200 detects measuring ranges of up to 20 m (66 feet). The contactless technology ensures maximum process reliability with minimal maintenance effort, even with demanding media such as glue.

Point Level Detection with the Vibranivo® VN 7130

The Vibranivo® VN 7130 is used as a full detector and reliably detects sticky and viscous media, without the need for sensitivity adjustments. Thanks to its extension tube, the switching point can be precisely positioned at the maximum fill level in the tank, providing reliable shutdown to prevent overfilling. Insensitive to buildup, flow, turbulence or air bubbles, the vibrating fork is ideal for challenging media such as glue. In addition, the limit switch offers flexible remote adjustment of the switching point up to 4 metres (13 feet) – for maximum flexibility in installation and application.

UWT offers a reliable, field-proven solution for this application by combining the NivoRadar® NR 7200 and the Vibranivo® VN 7130:

NR 7200 – The compact 80 GHz FMCW radar sensor:

- Contactless, maintenance-free level measurement

- Narrow beam angle of 8° – ideal for narrow vessels or tanks with agitators

- Simple commissioning via the UWT LevelApp, including fine-tuning for moving elements inside the tank

- WHG certification for safe use in sensitive applications

VN 7130 – The vibration level switch for demanding media:

- Reliable point level detection of liquid or viscous media

- No calibration required, operates without sensitivity adjustment

- Remote switching point adjustment up to 4 metres (13 feet) for maximum flexibility

- Unaffected by buildup, turbulence or air bubbles

- Perfect as a full detector to prevent overfilling or as empty run protection

The successful testing of the limit level detection in close collaboration with the corrugated board manufacturer highlights the practical suitability of the UWT solution and the solution-oriented approach by means of direct dialogue with the customer.