Quattroflow™ develops and manufactures, in close cooperation with our customers, quaternary (four-piston) diaphragm pumps specifically designed for critical applications in the biopharma as well as food and beverage industries.

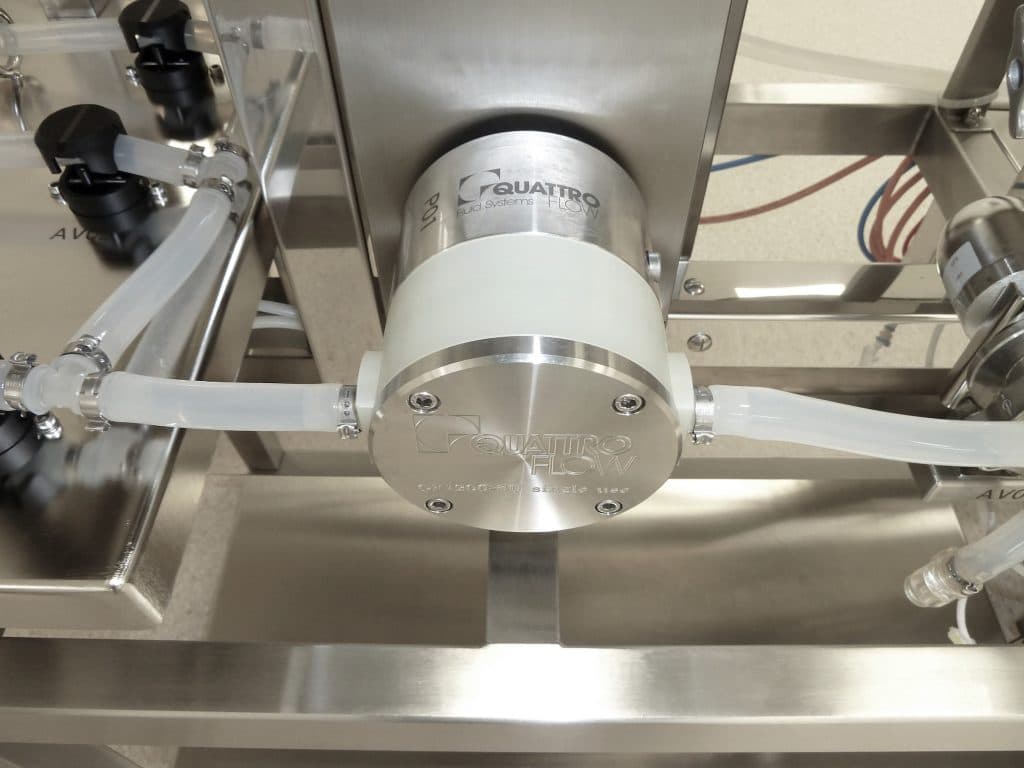

The Quattroflow pump’s method of operation allows it to gently, safely and securely convey aqueous solutions and biological products that are shear sensitive. The four-piston design does not include a mechanical shaft seal or wetted rotating parts, ensuring total product containment without abrasion. Additionally, the four-piston pumping principle enables risk-free dry running, low pulsation, self-priming, and minimal particle generation. Quattroflow pumps are available with cleanable multiple-use stainless steel or disposable single-use plastic pump chambers.

The Quattroflow™ story dates back to the 1990s when one of the company founders was working in the filtration technology sector and found himself in need of a pump that would produce a protein solution. After teaming up with the second company founder, an electric specialist, they developed a new pump technology ideally suited for that type of application – a diaphragm pump with four smooth-action pistons. Based on this invention, the pair founded Quattroflow in 2000 using the location of an existing electrical installation company.

In 2011, Quattroflow was acquired by PSG, a Dover company, and moved into the Almatec manufacturing facility located in Kamp-Lintfort, Germany.