Decades of experience, countless international projects and trend-setting innovations generated a vast range of VARIVENT® products and options.

LEFF® technology from GEA saves up to 90 percent on cleaning media

GEA VARIVENT® Mixproof Valves are the core component in matrix-piped process plants. They offer flexible valve concepts, innovative control functions and facilitate considerable cost savings.

Especially the LEFF® technology in GEA VARIVENT® Mixproof Valves provides up to 90 percent savings in clean-in-place media (CIP) such as expensive cleaning agents, water and waste water. LEFF stands for Low Emission Flip Flop. The LEFF® function is integrated in the T.VIS® A-15 valve control top and can be easily activated. The intermittent movement of the valve disk significantly improves cleaning efficiency. Staggered CIP cleaning of the individual valve housings means these valves can be used around the clock, without ever having to entirely shut down production.

Optimum cleaning of the valve seats and the valve chamber

Cleaning the cavity of the VARIVENT® Mixproof Valve takes place while product is present in the opposite valve housing. There is never a worry of intermixing.

Accurate control of valve seat lift position is made possible by LEFF®, so only a narrow opening between the valve disk and seat is created during cleaning. This narrow opening causes the CIP liquid velocity to increase, producing an optimum cleaning burst in the seat area and vent cavity. The result is superior cleaning using a minimal amount of CIP media.

To use the LEFF® function, no complicated programming in the higher-level control (PLC) is required. The LEFF® function works independently of process run times and product pressures. There is automatic monitoring of the lifting functions.

With mixproof valves, only the standard feedback units are used. No special components are required. The rectilinear configuration with two push-buttons on the T.VIS® bonnet allows separate activation of the LEFF® function at any time when setting the valve. Activation of the upper seat function requires an external proximity switch.

Shear forces optimally exploited

Sealing zones on the valves can be cleaned separately by LEFF® with their sealing function entirely retained. This means that they can work around the clock, regardless of process run-times and product pressures, without interrupting production for CIP. “The principle is based on a flip-flop movement of the valve discs,” explains Bernd Porath, Product Manager for Hygienic Valve Technology at GEA. “At the moment when the valve disc lifts from the seat and opens up a cleaning gap, the cleaning medium flows in. That’s when the shear forces are at their greatest and they clean most effectively. We leverage this principle, and the closing and opening of the valve discs, in a very specific manner.”

No additional system planning and programming

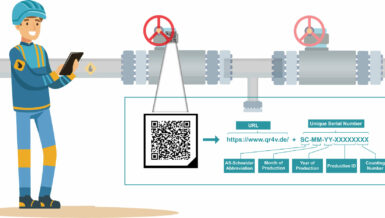

LEFF® is integrated as standard in the T.VIS® A-15 control head. Path-controlled electronics pulse-control the moment and degree of opening the valve disk with absolute precision. The electronic function monitors and controls the stroke of the valve seat via the valve’s path measurement system, independent of PLC scan times and line pressures. Since the electronic processing takes place only in the T.VIS® A-15 control top and not via the PLC, the signal speed is much faster.

Green light also from PMO Regulation of US Food and Drug Administration

Low emission flip-flop has already become standard in Europe for several major processing operations. In addition, the function has been approved by 3A for the use in PMO regulated plants. GEA is the first manufacturer of mixproof valves to meet the strict requirements of the PMO. The approval of Low Emission Flip Flop for the USA is a great success: “Water shortage is a critical issue especially in California. We are pleased to be able to help our customers in the USA with LEFF® by lowering water consumptions alleviating other cost pressure in their operations,” summarizes Bastian Tolle, Head of Product Group Management Flow Components at GEA.

Good news for existing customers in the United States as well: LEFF® is already integrated in the T.VIS® A-15 control head of the VARIVENT® 24/7 PMO 2.0 and only needs to be switched on to be used in existing applications. Additional system technology and programming are not required.