We produce high quality, reliable and long-lasting pumps. Our wide range of products includes magnetic drive centrifugal pumps, magnetic drive turbine pumps, magnetic drive vane pumps, vertical pumps, mechanical seal pumps, manufactured in thermoplastic materials (PP or PVDF) or metallic materials (AISI 316). Recently we have developed our production adding a new self-priming magnetic centrifugal pump model HTM SP.

Our new HTM SP Pump

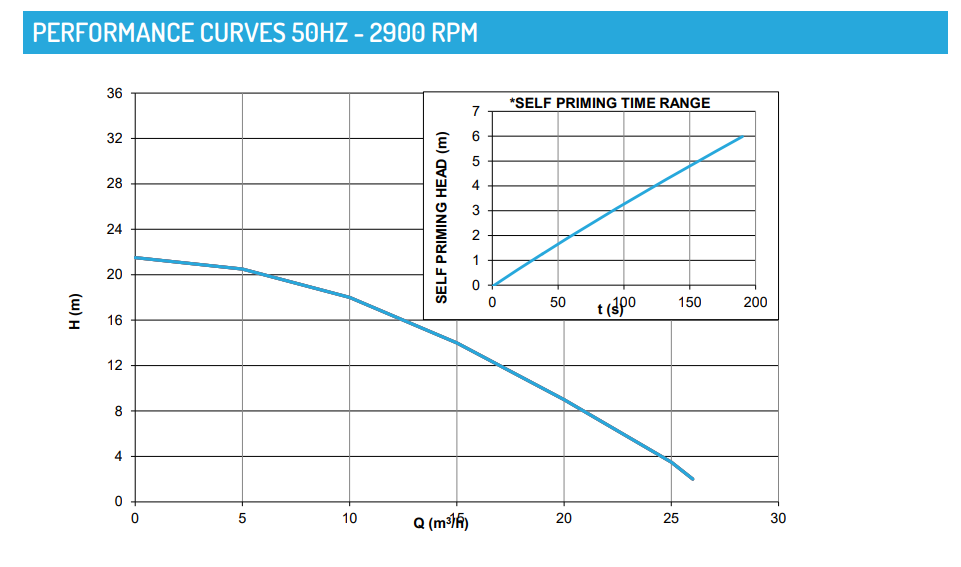

The new GemmeCotti HTM SP pumps combine the typical features of our mag drive centrifugal pumps with the self-priming capability. These pumps can prime up to 6 meters at sea level.

Main features

Materials

HTM SP pumps are made of Polypropylene (PP), a thermoplastic material that ensures the best resistance to most chemicals. All the internal plastic parts are obtained through the injection moulding process that we directly manage in our sister company Gemme Plast.

Performance capability

The new magnetic centrifugal pump self-priming HTM SP can reach a capacity of 25 m3/h and a head of 22 m. The suction connection of this pump can be customized in 3 welded configurations according to your needs (frontal, on the right and on the left).

Magnetic drive pump design

The magnetic drive system has many advantages:

- no mechanical seal;

- no leakage or emissions;

- no waste of liquids;

- environmental sustainability;

- reliability and safety;

- reduced maintenance and consequent long term savings;

- no need for a pump-motor alignment.

Mag drive pumps have a special sealless design that is suitable for pumping corrosive and dangerous liquids thanks to the high chemical resistance and to the absence of leakage and emissions. The structure is really simple and it requires very little maintenance with consequent savings in terms of repairing, spare parts and machine downtime costs during the pump life.

How does a magnetic pump work?

In magnetic pumps, there is an external magnet which is connected to the shaft of the electric motor.

The synchronous motion is transmitted from the motor to the rotor (consisting of the internal magnet and the impeller) through the external magnet. The two magnets never come into contact, they are moved by the magnetic field only. The impeller connected to the internal magnet spins around a static shaft and the liquid moves through the pump. The whole hydraulic part is hermetically sealed: in the space between the magnets there is a rear casing which closes on the pump head and prevents the pumped liquid from coming out of the pump.

The pumped liquid must be clean, without solids in suspension (max. quantity of solids: max 2% – max 1mm).