Silverson pioneered the types of mixers that offer ultra-hygienic production, stable emulsions and thorough mixing for functional efficacy of pharmaceutical creams and ointments. Silverson Machines explains the process in its latest “how-to” video, “How to Make Pharmaceutical Creams”.

Pharmaceutical creams and ointments of all varieties, whether water in oil (w/o) or oil in water (o/w) emulsions, depend on thorough blending to ensure efficacy in the final product. Each type offers different production challenges. In addition, maintaining production volumes is equally as important as meeting or exceeding the strict hygienic guidelines dictated by regulatory bodies like the Food and Drug Administration.

Ultra-Hygienic High Shear

Silverson mixers help achieve a thorough blend of active pharmaceutical agents with other ingredients for consistency and functionality in the end product, repeatable every production run. Whether the product begins with a w/o or o/w phase, intense shear reduces the droplet size to ensure a fine, stable emulsion, eliminating the agglomerates and lumps common with conventional agitators. Droplet sizes of two to five microns are common, but finer droplet sizes can be obtained depending on the type of emulsion. In a short time, all ingredients are fully hydrated to obtain required viscosity and develop yield, while active ingredients are thoroughly dispersed throughout the batch to maximise their effectiveness in the final product.

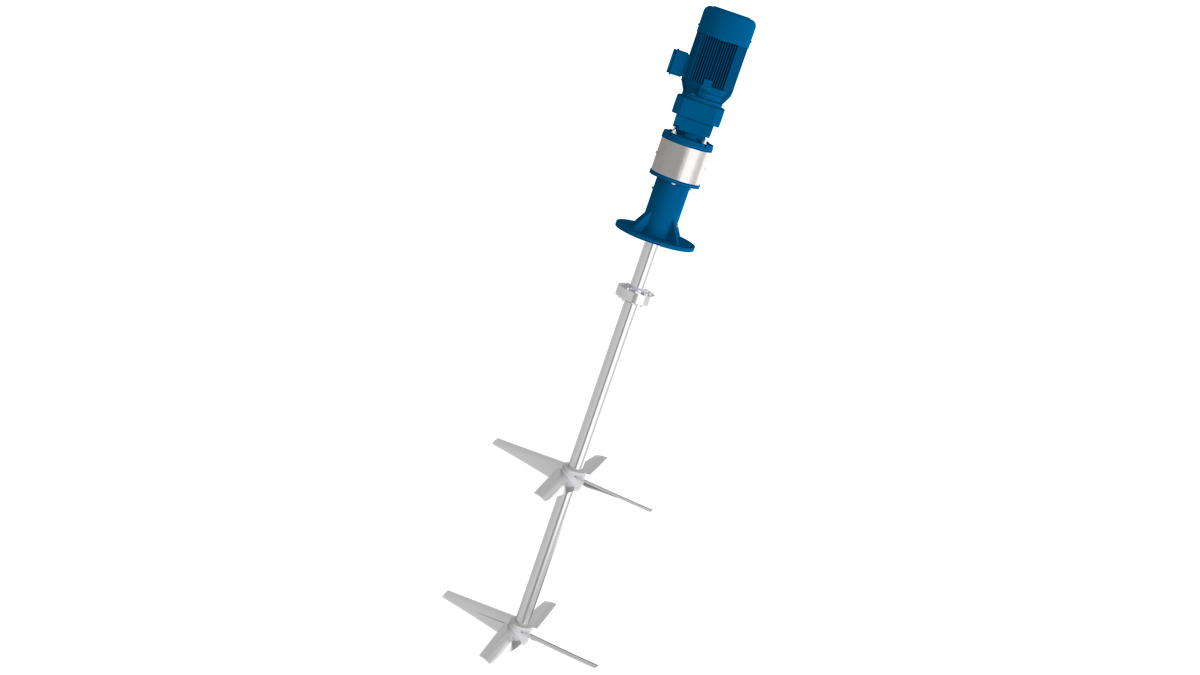

Silverson manufactures a variety of different mixers suitable for pharmaceutical grade products depending on the application. Higher viscosity products would benefit most from the High Shear Bottom Entry Mixer with a stirrer/scraper to help maintain uniformity in the vessel. For large batches, Silverson In-Line Mixers offer greater efficiency at high volumes.