In 1994, when the disk aerators in the treatment plant’s circular aeration basin were no longer providing adequate results, the acclaimed National Guard base (established for over a century) called in Marlar Engineering (now part of Halff Engineering) to address their effluent problems.

‘Tremendous amount of infiltration’

“In addition to the age of the 500,000 gallons per day facility,” said Mike Marlar, now Vice President of Hallf Engineering, “the site also had a major problem with the tremendous amount of infiltration that was getting into their system. During the wet weather season, this was often as much as seven times the design flow, so no wonder they kept failing to meet compliance.”

He added: “The military base, which has numerous arms ranges and premier training facilities, also wanted to immediately double the capacity of their wastewater treatment plant because of a big rise in the number of recruits.

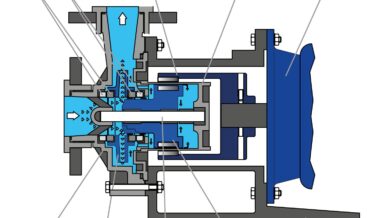

“After considering all the options, and thoroughly doing our homework, we specified an activated sludge oxidation process from Lakeside Equipment Corporation. We built two oxidation ditches side by side (with covered Magna Rotors) for a total design flow of one million gallons per day. It really says something that three decades on, it is all still working very effectively. It has always met compliance. That’s some record!”

Marlar Engineering also undertook a complete rehabilitation of the collection system; introducing a new headworks facility with a diversion box, so that when heavy wet weather flow reached critical levels, it was diverted into a new equalization basin, which was designed to hold 1.5 million gallons per day. When the weather improved, with less severe rainfall, the sewage could then be diverted back up through the head of the plant for treatment.

Aerated wastewater was set up to flow to two clarifiers that operate in a series operation to settle out the solids, before the effluent is then further polished by a tertiary (Dynasand) filtration process. Coliform and fecal coliform bacteria were then treated by one of this US States’s first ever ultraviolet (UV) light disinfection system. Parshall flumes on both the influent and effluent ensure that wet weather flows can be comprehensively monitored. Sludge was initially dried through a reed bed process; more recently changed to sand drying.

Mike Marlar continued: “When the plant first went online in 1995, it won the National Guard Bureau’s Environmental Award. In 30 years, we’ve only had one upgrade project, which was a little over 10 years ago in 2015. This was simply to replace some of the UV lights and some minor pieces of equipment. It has all been a very stable process indeed. The National Guard are rightly very pleased with it.

“We oversee the operation and maintenance of the treatment plant and have had a licensed operator on site since its inception.

‘It has a phenomenal record’

“In terms of numbers,” he concluded, “and the likelihood of failures, there are just two Lakeside Rotors, whereas some aeration basins can have anything from 20-40 diffusers, which will inevitably mean more maintenance and more replacement parts. But it has to be said, and I’ve now had over 30 years’ first-hand experience of seeing Lakeside’s equipment in operation, that at this military base and at municipal plants all over America, that it is very well designed, extremely robust and built for easy maintenance. It has a phenomenal record. It all stacks up. In terms of longevity, I would say that at this National Guard base, it is in the top five per cent of all the many treatment plants I’ve ever been associated with.”