For this reason, hermetic systems such as canned motor pumps are often used to circulate refrigerant in large systems. In the food industry, cooling circuits with pumps are installed in various process steps. This includes the production and conveyance of food as well as the storage of food at the correct temperature.

Your benefits:

- Absolute tightness of the system even when using refrigerants with high demands such as ammonia or CO2

- Prevention of plant downtimes thanks to high maintenance cycles

- Emergency stock for quick replacement deliveries of the standard product range

Typical areas of application:

- Ice cream production

- Breweries

- Dairies

- Abattoirs

- Fish processing

- Frozen food production

- Freeze-drying

- Freezing tunnels

- Climate control

Ice cream Production Requirements

In this application, the focus was on ensuring smooth production operations and a fast response time in the case of unexpected plant downtimes. Production is continuous. Therefore, the maintenance of the plant must be reduced to a minimum. Leakage of cooling liquids must also be prevented so that the ice cream is not contaminated.

| Delivery rate: | 27 m3/h |

| Pumping head: | 55 m |

| Operating temperature: | –45 °C |

| Refrigerant: | Ammonia |

| System type: | Ammonia refrigeration technology |

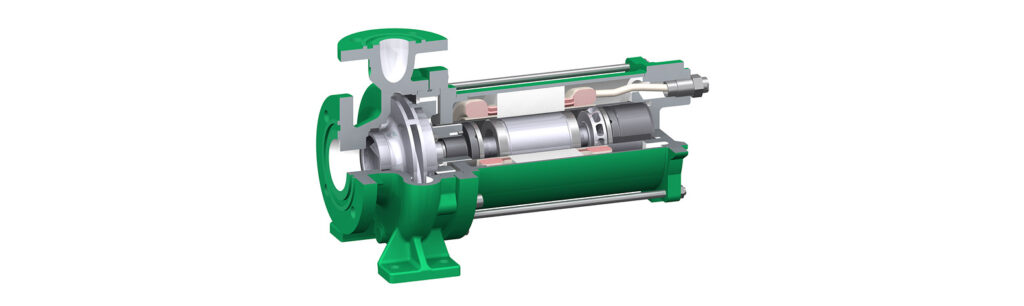

The pump used

The canned motor technology impressed the customer with the highest safety standards against leakage and the two safety shells. A standard HERMETIC canned motor pump of type CNF40-200 with AGX6.5 motor was used in the system. This is a single-stage canned motor pump available as a standard stock item in the case of emergencies. The single-stage pump series is particularly suitable for high delivery rates and medium pumping heads. A Qmax orifice made it possible to achieve exactly the desired operating point and the maximum delivery rate at the same time.

The customer was also particularly impressed by the long, maintenance-free service life and the stock availability in emergencies.