In practical terms the pump must be filled beforehand with the fluid in question through a port on the pump casing (the chamber containing the impeller), after which it can be operated, creating a turbulence that allows the rise and free the pipes of the air.

There are different methods of inducing this self-priming process, the most common consists of creating in a tank parallel to the line, of an equal or greater volume than the quantity of liquid necessary to fill the suction pipe and inserting a check valve upstream of the pump, to avoid having to repeat this operation each time that the machine is started.

In describing the self-priming concept we have intentionally referred to centrifugal machines. However there are different types of pumps that can be associated with this concept, in particular volumetric pumps (diaphragm, peristaltic, lobes, etc.).

Debem offers a range of double diaphragm volumetric pumps that are entirely air-operated. The operation of the Cubic and Boxer lines of pumps does not require the tank parallel to the pump.

See below for a brief description of the operation that renders the pumps of the Boxer range preferable to a normal electric pump.

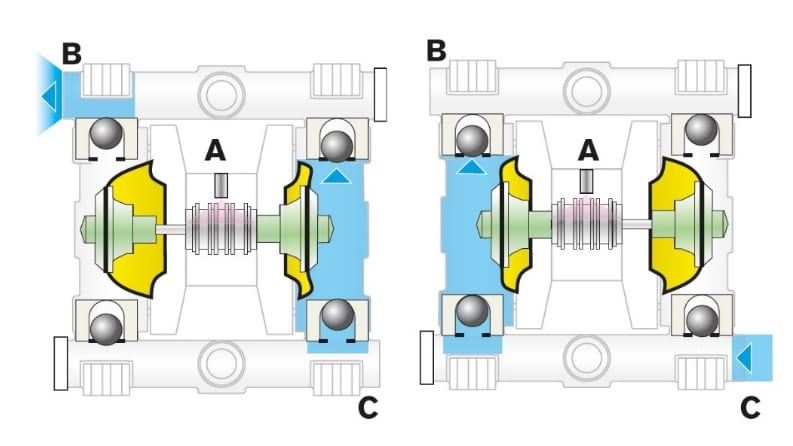

Situation 1: the diaphragm retracts (left image) creating a vacuum, the ball in suction is raised by the pull of the fluid and allows the fluid (and air, when starting the pump) to fill the chamber.

Situation 2: the diaphragm inflates (right image) and pushes the fluid out of the pump, lifting the ball in delivery and, at the same time, presses the ball in suction down, closing the passage.

This type of operation ensures the suction of the fluid even when the pump is not flooded, exploiting the movement of the balls that are used as check valves (even though they are not, as they don’t always ensure an hermetic and long-lasting seal) in creating the vacuum inside the suction pipes.

The above does not differ in the end, compared to a normal centrifugal pump, except for the fact that the diaphragms have been designed and constructed to support the mechanical stress in the self-priming process each time that it is needed (even without the tank).