Overview:

The city’s original wastewater treatment system was designed with three air-operated diaphragm (AOD) pumps at each of the eight scum houses – 24 AOD pumps moving scum and debris off the surface of the secondary clarifiers. The scum and debris constantly clogged the pumps. Additionally, during each power outage at the plant, additional clogs occurred when the solenoid valve (that controls the water fed into the pumps) became out of sync and resulted in downtime.

The city spent considerable time, labor, and money on the unscheduled maintenance at least four times weekly.

Eventually, these challenges caused the pumps to stop running, which led to a buildup in the piping and a solid layer formed on the clarifiers.

The plant needed a pump system capable of handling dirt, grit, and debris while maintaining sufficient capacity/flow for optimal pump performance, despite power outages.

Solution:

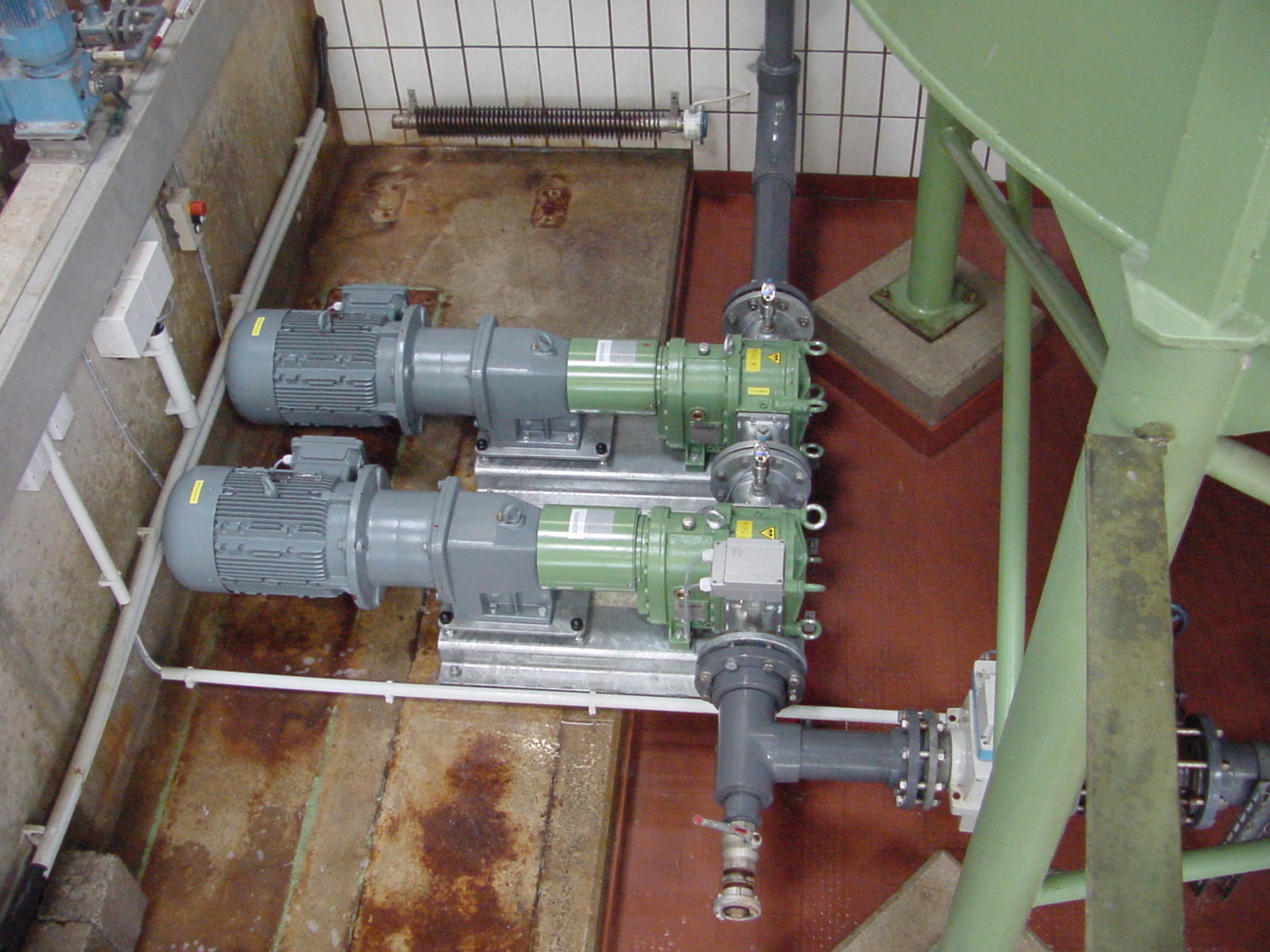

A duplex OverWatch® system was customized & installed to manage the scum layer for the two clarifiers and eliminated clogged pumps, improved operational efficiency, and reduced costly maintenance events. The system was designed with elongated legs to fit the existing footprint, and the control panel includes dry contacts to enable the solenoid valve operation using a mechanical timer that solves the power outage issue.

Adjustments to increase pump operation and efficiency:

- Minimum frequency was modified to prevent deadheading the pumps, ensuring the proper flow

- Ramp-up speed, or acceleration time, was increased for each pump, allowing the system to stabilize and avoid potential airlock issues

- Pumps were set to operate in a linear on/off mode, as flow was not frequent

- Scaling of the level sensor was adjusted to ensure accuracy when reading the liquid level

Since the OverWatch® system was installed:

- ZERO maintenance events

- ELIMINATED scum layer present on the secondary clarifier

- ZERO distribution to the solenoid valve time due to power outages

- INCREASED operator