Recently commissioned, this new capability extends the services of the 3,000 square meter workshop and now provides extensive resources for repairing rotating equipment and assembling pumping equipment.

The Hope Valley Facility opened during October 2015 to support the company’s growing activities in Western Australia, South Australia and Northern Territories. KSB’s business activities are evenly split between western and eastern Australia, but there is a difference in the range of the industry sectors served, and this is reflected in the types and sizes of the pumps supplied. The Perth operation is established in the mining industry, where very large pumps capable of handling vast quantities of aggressive liquids and slurries are required. It also has a significant presence in the water supply industry, being a preferred supplier to a major Western Australia Water Authority and contracted to deliver maintenance for desalination plants in Western Australia.

Taking the Test Bay in KSB’s Australian HQ in Bundamba, Queensland, as its template, the new capability in Hope Valley has been designed in accordance with ISO:9006, and the check list and design criteria stipulated by KSB headquarters in Germany. This means that it is in line with KSB’s expectations and all other KSB Test Bays around the world. Significantly, it enables engineers to access a fully automated system which can capture data from other KSB test facility data bases around the world. The system can be updated as changes and requirements evolve.

“As one of Australia’s leading providers of pumps in all industries we are in an excellent position to fully support all our customers pumping needs; from process water, drinking water, wastewater, firewater, dewatering, high pressure pumping, desalination, slurries, life science, building services, irrigation or oil & gas etc, we are there to assist. With our ongoing investments in Australia we are committed to expanding our services even further to support all businesses and the resourceful and enterprising people of this great country,” reports Dave Alexander, KSB Australia Managing Director.

Test Bay capabilities

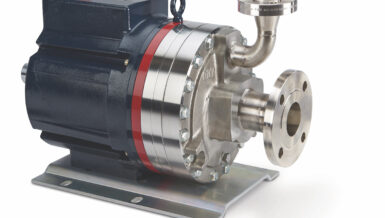

The capabilities of the test bay reflect the nature of KSB’s installed base across Australia and the need to be able to test pumps of all sizes (Fig.2).

The 90,000 litre clean water test circuit is designed for flow rates of up to 1500l/s at 40 bar pressure and is equipped with manifolds ranging from 80mm to 600mm. For larger flows and higher pressure, testing can occur at reduced speeds and affinity laws can be used to verify test results.

The 12,000 litre wastewater test circuit is designed for flows up to 200l/s at 14 bar pressure and is equipped with manifolds ranging from 80mm to 250mm. The test bay is equipped with variable speeds from 7.5kW to 630kW.

Customer Benefits

The commissioning of the Test Bay means KSB can now test all pumps after refurbishment, ensuring that it is repaired to meet OEM benchmarks, regardless of the manufacturer. KSB SupremeServ is dedicated to ensuring that customers’ pumps are repaired to the highest quality and to guarantee optimum functionally after repair. This four part concept encompasses consultancy and analysis, commissioning and start-up, operational support and repair/maintenance. Delivered by KSB specialists, all these services are available throughout the planned operating life of the pump.

Consulting with KSB engineers at the outset helps to identify the operating parameters of selected pumps and systems by market leading smart tools such as the KSB SES box, KSB Guard or Pump Meter. Once the appropriate pump has been selected KSB SupremeServ participates in commissioning to ensure that the delivered equipment meets the system design envelopes. Service and readily available spare parts solutions make for the smooth operation of pumps and valves to ensure unparalleled availability. This capability extends to taking servicing products from any manufacturer. KSB provides tailor-made service and has in-house reverse engineering capabilities of rotating equipment should the need arise to develop or reproduce a specific part.

The first testing programmes commenced in August 2020, with 11 Mega CPK pumps from KSB India and four high pressure Multitec pumps from KSB France being subjected to functional testing by a major customer’s independent inspection authority. Although all the pumps would have undergone testing in their respective manufacturing plants, the opportunity for the customer to conduct their own tests in accordance with operational requirements was a much appreciated capability. Initial reports from the customer indicated that the facility was a very professional set-up and the ease of testing was excellent.

KSB still offers the option to perform witnessed or non-witnessed pump performance tests at its manufacturing plants worldwide prior to shipping the equipment, however KSB can now also offer to perform verification tests locally, within Australia.