The sensor is attached to the bottom of a tank and emits sonic pulses into the fluid through the tank wall. The pulse travels through tank media, until reflecting from the surface of the liquid and the sensor calculates this level by measuring the return time of the sonic pulse reflections. This sensor also has the benefit of working with not only liquids but with a small amount of suspended particles in solution.

It is compatible with a number of tank wall material; Plastic (≤ 5 mm), Glass (≤ 10 mm) and in some instances metal tanks. However it is recommended that testing will be needed to ensure correct functionality. Due to the principal of operation, this sensor is mostly insensitive to foam buildup due to measurement from the bottom of the tank and is highly shock and vibration resistant.

Main points and Technical Features:

- Auto-configuration

- Continuous analog measurement: 0 / 10 V

- Measuring range: 40 / 1000 mm

- Frequency of measurement: 10 Hz

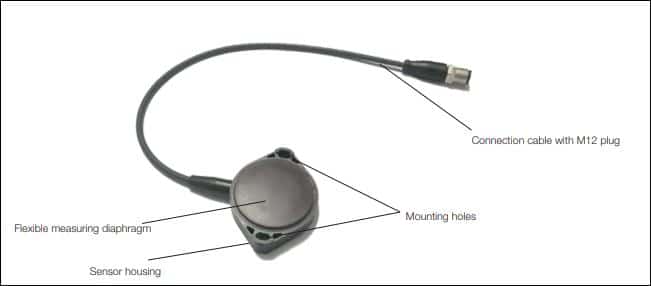

- IP Rating: IP 67

- Power-up time <3s

- Operating Temperature: -35 / +80°C

- Comes pre-cabled with a 3-wire 30cm PUR cable with an M12 connector

Tank, Fluid and Installation Requirements:

- ≥ 200 mm Tank Diameter recommended

- Viscosity of Fluid:

1 / 100 mPas: Specified accuracy and measuring range

101 / 500 mPas (cP): Reduced accuracy and measuring range - Ensure direct contact to the tank wall, if necessary remove paint layers and the sensor is attached with screws or force-fitting to the bottom of the tank (max. 1 Nm screw torque or 10 N press force).

- Install Sonar sensor, so that sonic pulse can travel vertically.