Two general principles rule at VA SYD: One is that even if water scarcity is not a problem in Sweden per se, wasting water just feels wrong. The other is, when it comes to new technology, to start small, try things out, and learn from failures to ensure success on a larger scale. The first principle was the motivation for establishing a leakage detection system. And the second principle defined the approach, namely, to establish a proof of concept in a relatively small section of the system with 5,000 consumers.

Small leaks with great impact

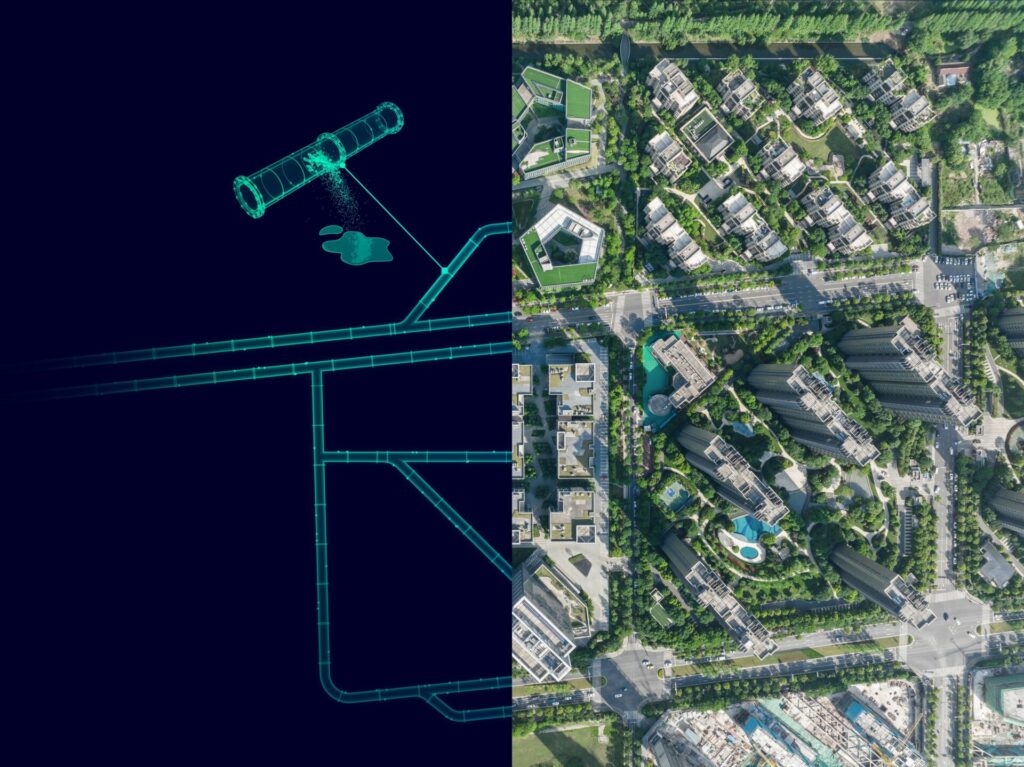

Based in Malmø, Swedish water supplier VA SYD operates a total of around 3107 miles (5,000 kilometers) of pipelines, 1243 miles (2,000 kilometers) of which are for drinking water. Pinpointing leaks is a complex task. “Until very recently, we could detect only the largest leaks that led to service disruptions. In fact, it is the smaller, slower leaks, often from small service pipes, that are responsible for the lion’s share of non-revenue water,” points out Simon Granath, Development Engineer at VA SYD.

Improved customer service

Another aspect is improving service to customers. “We have to maintain a lot of pipelines in a large area, and we wanted to improve our ability to pinpoint leaks through smart metering zones. For this purpose, we set out to find an AI-based solution,” recalls Simon Granath.

VA SYD evaluated several systems. Ultimately the solution would have to make optimum use of the available flow meters and smart meters in the area that had been chosen for the proof of concept. SIWA Leak Finder checked all the boxes. This smart solution uses an AI-based algorithm to identify and classify anomalies in the pipe network. To perform reliably, SIWA Leak Finder is first “trained” through historical flow and pressure data so that it learns to separate anomalies from regular operation and assign the correct cause to each anomaly.

Collaboration leads to an optimal AI solution

“But when it came to the implementation concept, we ran into some obstacles. We needed to find a way to use the AI-based leakage detection in an on-premises setup instead of in a cloud environment,” says Simon Granath. Siemens was able to offer a solution for this requirement as well. He continues: “We had some in-depth discussions with Siemens, BuntPlanet, and our IT and OT departments about the best approach to install the SIWA Leak Finder solution in our own data centers. To my knowledge, this is the first time something like this has been done in the Swedish water industry – and we managed to get the job done thanks not least to the support and expertise from Siemens.

This collaborative approach is typical of the Siemens ecosystem, where players from different industries and with different competences join forces to create real-world solutions. For SIWA Leak Finder, from the beginning an essential component has been BuntBrain, a software platform with solutions among others for leak detection. Initially Siemens licensed BuntBrain from its creator, BuntPlanet, before acquiring the company in December 2023.

Simulation approach for improved data

The next step was to refine the hydraulic models for the pipelines and link the data from the metering systems and pump stations with SIWA Leak Finder using OPC UA. VA SYD was then ready to perform the first tests. Simon Granath explains: “We used the system to simulate different leaks and then evaluated the data. We were able to detect leaks as small as 8 gallons per minute (0.5 liters per second)– this was quite impressive and a huge improvement over the previous solution, which provided no means of detecting small leaks at all.” Thus, non-revenue water in the drinking water network of VA SYD could be brought down from 10 percent to 8 percent.

Savings speak for the solution

With the proof of concept in its final stages, VA SYD is also working on scaling up the solution to other parts of the network. For example, the town of Lund, where VA SYD is installing additional flow meters to provide more data from the pipeline network.

Furthermore, the project at VA SYD has been widely recognized as a best practice in Sweden, leading other municipalities to adopt the same solution for water distribution in their respective areas. One such example is the Northwestern Skåne Water and Wastewater Utility (NSVA) in the southwestern part of the country. NSVA is benefiting from the expertise of Development Engineer Victor Pelin, who previously worked alongside Simon Granath to implement leakage detection at VA SYD.

Economic benefits aside, SIWA Leak Finder has already helped VA SYD take the next steps toward another ambitious goal: by 2030 the company wants to become a climate-neutral, energy-saving water utility with zero unplanned service disruptions.

VA SYD is well on the way with its current 8 percent non-revenue water. “We really want to beat that. There are municipalities that achieve much lower figures, and we want to be able to measure up to the best,” says Simon Granath. And for meeting that goal, there’s no way around smart leakage detection and AI-based solutions like SIWA Leak Finder.