AVVA Pharmaceuticals AG is a major pharmaceutical company operating in over 40 countries worldwide. They have over 25 years’ experience in the pharmaceutical sector.

The customer is continuously growing and needed to expand one of their production plants.

They needed a fully automatic and very complex production plant for liquid pharmaceutical formulations (syrups and suspensions) that could be used for manufacturing a certain product while being cleaned and prepared for manufacturing another product at the same time.

The plant had to be connected to three different filling lines. The suspensions also required recirculation during the process to avoid solid particle sedimentation. It had to be equipped with a CIP system and SCADA.

INOXPA installed different equipment in different areas due to the needs of the different production processes.

- In one area was installed:

- 2 tanks of 2400 liters (one for preparation and one for the storage).

- 1 tank of 250 liters (for API preparation and for small batches).

- 2 manifolds (connecting the plant with the 3-filling line and CIP)

- 1 blender

- Pumps

- In an ATEX zone was installed 1 tank of 250 liters (for API preparation and for small batches) where the explosive ingredients are used.

- In the technical area above it is installed CIP skid and cooling/heating stations for the reactors.

- The control system SCADA based on Win CC professional with 5 thin clients

Thanks to INOXPA’s installation, AVVA Pharmaceuticals get some advantages that they haven’t before:

- The system installed with manifolds allows to produce different types of products or CIP washed in the same time. It led to big complexity of the system and we had to work hard to made interface as logical as possible.

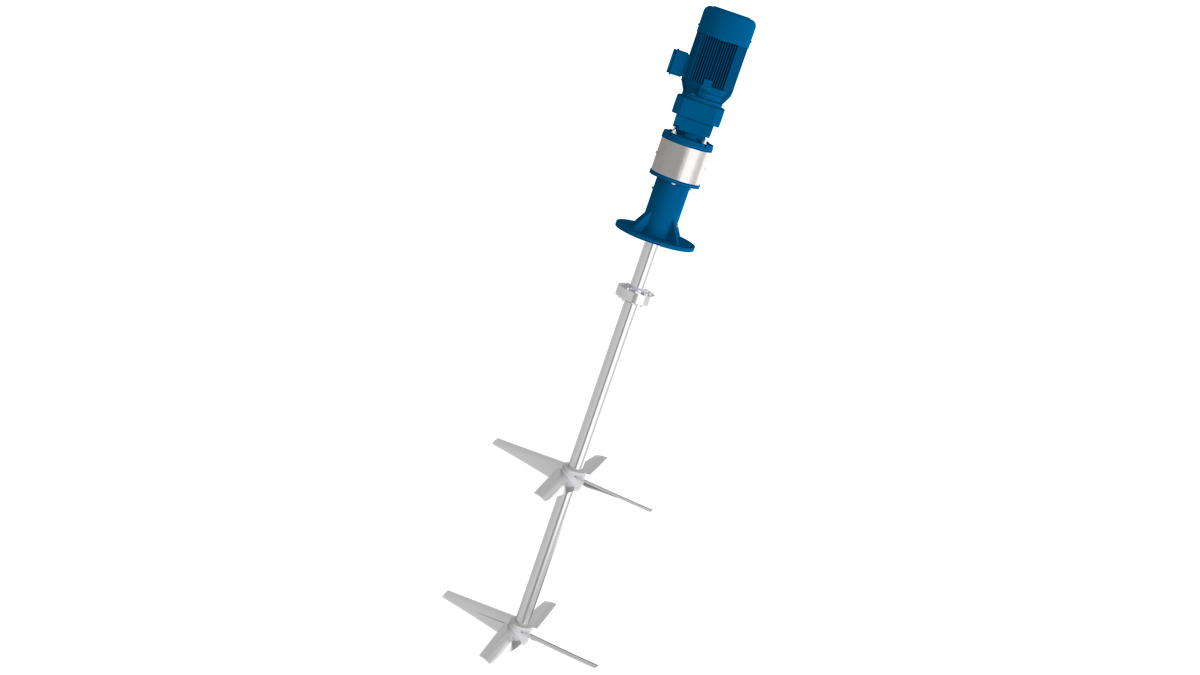

- Big tanks are equipped with the magnetic agitators that helps to maintain the suspension be homogeny at the last stage of production.

- Diaphragm valves manifolds were mixproof performed any hub was performed with 3 valves to determine any leakage.