Our core technology: the magnetic drive system

The principle behind our most advanced pumps is the magnetic drive. It is a special sealless design suitable for pumping corrosive liquids that removes the need for mechanical seals, the most frequent source of leaks and maintenance in conventional pumps.

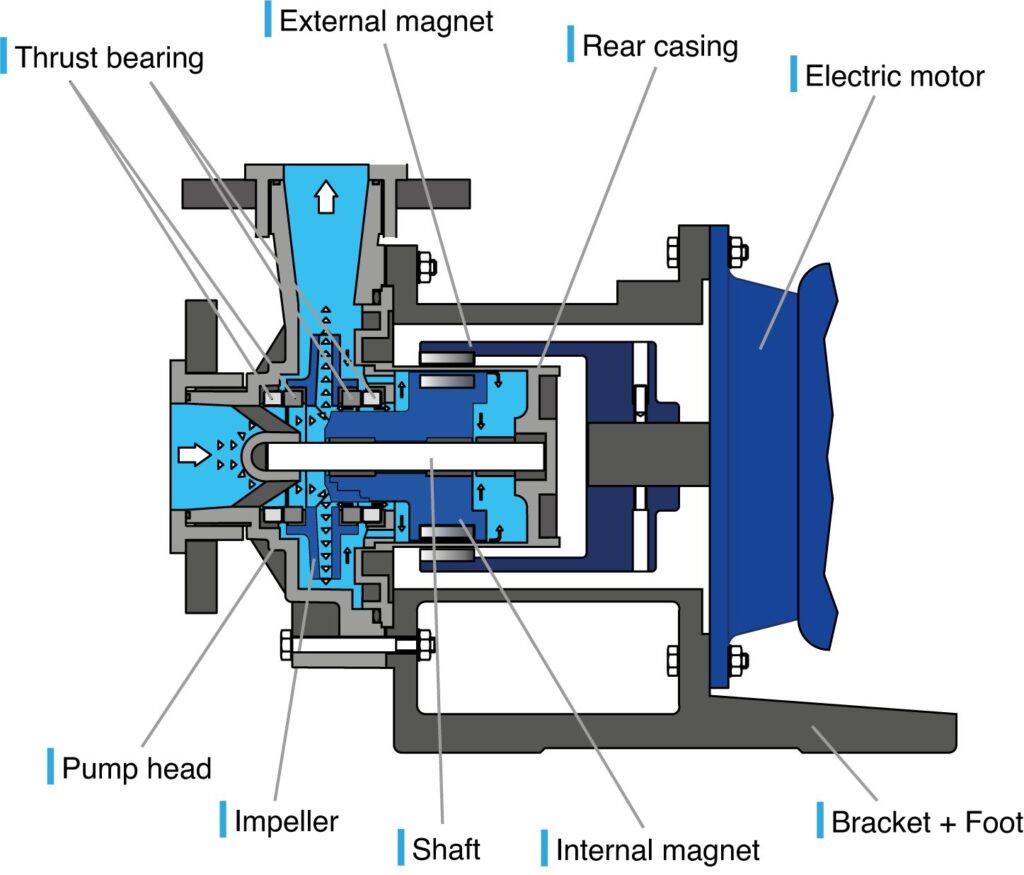

Here is how it works: the pump is driven by a magnetic coupling. An external magnet, mounted on the motor shaft, transmits torque through a stationary rear casing to an internal magnet, which is hermetically sealed inside the pump. This internal magnet is connected to the impeller, driving the fluid movement.

The rear casing creates a solid, leak-proof barrier between the pumped liquid and the atmosphere. The result is a hermetically sealless design that provides total fluid containment.

Key advantages of GemmeCotti’s magnetic drive system

The innovative sealless design of our magnetic drive pumps offers tangible benefits for safety, reliability, and cost-efficiency.

- 100% leak-proof: our pumps guarantee zero leakage of chemicals and fugitive emissions, ensuring total operator safety and environmental protection.

- Minimal maintenance: with no seals to wear out, service, or replace, maintenance costs and process downtime are drastically reduced.

- High reliability: the simple and robust design leads to a longer service life and dependable performance, even with corrosive and dangerous liquids.

- Simplified installation: the magnetic coupling design removes the need for time-consuming pump-motor alignment, saving time and preventing common installation errors.

- Efficient Performance: a high-torque magnetic coupling ensures that power is transferred from the motor to the pump smoothly and effectively.

Our mag drive pumps: a solution for every application

To meet the diverse needs of chemical handling, GemmeCotti offers a wide range of magnetic drive pumps. Each design is engineered to provide a reliable and efficient solution for a specific operational challenge.

- Mag-drive centrifugal pumps: they are the ideal choice for most standard to high-flow chemical transfer and processing applications where reliability and efficiency are key.

- Mag-drive turbine pumps: these pumps are designed for tasks requiring high pressure at low flow rates, delivering the smooth and steady performance needed for dosing, sampling, and circulation.

- Mag-drive rotary vane pumps: Anti-corrosion industrial pumps suitable for pumping hydrocarbons, solvents, heat transfer oils, refrigerants, cryogenics and radioactive liquids.

For a safer, more reliable, and low-maintenance pumping solution, trust the Italian specialists in sealless magnetic drive technology. We are ready to find the perfect pump for your needs. Contact us for a free quotation or more information at info@gemmecotti.com, call +39 02 96460406, or visit our website www.gemmecotti.com.