The connection of new gas production sources to a gas plant facility have often required mechanical relief devices for the protection of gas production facilities or pipelines. New production sources connected to existing pipelines require the pipeline to be protected against potential overpressure, which may result in the release of hydrocarbons to the atmosphere or undesirable burning of these hydrocarbons via a flare system. International standards (API 521, Code Case 2211 of the ASME Section VIII, Division I and 2, ANSI/ISA 84.01-2004, IEC 61511) are now in place to allow for the application of high-reliability safety instrumented systems to replace traditional mechanical relief devices and to remove the need for flaring.

Economic Advantages:

- Platform weight savings

- Space savings

- Project cost reduction

- Increase operating pressure and production

- Increased diagnostics

- Increased flexibility

- Mitigate risk

- Reduce spurious trips and downtime

- Reduce CAPEX (relief, flare, downstream piping)

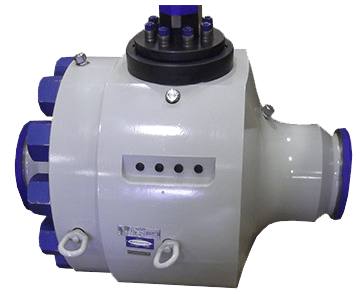

Fully Integrated HIPPS Solution

ValvTechnologies’ scope of supply would typically include:

- Shutdown valves (SDV) API, PSL level 3 (with optional flame protection), utilizing ValvTechnologies’ zero-leakage ball valves

- Actuators (hydraulic or pneumatic)

- Instrumentation, including pressure transmitters

- HIPPS logic solver

- Chemical injections system

- Choke control

- Complete HIPPS skid design and fabrication, if required

Final Elements:

Our HIPPS solutions utilize the ValvTechnologies’ NexTech® E, trunnion mounted, double block and bleed ball valves that are suitable for both the API and ANSI codes. NexTech® E offers an innovative solution:

- One-piece top entry body

- Bi-directional seat tightness

- Controlled seat loading

- Lower torque

- Resistant to particulates

- In-line serviceable

- Double block and bleed

The Logic Solver:

The development of the HIPPS package is governed by IEC 61508 / 61511 which define specific guidelines to configure the SIS to provide the necessary risk reduction and meet the required Safety Integrity Level (SIL).

The Logic Solver uses standard, proven function block software and available options which include partial stroke testing, valve function logging (to support preventative maintenance regimes), communications to all major DCS systems and customized third party communication interfaces. The SIS controller can be provided from a range of IEC 61508 SIL 3 certified platforms, to include scalable 2oo3, 1oo2D and simplex architectures, with SIS choice dictated by functionality and availability requirements, system cost and customer preference.