Each flowmeter converts flow into an output signal, an ultrasonic flowmeter uses the speed of sound through a flowing medium. In the electronics of an advanced flowmeter, a conversion is made from the raw measured data into the requested output signal, e.g. 0-20 l/min of liquid-flow is converted to 4-20 mA.

Customized damping of the output signal

With 250 measurements per second, an ultrasonic flowmeter will follow even minor fluctuations in flowrate, updating its output value at a frequency of 250 adjustments each second.

This may sound interesting, in practice it is a very nervous signal.

To increase usability, the output signal is dampened. Instead of outputting each theoretically possible value, the mean-value of x measurements is calculated and communicated to the outside world.

The factor x is customizable, resulting in a lower or higher damping-factor.

An optimized damping-factor will make the difference in any application.

A flow-controlled loop may require a higher factor to keep a steady flow, where a fast dosing process will function better with a low factor.

Signal damping by the medium

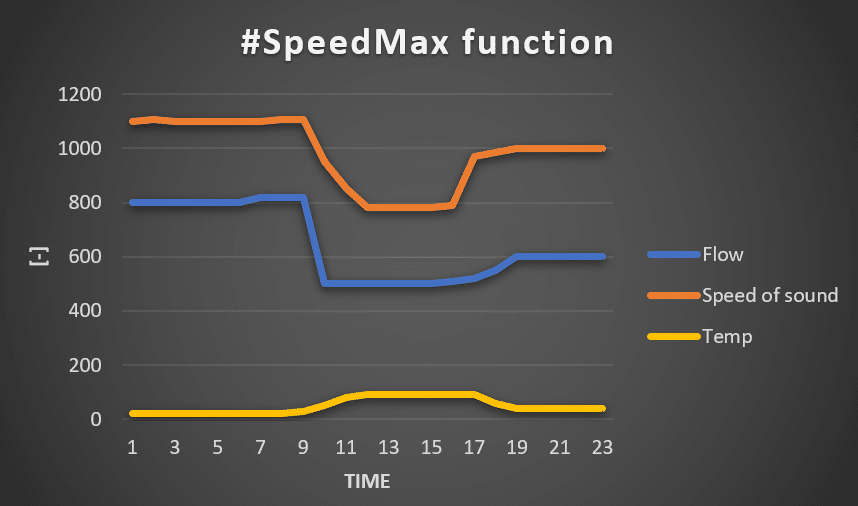

Another occurrence in ultrasonic flow-measurement is the damping-factor as a property of the liquid. Each liquid has a different effect on the speed of sound through this medium. Knowing that an ultrasonic flowmeter measures the signal travelling time through the liquid, the actual speed of sound is usable as an indicator of the fluid inside the measuring tube. This is particularly interesting in processes where for example multiple media are measured, with intermediate rinsing or chemical cleaning of the system (CIP).

The ultrasonic flowmeter will log the flowrate and measured volume of the different media, including the cleaning cycles.

Such a log-file provides the process-owner all required traceability data.

Combining the speed of sound recordings with a temperature registration makes the log-file complete. Anyone can see what has happened and be sure that the intended cleaning and rinsing went according to plan. This traceability aspect is a valuable asset, generated by sensors already integrated in the flowmeter.

Bonus: A third effect of signal damping

Your liquid may be sensitive to gas-bubbles that can form under certain circumstances. A high amount of gas-bubbles inside the measuring tube will dampen out the measuring signal in such an extent that the electronics decide to raise an alarm. The deteriorated measurement-signal is functioning as a gas-bubble-detection. A similar alarm will be given when there is no liquid at all inside the measuring tube.

Conclusion

A smart choice may deliver more information than just flow!

The above three examples prove that it makes sense to collect good advise before selecting a flowmeter for your process. Flowmeister can advise you on the range of Flowmax instruments, a portfolio of high-end, plastic body flowmeters in industrial, chemical and Single Use versions.