Aerating wastewater might be a so-called ‘Secondary Treatment’, but when foul odours create such an unpleasant environment, putting it right is very much a Primary concern.

If that stench is also upsetting your neighbours, then you might well find yourselves on the end of Environment Agency visits, and a wave of unwelcome bad publicity as those in the local area, armed with social media, will be quick to tell the world that:

“It’s been going on for ages!”

“None of us can open our windows!”

And that you, the reason behind the foul odours “Just doesn’t care!”

The offending tank(s) in your effluent treatment process may already have a pump or mixer. And with no shortage of noise and surface bubbles, there perhaps appears to be plenty of oxygen to feed all the bacteria so that it biodegrades. But what lies beneath?!

If you’ve reached that point where everyone is having to hold their nose, then there’s a strong likelihood that the tank is not being mixed properly. Accumulated rotting solids will be sitting on the floor of the vessel, generating that awful rotten smell.

To make a sweeping statement, ‘most pumps can deal with most wastewaters’, until hard-to-handle solids come along. As well as foul odours, you’ll be entering a world of pain with blocked pumps, downtime, rising maintenance costs, and possibly an overflowing tank.

Logic would therefore suggest that it is a false economy to buy ‘a standard pump’. Instead, invest in one that is much tougher, longer lasting; designed to continuously reduce particle sizes, and doesn’t come to a grinding halt when larger solids inevitably creep into the wastewater process.

A Chopper Pump might well be the solution. Speaking for Landia, who invented the world’s first Chopper Pump back in 1950, Technical Sales Engineer, Howard Burton has no shortage of success stories to put forward.

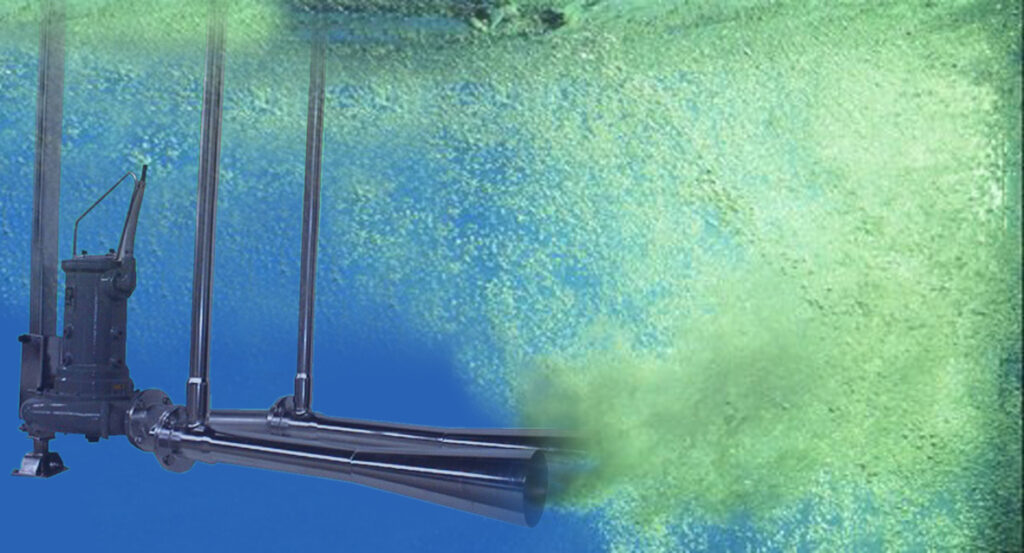

“Our Chopper Pump has a pretty nasty knife system that stops solids from entering the casing,” he said, “so we’re always confident that it can handle tough applications. We use the Chopper Pump with angled venturi nozzles to create our AirJet system so that the whole tank gets mixed comprehensively.”

Howard pointed to a Landia problem-solving job at the renowned Timothy Taylor’s brewery in North Yorkshire. A survey by wastewater treatment provider, Ogden Water, showed that the pumps used for the brewery’s 45m3 balance tank were not providing enough agitation to adequately keep solids in suspension.

‘Eliminate odours caused by solids not being sufficiently suspended’

Nick Berkovits, Second Brewer at Timothy Taylor’s, commented:

“Ogden Water’s rigorous survey showed that an upgrade to superior aeration equipment would eliminate odours caused by solids not being sufficiently suspended and also provide a much more consistent homogenous feed to our DAF (Dissolved Air Flotation) unit.”

Food processors often have odour problems with poorly aerated tanks. KK Fine Foods (based in North Wales) have had their Landia AirJet system (on a 328m3 glass-lined steel tank) for over seven years. Dave Edmunds, Engineering Manager said:

“We’ve only just had to replace a few basic wear and tear parts on the system, which shows how reliable it is. The AirJet is something of an unsung hero. It sits there and does its job very well indeed.”

In addition, a leading producer of cereals and cereal bars turned to Landia for help due to high levels of FOG (fats oils and greases) caused by ingredients such as chocolate, rape seed oil and lecithin (phospholipids). At one point COD (Chemical Oxygen Demand) had risen to 78,000.

Karl Johnson, Safety, Heath & Environment Manager at Deeside Cereals, commented:

“When our sugary water used to become entrained, it was very challenging to treat and fulfil our compliance obligations. We’ve found that it is easier to control the COD by only half filling our tank, but we always test it before discharge – and if needs be, can aerate the effluent a little longer until it is below our compliance threshold. The Landia pump needs nothing more from us than a quick visual inspection each day to check on oil.”

Howard Burton from Landia added: “The AirJet also removes or massively reduces the cost and labour of having to add chemicals. And with today’s scary energy prices, it is far more economic than using electricity-guzzling blowers.”