Equflow develops and produces modular flow sensors according to a unique and extremely reliable principle. It is suitable for the measurement of the flow rate of various liquids in a wide range of applications. Equflow’s sensors are so-called turbine flowmeters combined with an infrared sensor.

With a disposable sensor version, the technology company from the Dutch province Brabant is capitalizing on the rise of disposables in the biomedical and pharmaceutical industries. The use of these disposable flow sensors reduces process times and saves energy. A lengthy and intensive development and validation process preceded the commercial introduction.

The result is an extremely accurate measurement system that guarantees a reliable flow measurement. The key to this is a unique automatic calibration system combined with virtually frictionless moving turbines in plastic tubes.

In this whitepaper, you can read all about the composition, functioning and application of the flowmeters tailored to single use.

Principles of Flow Measurement

A flowmeter measures the quantity of liquid or gas that flows through a tube per unit of time: the flow rate. Depending on the application, the instrument measures the mass, volume and/or flow rate of the medium.

There are various techniques for measuring and even more types of flow sensors that measure the flow of gasses and/or liquids. Which technique is used depends on four key questions. Why do you want to measure flow? What do you want to measure? How accurate must the measurement be? And at what price?

Turbine Flowmeter

Equflow uses the turbine flowmeter for flow measurement. This measurement technique has two significant advantages: the accuracy and repeatability when measuring the flow of liquids with a low viscosity. Equflow has developed a mechanical construction that results in an almost frictionless turbine movement that barely causes any wear and tear. In a performance test in which an Equflow flowmeter was subjected to a piston pump system for an entire year, the output signal was even better after one year than at the start of the test.

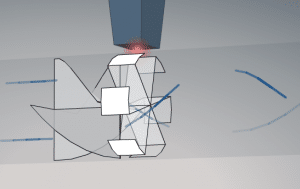

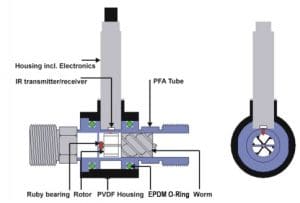

The infrared sensor in a turbine flowmeter measures the number of pulses that the reflectors on the six turbine blades generate. The more pulses a turbine emits, the faster the medium flows. The sensor processor then converts the number of pulses per time unit into speed and volume. In a disposable application, it is important that the sensor is placed separately from the turbine shaft.

There are alternative techniques for measuring flow but virtually all are unsuitable or too expensive for one-time use.

Single Use in Biomedical and Pharmaceutical Technologies

In biomedical and pharmaceutical technology, there are strict conditions for flow measurement. The measurements must of course be reliable and accurate. But they must also take place in sterile conditions. The single-use flowmeters from Equflow are therefore produced in a clean room and can be sterilized with gamma radiation if required. A bioreactor, for example, must be able to be quickly and easily cleaned after each production run. The same is true for a dialysis system, for an intravenous drip pump, and for laboratory equipment. Actually, it applies to all sorts of machines and equipment through which liquids flow and in which no single contamination or infection may occur. Moreover, shorter process and cleaning times ensure lower production and energy costs.

These and many other conditions necessitate single-use components for biomedical and pharmaceutical technology, including sensors for one-time use.

How Does it Work?

A flow sensor application from Equflow for biomedical and pharmaceutical technologies is constructed in a modular fashion. In principle, the sensor system consists of four and sometimes five components, of which the turbine tube with turbine and the bar code scanner are the most advanced parts. They guarantee the accuracy and reliability of each flow measurement for years.

The components:

• turbine tube for single use;

• bar code scanner system for automatic calibration;

• choice of housing for the disposable tube;

• electronics for flow measurement.

Turbine Tube for Single Use

A turbine tube for single use is placed as a connector between two hoses that transport the liquid from or to a component of the machine or the device. The tube contains the mini-turbine, whose sensor detects the reflectors on the turbine blades through the transparent tube wall. The turbine has so little mass that the flow variations can be easily followed. Equflow offers two types of transparent disposable turbine tubes.

Perfluoroalkoxy Alkane (PFA) Turbine Tube

PFA is a fluoropolymer that is resistant to aggressive chemical liquids, corrosive liquids and fuels. In addition, the tubes can be used for clear, opaque and neutral liquids. However, PFA is not suitable for gamma radiation. Equflowproduces three versions of this type of tube.

Polyvinylidene Fluoride (PVDF) Turbine Tube

This type of disposable tube is made of PVDF. PVDF is also a fluoropolymer that is resistant to chemicals, acids and bases. Due to its hardness, the material is resistant to higher pressures than PFA. Moreover,PVDF is suitable for sterilization with gamma radiation. Equflow produces three versions of this type of tube. Equflow has recently developed a new flow sensor where the 0045 type is able to measure from 20 milliliters per minute to 1 liter per minute. The default 0045 type has a flow range of 30 milliliters per minute to 2 liters per minute.

Bar Code Scanner System for Automatic Calibration

The sensor electronics base the amount and/or flow rate of the liquid shown on a display on the number of total pulses counted and the number of pulses per unit of time (frequency). The passing of each turbine blade means one pulse. The number of pulses per liter of liquid during a linear measurement is the K factor, or Kf. At a K factor of 2,000, one liter of liquid provides 2,000 pulses.

In disposable applications, the K factor is especially significant for the reliability and repeatability of the flow measurements. During each measurement with a new turbine tube, the measurement must take place according to the same parameters. Although the turbine moves almost without friction in the liquid flow, minimal variations occur during the production of the tubes. As a result, the K factor of tubes, which are similar according to the specifications, also varies.

Without calibration, the exchange of turbine tubes would lead to undesirable measurement deviations.

Suppose that you use a tube with a K factor of 1,998 instead of one of 2,000 on which the system is set. With every 1,000 liters, more than 1 liter difference in the amount of liquid occurs. In a medicine formula, that can mean the difference between a good batch and a batch that is rejected.

Equflow provides each turbine tube with a unique bar code that contains the K factor of the tube. during production, Equflow determines the K factor for each tube in a calibrated test set-up.

The fluid properties and other specifications are set in the process system of the production or control process. When the turbine tube is changed, the operator only has to scan the bar code with the bar code scanner. This automatically processes the K factor of the tube for the recalibration of the system, so that a reliable measurement is guaranteed.

Choice of Housing for the Disposable Tube

The principle of the Equflow sensors is based on the measurement of the reflections of the six turbine blades in turbine tubes. Different single-use and disposable models are available for the disposable tube. The models are suitable for various types of turbine tubes. It contains an optical sensor with an infrared light source and a receiver that detects the reflections of each blade through the transparent tube wall and converts them into a square wave pattern, also called pulse wave.

The frequency of the wave pattern is directly proportional to the flow rate of the liquid within a certain bandwidth, also called the linear measurement range or flow range. The flow range is determined by the diameter and the material of the turbine tube. The flow range is limited by the minimum flow in liters per minute at which the turbine runs in a stable manner and provides a constant frequency. The total range is determined by the flow speed within which another linear measurement signal is given.

By measuring the number of pulses, you know the quantity of liquid that has passed the sensor. The pulse frequency corresponds with a certain speed of the liquid stream per minute. The sensor can be used for both the controlling of processes as well as for the pure measurement of the flow and total volumes.

The Tube Holder System

The Tubeholder system is a solid system that makes exchanging the tubes easy and fast. It is provided with four screw gaps, so it can easily be secured on to your system. The Tubeholder system is available for PVDF and PFA flow tubes and cover flow rates from 20 millilitres up to 120 litres per minute.

The Clip Mounting

The clip mounting is a lightweight sensor, which allows a flexible way of connecting the electronics. The clip mounting covers flow rates from 20 millilitres up to 40 litres per minute and is also available for PVDF and PFA flow tubes.

The Click Housing

The click housing is mostly used in applications in which tubes do not have to be exchanged that often. This system is available for PFA tubes only. The two available sizes cover flow rates from 60 millilitres up to 20 litres per minute.

The Clamp System

The clamp system is Equflow’s newest single use model that makes exchanging tubes easy and fast. This system can be used on its own, but it is also provided with a screw gap to secure it onto your current system. The clamp system covers flow rates from 20 millilitres up to 20 litres per minute and is available for PVDF and PFA flow tubes.

Electronics for Flow Measurement

To convert the digital turbine pulses of the infrared sensor into quantities and speed, electronics in the form of a controller is required. Equflow has four different types of controllers, each one suitable for certain measurements

and/or controls in a biomedical device, pharmaceutical machine or other medical application.

Certification and Validation

The permanent and disposable flowmeters are available with a complete set of validation documents and calibration certificates upon request.

About Equflow

Equflow has perfected the flow measurement of liquids. In ten years, the technology company located in the Dutch province Brabant has thus further developed its own invention into commercial solutions for various applications in which flow measurement is crucial. The modular sensor system with interchangeable components has been on the global market since 2010.

Equflow develops and produces – under high quality standards – permanent and disposable flowmeters and all required components. The flowmeters are used for measuring flow in the following application areas, among others:

- Biomedical and pharmaceutical technology;

- Water purification, production and treatment;

- Installation technology (central heating & plumbing);

- Dosing pump systems;

- OEM equipment and machines;

- Fuel distribution;

- Semiconductor production.

Equflow’s sensor technology stands out in its modularity and in the accuracy, reliability and repeatability of the measurements.

The perfection is expressed in all flowmeter components and the software. The bar code scanner for the automatic calibration of the measurement system plays a key role in single-use applications. Furthermore, Equflow’s customers value the affordability and opportunities for customization of the sensor system compared to other single-use solutions.

In addition to production and clean room facilities, Equflow has engineers who, together with the customer, fine-tune the sensor system for the applications in which the flow of liquids must be measured and/or controlled.