If the problem is severe enough, water hammer can cause damage to pumps, pipe ruptures, or broken gaskets or welds, creating a safety hazard for anyone in the vicinity.

To eliminate water hammer from your system, we first must understand the various harmful effects it can have and what solutions are available to resolve them.

The harmful effects of water hammer

Water hammer occurs when a fluid in motion suddenly stops or changes direction. The fluid sends a shockwave—called hydraulic shock—through the system, causing vibration or banging in the pipes immediately following shutoff.

Water hammer is an issue that can cause damage to your flow system and overall operation. The most common consequences are:

- Pump and flow system damage: Water hammer can cause pumps, valves, and other instruments to be damaged. Seals and gasketed joints can fail, and the integrity of welded joints and pipe walls can be compromised.

- Ruptured pipes: Local pipeline failure as a result of extreme pressure spikes can lead to complete rupture, which can be costly and time-consuming to repair.

- Accidents: Ruptured pipes can endanger maintenance staff and other employees. In some facilities, such accidents can put them at risk of electrocution, slips, and falls.

- Leaks: When pressure waves hit the pipes, they can damage connections, joints, and fittings, leading to leaks. These weak spots may go unnoticed or grow slowly over time, exposing surrounding equipment to potential damage.

- External property damage: The water from a ruptured pipe can cause external damage or corrosion to infrastructure and electrical devices.

- Unscheduled downtime: If a pipe ruptures or causes property damage, repairs can be lengthy. This can lead to lost production and other financial losses related to the repair.

Our solution

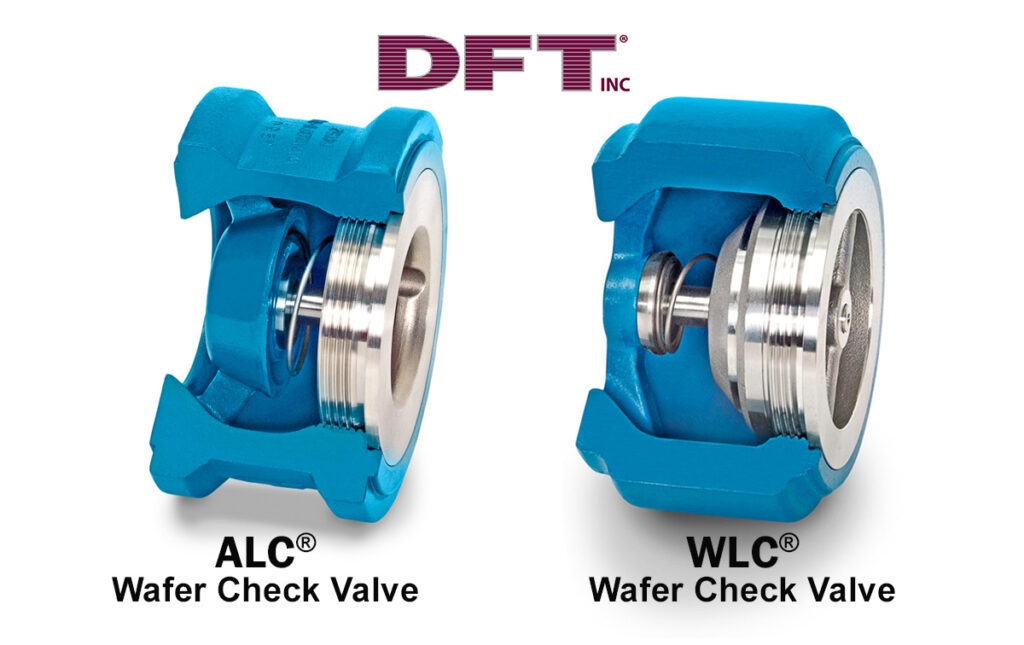

DFT® is a world-class manufacturer of check valves available in various styles and for a wide range of industries and applications. Our ALC® and WLC® are wafer-style check valves that help to prevent water hammer and reverse flow. They can be a direct replacement for failing double-door or dual-plate check valves. DFT® non-slam, spring-assisted, and center-guided check valves are designed to maximize the service life of your flow system.

The ALC® Wafer Check Valve is a compact, lightweight spring assisted valve with API 594 face-to-face dimensions that fit between mating flanges. The body is constructed from corrosion-resistant stainless steel and carbon steel, and it can be used in vertical or horizontal installations. Compatible with steam, gas, or liquid process flows, the ALC® check valve features spring-assisted silent closing.

The WLC® Wafer Check Valve is a lightweight, spring-assisted valve suitable for a wide range of pressures, temperatures, and fluids. With a carbon steel and stainless steel body, the WLC® features a protected Inconel spring and dual-guided stem. Optional body materials such as Alloy 20, Hastelloy®, Duplex SS, Titanium, and Inconel® 625 are available.

Benefits of our ALC® and WLC® Wafer Check Valves

To eliminate water hammer and reverse flow from your industrial piping system, look no further than DFT®’s ALC® and WLC® Wafer Check Valves. These non-slam check valves do not rely on gravity or reverse flow for their closure. Instead, as the forward velocity of the fluid slows, the spring assist on the valve starts to close ahead of flow reversal. The DFT® spring-assisted operation ensures that the valve does not slam shut, thus preventing water hammer and its associated noise and damage. Here is an overview of the features and benefits of each product line.

ALC® Wafer Check Valves

- Available in sizes 2” to 24”, Class 150 & 300

- Meets API 594 face-to-face dimensions

- Center-guided

- Suitable for gas, liquid, or steam applications

- Can be installed vertically or horizontally

- Can be custom-sized to your application

- Low maintenance, long service life

- Tapped holes in the body to aid installation (only 10” or larger)

- Download the ALC Cut sheet

WLC® Wafer Check Valves

- Available in sizes 1” to 10”

- Class 600 & 900/1500 RF meets API 594 face-to-face

- Class 150 & 300 RF meets MSS 126 face-to-face dimensions

- Center & dual-guided stem

- Works with a wide range of temperature/pressure combinations and fluids

- Can be installed vertically or horizontally

- Can be custom-sized for your application

- Available for Severe Service (WLC® SS) and Boiler Feed (WLC® BF) severe duty applications

- Low maintenance, long service life

- Download the WLC Cut sheet

Prevent water hammer with DFT® check valves

For more than 75 years, DFT® has been solving our customers’ check valve issues, preventing check valve failures, and eliminating water hammer problems. We offer cost-effective rapid prototyping, engineering assistance, and fast production turnarounds. Instead of merely meeting line size, DFT® specializes in producing in-line check valves that meet our customers’ specific requirements. As an engineered valve manufacturer, we have the capability to size to the application and solve unique problems by making adjustments to our valves to suit your application. DFT manufactures various styles of check valves in end connections such as flanged, wafer, threaded, and butt weld end.

DFT® can evaluate your valve sizing requirements and answer any questions you may have about our WLC® and ALC® valve product lines. Browse the ALC® and WLC® product pages, on dft-valves.com for more information.