Problem:

- Space limitation

- Budget restraints

- Increased maintenance costs & downtime

- Re-purposing rainwater in a safe, environmentally friendly way

Overview:

Stark Environmental, LLC continues to prove that when it rains, it pours … into containment for future use as part of a cost effective, environmentally friendly system to recycle rainwater. The concept of rescuing rainwater to be re-purposed is not new. A recent project in the US Virgin Islands doubled down on rescue operations. A rainwater and reuse system was specified for the Aircraft Rescue and Firefighting Facility at the Henry E. Rohlsen International Airport in St. Croix, USVI. So not only was the water rescued, it could then be used in the facility and for rescue operations. The system, which provides a maximum flow of 700 GPM for filling fire trucks, also provides water for toilet flushing and hose connections to wash equipment. Rainwater is collected from the 12,000-square-foot building roof and stored in a 50,000-gallon underground concrete cistern. Two separate pumping systems are located within the cistern to fill fire trucks and the other supplies the building for sanitary and cleaning operations.

“The St. Croix airport project required a tailor-made solution that maximized functionality in a limited space, met the project budget and minimized maintenance costs in a remote location.”

Solution:

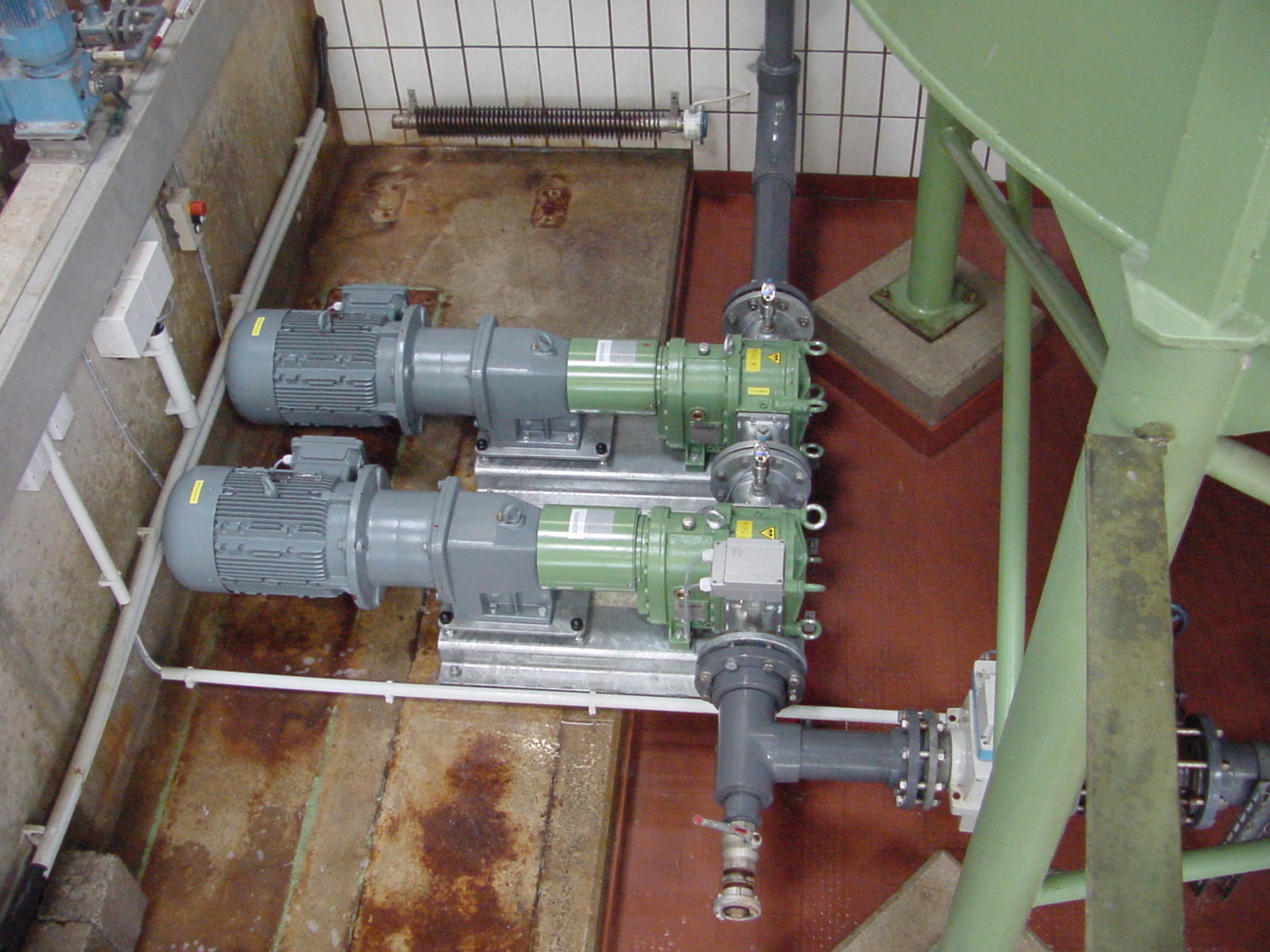

The solution was: Stancor dewatering pumps, manifolded together on a guide rail system, move water 500′ through an underground, six inch ductile iron pipeline that connects the cistern to the truck fill station. Three P40C HV pumps, with a Teflon coating for additional corrosion resistance, were specified to meet service expectations in a tropical island environment along with a small footprint. The system, which includes redundancies to support operations with life/safety implications, is managed by a customized control that alternates pump usage, verifies flow, maintains a hour log and includes a pedestal at the truck fill location to control pumps remotely.

“Our goal with every project is to unite an age old conservation practice with the latest technological advancements,” said Michael Stark, president of Stark Environmental. “The St. Croix airport project required a tailor-made solution that maximized functionality in a limited space, met the project budget and minimized maintenance costs in a remote location. Stancor pumps were chosen for multiple reasons. Submersible pumps could be placed within the cistern to eliminate the expense of building an additional pump enclosure. Stancor’s reputation for quality and use of high quality components, promised to provide a strong return on investment over the life of the project. And, finally, Stancor’s commitment to service-including design specification, installation support and product lead times-provided a strong partner to help us live up to our brand promise.”

Stark Environmental is a pioneer in rainwater collection and reuse systems. RainKeeper became its branded entity in 2008 and offers clients turnkey systems-including design, installation and operational services. Simplicity is at the heart of the RainKeeper approach. That applies to both the one-stop shop nature of its service and a design approach that minimizes system complexity to create cost-effective solutions.

“Projects like the St. Croix airport are incredibly rewarding,” said IFS Business Development Manager, “Contributing to the RainKeeper solution offered an opportunity to make a difference. Ensuring the right pumps were specified, and then properly installed, created an environmentally friendly solution that serves an invaluable purpose and does so in a manner that offers an extremely low-cost obligation.”

P/S Series Features:

- Cast 356 T6 aluminum motor housing

- Wear-resistant, nitrile rubble/wear plates

- Stainless steel handle and discharge connection

- Heavy-duty dewatering pump

- MSHA-rated version available

- High-chrome version available for high-wear resistance

P/S Series Typical Applications:

- General Dewatering

- Construction Dewatering

- Mine Dewatering